Refrigerator deodorizing material and preparation method thereof

A refrigerator, molecular sieve technology, applied in deodorization, separation methods, chemical instruments and methods, etc., can solve the problems of low odor degradation efficiency, low temperature, slow adsorption speed, etc., to improve market competitiveness, broad application prospects, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

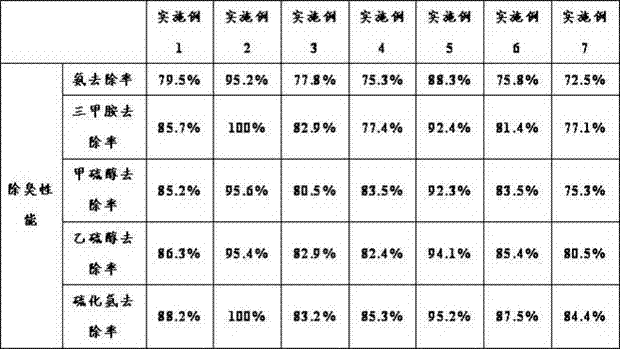

Examples

Embodiment 1

[0022] This example provides a kind of refrigerator deodorizing material, and it is prepared through the following steps:

[0023] (1) Add 50g of manganese sulfate, 30g of potassium permanganate, 80g of copper sulfate and 100g of magnesium chloride into 1000g of water. React at 20°C for 2.5h, cool down after fully reacting, add NaY molecular sieves for impregnation for 3.5h, then remove and dry at 100°C, after drying, calcinate at 320°C for 2h.

[0024] (2) Mix the calcined molecular sieve with coconut shell activated carbon powder at a ratio of 1:1, then add binder, lubricant and water, and extrude with a press and abrasive tools to obtain the refrigerator deodorizing material.

Embodiment 2

[0026] This example provides a kind of refrigerator deodorizing material, and it is prepared through the following steps:

[0027] (1) Add 50g of manganese sulfate, 40g of potassium permanganate, 100g of copper chloride and 100g of magnesium nitrate into 1000g of water. React at 20°C, cool down after fully reacting (reaction time 2.5h), add NaY molecular sieves for impregnation, impregnation time is 3.5h, then remove and dry at 100°C, dry at 350°C for 2.5h after drying.

[0028] (2) Mix the calcined molecular sieve with coconut shell activated carbon powder at a ratio of 0.9, then add binder, lubricant and water, and extrude with a press and abrasive tools to obtain the refrigerator deodorizing material.

Embodiment 3

[0030] This example provides a kind of refrigerator deodorizing material, and it is prepared through the following steps:

[0031] (1) Add 60g of manganese sulfate, 50g of potassium permanganate, 100g of copper nitrate and 100g of magnesium chloride into 1000g of water. React at 20°C, cool down after fully reacting (reaction time 2.5h), add NaY molecular sieves for impregnation, impregnation time is 3.5h, then remove and dry at 100°C, after drying, calcinate at 370°C for 2h.

[0032] (2) Mix the calcined molecular sieve with coconut shell activated carbon powder at a ratio of 1:1.1, then add binder, lubricant and water, and extrude with a press and abrasive tools to obtain the refrigerator deodorizing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com