Testing method for mixing degree of iron ore pellet mixture

A test method and technology of iron ore pellets, applied in the field of iron ore sintered pellets, can solve the problems of inability to quantitatively describe powder uniformity, complex element content determination by secondary methods, and high test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The specific steps of the measurement method are as follows:

[0066] (1), take one set of moisture measuring instrument (infrared (halogen) moisture analyzer (model MS-100, Harbin Yuda Electronic Technology Co., Ltd.), a plurality of sampling sealed bags;

[0067] (2) Sampling in subregions in the mixed material of the pellet raw materials to be tested. In order to prevent water evaporation and ensure the validity and reliability of the samples, the sampling area should be in the vertical intensive mixer as a primary mixer (i.e. iron ore pellets) mixing equipment) within 10m of the material outlet and divide the interval into 8 equal-length sampling sections, take samples from each section simultaneously or synchronously, and then package the samples obtained in each section in step (1 ) in a sealed bag, take 8 samples, the number of samples is recorded as N=8, and the weight of each sample is not less than 10g;

[0068] (3), from the sample taken in step (2), take pa...

Embodiment 2

[0076] The specific steps of the measurement method are as follows:

[0077] (1), take a moisture measuring instrument (Kesaisi microwave moisture meter, MSF-300, Beijing Kesaisi Technology Co., Ltd.), a plurality of sampling sealed bags;

[0078] (2) Sampling in subregions in the mixed material of the pellet raw materials to be tested. In order to prevent water evaporation and ensure the validity and reliability of the samples, the sampling area should be in the vertical intensive mixer as a primary mixer (i.e. iron ore pellets) mixing equipment) within 10m of the material outlet and divide the interval into 6 equal-length sampling sections, take samples from each section simultaneously or synchronously, and then package the samples obtained in each section in step (1 ) in a sealed bag, take 6 samples, the number of samples is recorded as N=6, and the weight of each sample is not less than 10g;

[0079] (3), from the sample taken in step (2), take part of the material respec...

Embodiment 3

[0087] Sampling at time intervals. The specific steps of the measurement method are as follows:

[0088] (1), take a moisture measuring instrument (Guanya infrared moisture analyzer, SFY-20, Shenzhen Guanya Electronic Technology Co., Ltd.), a plurality of sampling sealed bags;

[0089] (2), at the material outlet of the vertical intensive mixer (i.e. iron ore pellet mixing equipment) as a primary mixer, take 10 samples and encapsulate them in sealed bags respectively at an interval of 5 seconds, take 10 samples, and sample The number is recorded as N=10, and the weight of each sample is not less than 10g;

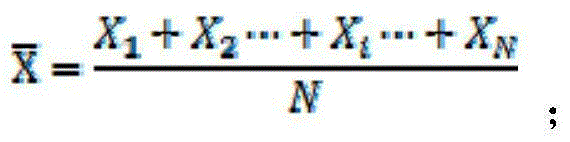

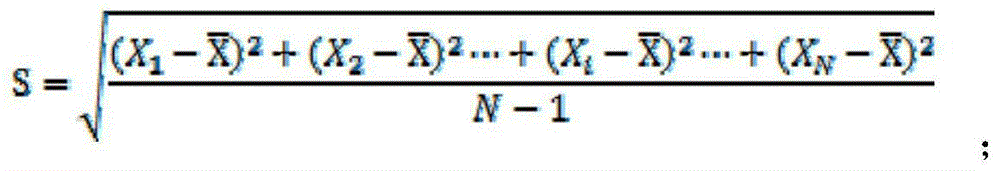

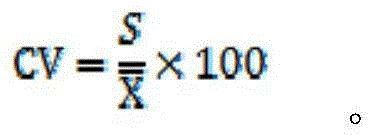

[0090](3), from the sample taken in step (2), take part of the material respectively in the moisture measuring instrument in step (1), test its moisture content, the moisture content percentage of each sample, that is, divide the moisture mass by the measured sample mass, recorded as X i , i=1, 2, 3, 4, 5, 6, 7, 8, 9, 10;

[0091] (4), the water content of N samples mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com