A method for smelting manganese-ferroalloy by heating manganese ore with microwave

A ferromanganese alloy and microwave heating technology, which is applied in the field of metallurgy, can solve the problems of slow heating rate and long heating time, and achieve the effects of promoting reaction, fast heating rate and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

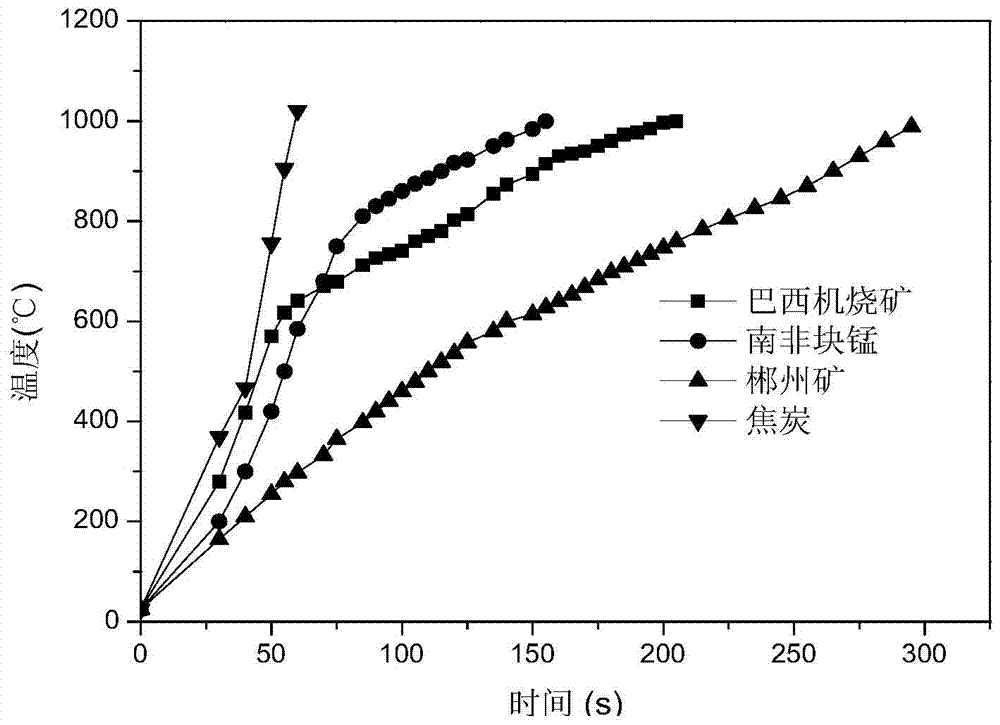

[0029] Example 1: In order to verify the microwave absorption characteristics of raw materials in the microwave field, microwaves with a power of 4KW and a frequency of 2.45GHZ were used to heat Brazil sintered ore, South African lump manganese ore, Chenzhou lump manganese ore, coke, etc., and the microwave power of a single raw material was 4KW, and the frequency was 2.45GHZ. The comparison of the heating characteristics in the microwave field is shown in Table 4, and the heating curve is shown in figure 1 . Depend on figure 1 It can be seen from Table 4 that the four raw materials for smelting ferromanganese can be heated in microwave, and all have good microwave absorption properties, and can quickly heat up in a short time, indicating that it is feasible to use microwave to heat ferroalloy raw materials.

[0030] Table 4 Comparison of heating characteristics of a single raw material

[0031]

Embodiment 2

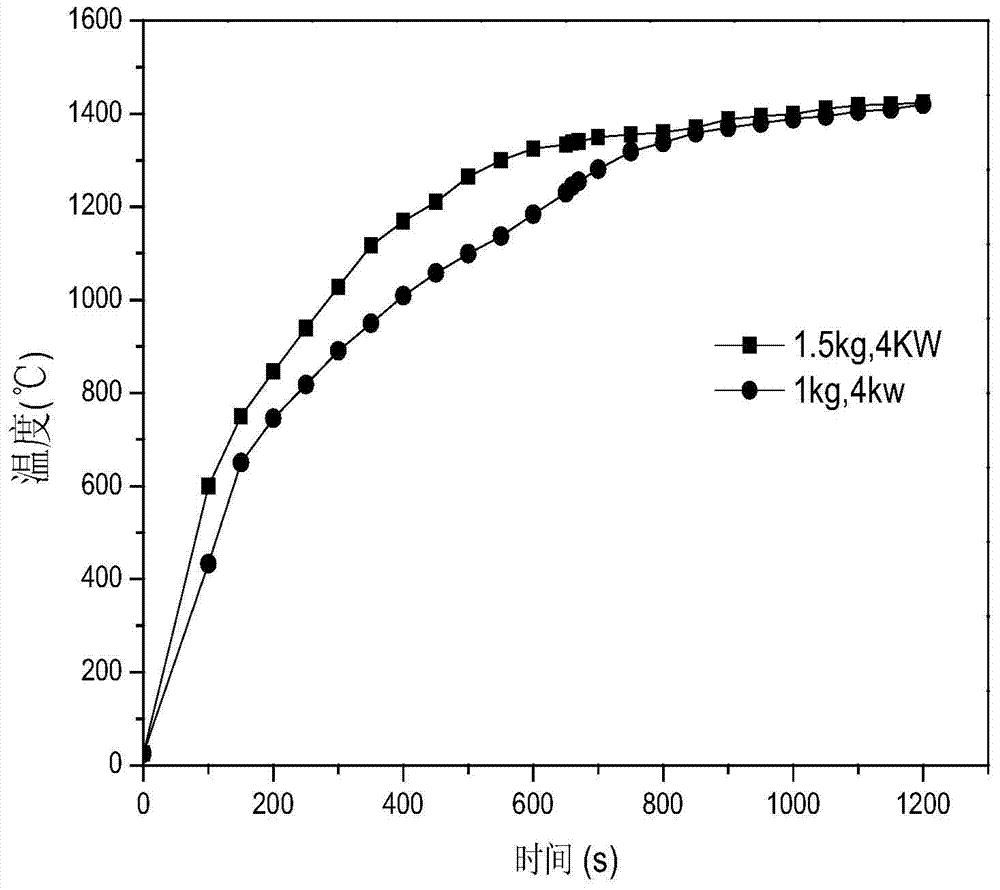

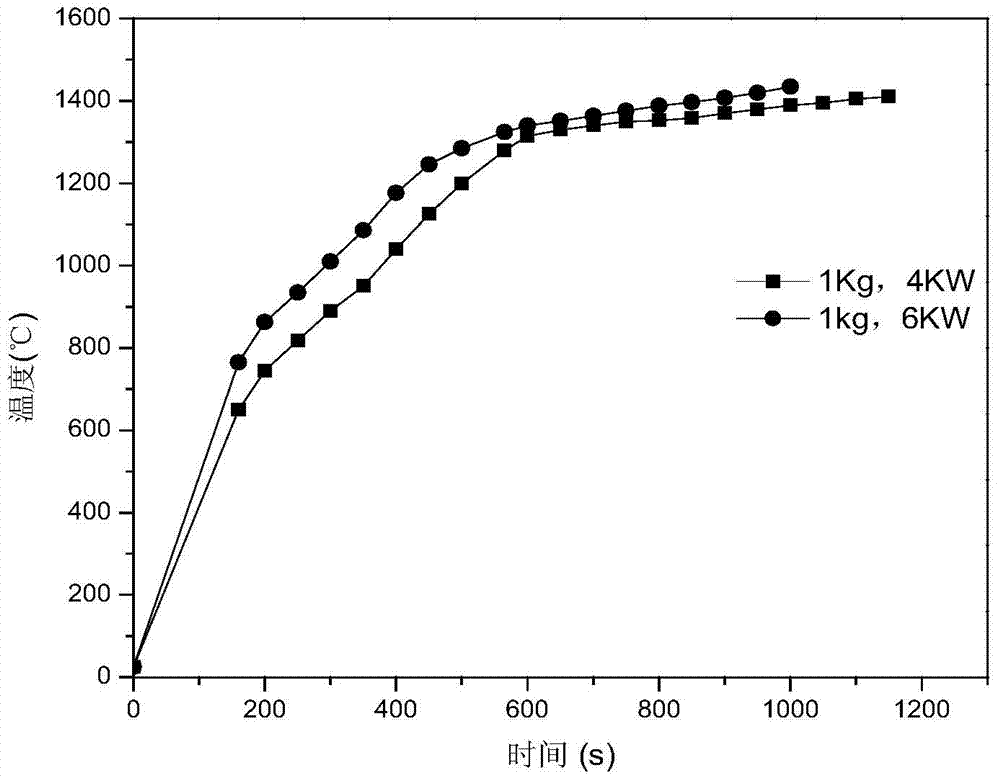

[0032] Embodiment 2: set the microwave power to 4KW, and the frequency is 2.45GHZ, weigh 1kg of raw materials according to the batching method in Table 2, the oxygen-carbon molar ratio in the batching is 1:1.5, put the raw materials into the inside of the crucible naturally and loosely, and start heating. Raise the temperature to 1450°C, adjust the microwave power to enter the heat preservation mode, and keep the heat for 60 minutes to smelt ferromanganese. After the heat preservation is over, turn off the microwave and cool down.

Embodiment 3

[0033] Embodiment 3: Set the microwave power to 4KW, the frequency to 2.45GHZ, weigh 1.5kg of raw materials according to the batching method in Table 2, the oxygen-carbon molar ratio in the batching is 1:1.6, put the raw materials into the crucible naturally and loosely, and start heating , raise the temperature to 1500°C, adjust the microwave power to enter the heat preservation mode, hold the heat for 90 minutes, and carry out the smelting of ferromanganese. After the heat preservation is over, turn off the microwave and cool it down.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com