Method and system for recovery of valuable metals from red mud

A valuable metal, red mud technology, applied in the chemical industry, can solve the problems of increasing the comprehensive utilization rate of red mud, high alkali content, low product added value, etc., to achieve the effect of broadening the utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

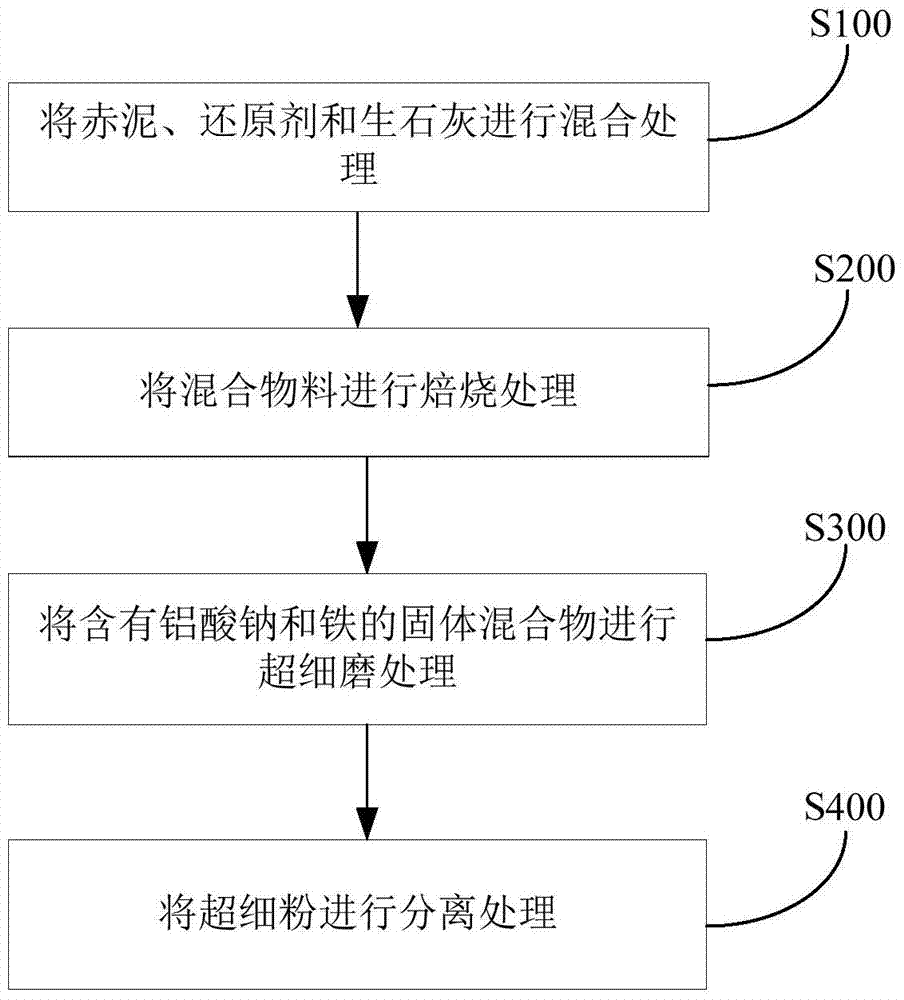

[0068] Red mud, reduced coal and quicklime are mixed and batched, wherein the mass ratio of red mud, reduced coal and quicklime is 100:20:20, and then the obtained mixed batch is rolled and mixed to obtain a mixed material, and then the mixed material is formed Treatment to obtain mixed pellets, and then roast the mixed pellets at 1150°C to obtain sodium oxide and a solid mixture containing sodium aluminate and iron, and then ultrafinely grind the obtained solid mixture containing sodium aluminate and iron Process to obtain ultrafine powder, wherein, the particle diameter in the ultrafine powder is not higher than 0.056 mm and accounts for 80wt% of the total ultrafine powder, and then the gained ultrafine powder is carried out to wet magnetic separation to obtain iron products (iron content greater than 87wt%) ), sodium aluminate solution and tailings, wherein the sodium oxide in the tailings is 0.9wt%, TFe is lower than 15wt%, and calculated according to the sodium oxide in re...

Embodiment 2

[0070] Red mud, reduced coal and quicklime are mixed and batched, wherein the mass ratio of red mud, reduced coal and quicklime is 100:20:25, and then the obtained mixed batch is rolled and mixed to obtain a mixed material, and then the mixed material is formed Treatment to obtain mixed pellets, and then roast the mixed pellets at 1200°C to obtain sodium oxide and a solid mixture containing sodium aluminate and iron, and then ultrafinely grind the obtained solid mixture containing sodium aluminate and iron Process to obtain ultrafine powder, wherein, the particle diameter in the ultrafine powder is not higher than 0.056 mm and accounts for 85wt% of the total ultrafine powder, and then the gained ultrafine powder is carried out to wet magnetic separation to obtain iron products (iron content greater than 90wt%) ), sodium aluminate solution and tailings, wherein, the sodium oxide in the tailings is lower than 0.7wt%, and TFe is lower than 13wt%. According to the calculation of so...

Embodiment 3

[0072] Red mud, reduced coal and quicklime are mixed and batched, wherein the mass ratio of red mud, reduced coal and quicklime is 100:25:30, and then the obtained mixed batch is rolled and mixed to obtain a mixed batch, and then the mixed batch is mixed at 1200 Roasting treatment at ℃ to obtain sodium oxide and a solid mixture containing sodium aluminate and iron, and then subject the obtained solid mixture containing sodium aluminate and iron to ultrafine grinding to obtain ultrafine powder, among which, the ultrafine powder is medium-sized Those whose diameter is not higher than 0.056 mm account for 90wt% of the total ultrafine powder, and then the obtained ultrafine powder is subjected to wet magnetic separation to obtain iron products (iron content greater than 90wt%), sodium aluminate solution and tailings, wherein the tailings The sodium oxide in the medium is lower than 0.55wt%, and the TFe is lower than 13wt%. According to the calculation of sodium oxide in red mud and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com