Hot alkaline recycling device of calcining furnace

A recycling device and calcining furnace technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as environmental pollution and waste of resources, and achieve the effects of reducing raw material and energy consumption, production costs, and losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below by embodiment the present invention will be further described. It should be understood that the methods described in the examples of the present invention are only used to illustrate the present invention, rather than to limit the present invention, and any simple improvement to the preparation method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

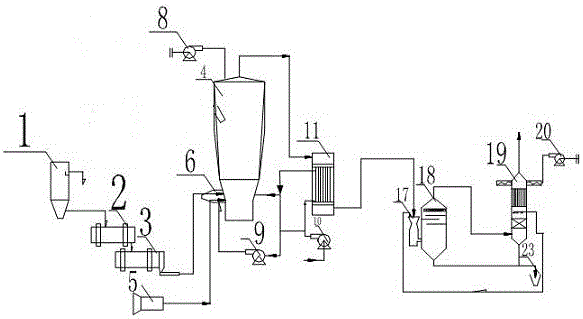

[0032] The calciner hot alkali recovery device of the present invention comprises a calciner, a stage separation device, and a washing device. The calciner includes a calciner 4, and the stage separation device includes a stage-by-stage separation 11. The passage of the stage-by-stage separation 11 is connected to the calciner 4. The top gas outlet is connected, and the passage of the first-level separation 11 is also connected with the washing device, and the passage of the first-level separation 11 is communicated with the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com