Liquid crystal module test system based on SOC FPGA

A technology of liquid crystal module and test system, applied in the direction of instruments, static indicators, etc., can solve the problems of limited test models and test requirements, users cannot freely edit and change, achieve flexible interface type support, reduce equipment failure rate, The effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

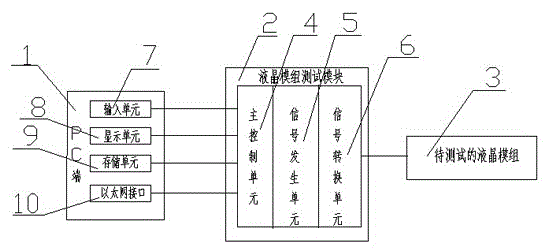

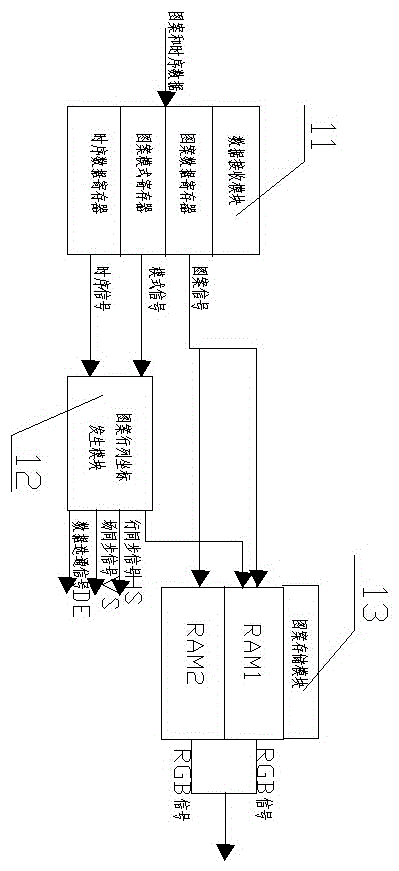

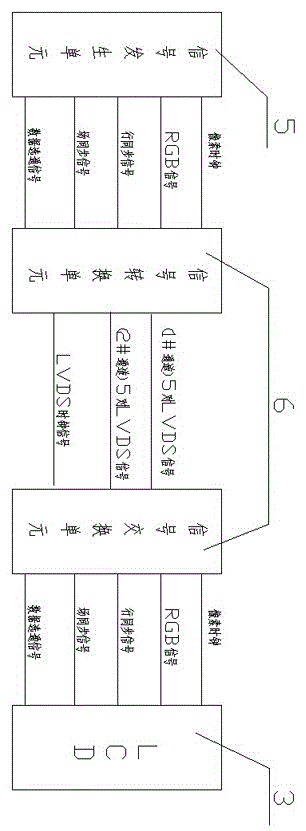

[0018] Such as figure 1 As shown, a SOC-FPGA-based liquid crystal module testing system of the present invention includes a PC terminal (1), a liquid crystal module testing module (2) and a liquid crystal module to be tested (3), and the liquid crystal module The test module (2) includes a main control unit (4) and a test signal generating device, and the test signal generating device includes a signal generating unit (5) and a signal conversion unit (6); Input unit (7), display unit (8), storage unit (9) and Ethernet interface (10) all carry out signal exchange with main control unit, and described main control unit (4) adopts SOC-FPGA built-in dual-core 1GHZ ARM is used as the main controller, and the main control unit (4) includes an LCD module timing editor, a test pattern editor and a test program editor, providing more than 128 groups of timing, 256 groups of patterns and 32 groups of tests Three pattern display modes of program, extension, copy and grayscale, color res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com