A Method of Regulating the Load of Circulating Fluidized Bed Boiler

A circulating fluidized bed and boiler load technology, which is applied in the directions of fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, can solve the problems of small load adjustment range, low combustion efficiency, and low ash content, and can achieve load The effect of large range adjustment, improved combustion efficiency, and increased peak shaving capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

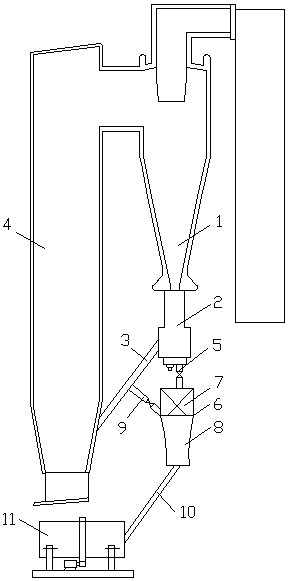

[0044] see figure 1 , a method for adjusting the load of a circulating fluidized bed boiler, comprising an ash returning step and an ash removing step, and also includes an ash adjusting step and an ash feeding step, wherein the ash returning step refers to connecting an ash return device at the bottom of the cyclone separator 1 2. Pass the ash in the ash return device 2 into the furnace 4 through the ash return pipe 3; valve, the high-temperature ash enters the ash regulator 6 through the ash discharge pipe 5 connected to the ash return valve, and the cold ash chamber 7 in the ash regulator 6 cools the high-temperature ash, and then introduces the fluidization wind into the venturi of the ash regulator 6 The fluidization air chamber 8 forms a fluidization wind with a high-pressure flow rate, and the fluidization wind performs secondary cooling on the high-temperature ash, opens the isolation valve on the ash return pipe 9, and blows the low-temperature ash after the temperatu...

Embodiment 2

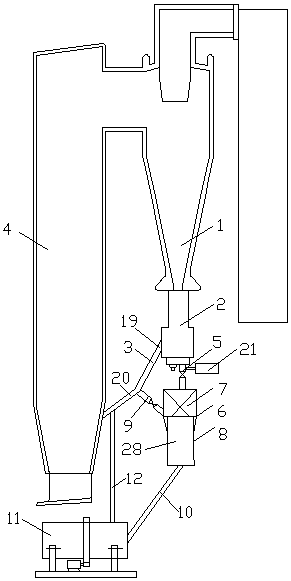

[0047] see image 3 , a method for adjusting the load of a circulating fluidized bed boiler, comprising an ash returning step and an ash removing step, and also includes an ash adjusting step and an ash feeding step, wherein the ash returning step refers to connecting an ash return device at the bottom of the cyclone separator 1 2. Pass the ash in the ash return device 2 into the furnace 4 through the ash return pipe 3; valve, the high-temperature ash enters the ash regulator 6 through the ash discharge pipe 5 connected to the ash return valve, and the cold ash chamber 7 in the ash regulator 6 cools the high-temperature ash, and then introduces the fluidization wind into the venturi of the ash regulator 6 The fluidization air chamber 8 forms a fluidization wind with a high-pressure flow rate, and the fluidization wind performs secondary cooling on the high-temperature ash, opens the isolation valve on the ash return pipe 9, and blows the low-temperature ash after the temperatu...

Embodiment 3

[0052] see image 3 , a method for adjusting the load of a circulating fluidized bed boiler, comprising an ash returning step and an ash removing step, and also includes an ash adjusting step and an ash feeding step, wherein the ash returning step refers to connecting an ash return device at the bottom of the cyclone separator 1 2. Pass the ash in the ash return device 2 into the furnace 4 through the ash return pipe 3; valve, the high-temperature ash enters the ash regulator 6 through the ash discharge pipe 5 connected to the ash return valve, and the cold ash chamber 7 in the ash regulator 6 cools the high-temperature ash, and then introduces the fluidization wind into the venturi of the ash regulator 6 The fluidization air chamber 8 forms a fluidization wind with a high-pressure flow rate, and the fluidization wind performs secondary cooling on the high-temperature ash, opens the isolation valve on the ash return pipe 9, and blows the low-temperature ash after the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com