Method for modification of polyurethane film for protective glass

A protective glass and polyurethane technology, applied in the field of polyurethane film, can solve the problem of low surface activity, achieve the effect of enhanced surface wetting ability, increased surface tension, and decreased contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

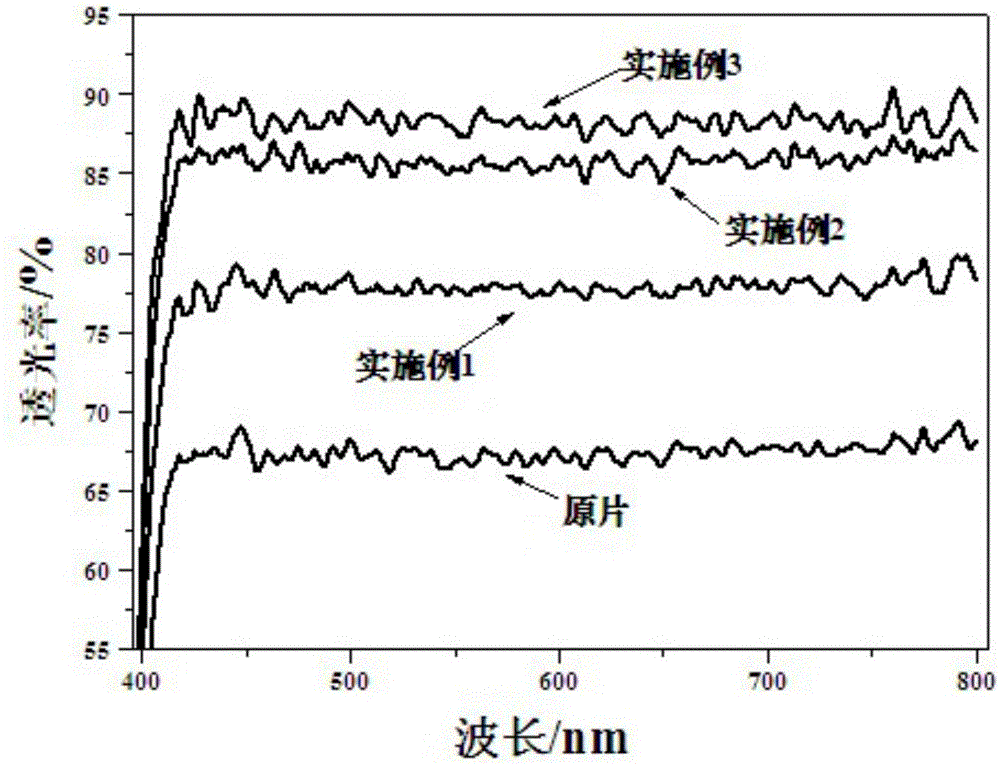

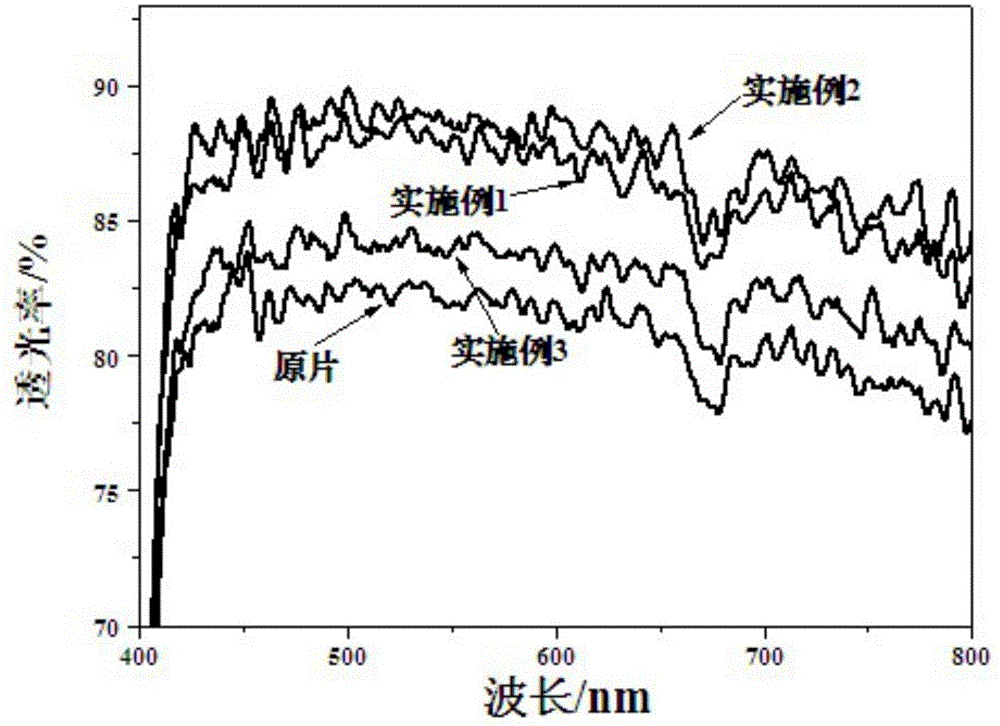

Embodiment 1

[0026] Polyurethane (PU) films were cut into 30 mm × 10 mm, put into absolute ethanol and deionized water and ultrasonically cleaned for 15 min, respectively, and the films were taken out, placed on petri dishes, and dried in an oven at 40 °C.

[0027] Use a balance to weigh the silane coupling agent KH550, absolute ethanol and deionized water according to the proportions of 1.3wt%, 95%, and 3.7wt%, respectively, and seal them in a beaker at a temperature of 30°C. Stir for 8 hours at a speed of 500 rpm to fully hydrolyze the coupling agent.

[0028] Put the washed and dried PU film into the dilute solution of hydrolyzed silane coupling agent KH550, and ultrasonically treat it for 1min at a temperature of 30°C. The treated film is ultrasonically cleaned with deionized water for 30min, and placed in an oven at 40°C. Medium dry.

[0029] Use the obtained PU film to bond with glass and polycarbonate (PC) to test the sample, place it in a vacuum oven at 120°C and a vacuum of 0.1MP...

Embodiment 2

[0032] Polyurethane (PU) films were cut into 30 mm × 10 mm, put into absolute ethanol and deionized water and ultrasonically cleaned for 15 min, respectively, and the films were taken out, placed on petri dishes, and dried in an oven at 40 °C.

[0033] Use a balance to weigh the silane coupling agent KH550, absolute ethanol and deionized water according to the proportions of 1.5wt%, 95%, and 3.5wt%, respectively, and place them in a sealed beaker at a temperature of 30°C. Stir for 8 hours at a speed of 500 rpm to fully hydrolyze the coupling agent.

[0034] Put the washed and dried PU film into the dilute solution of hydrolyzed silane coupling agent KH550, and ultrasonically treat it for 5 minutes at a temperature of 30°C, then ultrasonically clean the treated film with deionized water for 30 minutes, and place it at 40°C Dry in the oven.

[0035] Use the obtained PU film to bond with glass and polycarbonate (PC) to test the sample, place it in a vacuum oven at 120°C and a va...

Embodiment 3

[0038] Polyurethane (PU) films were cut into 30 mm × 10 mm, put into absolute ethanol and deionized water and ultrasonically cleaned for 15 min, respectively, and the films were taken out, placed on petri dishes, and dried in an oven at 40 °C.

[0039] Use a balance to weigh a certain amount of silane coupling agent KH550, absolute ethanol and deionized water according to the weight fraction of 1.7wt%, 95% and 3.3wt%, and place them in a sealed beaker at a temperature of 30°C. Under magnetic stirring for 8 hours, the rotation speed is 500rpm, so that the coupling agent is fully hydrolyzed.

[0040] Put the washed and dried PU film into the dilute solution of hydrolyzed silane coupling agent KH550, and ultrasonically treat it for 10 minutes at a temperature of 30°C, then ultrasonically clean the treated film with deionized water for 30 minutes, and place it at 40°C Dry in the oven.

[0041] Use the obtained PU film to bond with glass and polycarbonate (PC) to test the sample, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com