Liquid crystal aligning agent and liquid crystal display element

A technology of liquid crystal display element and liquid crystal aligning agent, which is applied in the direction of liquid crystal materials, optics, instruments, etc., can solve the problems of light and heat resistance, degradation, etc., and achieve excellent reliability, reduced manufacturing cost, and excellent display quality deteriorating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0162]

[0163] In the following synthesis examples, the synthesis operation of each polymer was repeated as necessary on the scale described below, thereby securing the required amount of polymers in the subsequent synthesis examples.

Synthetic example 1

[0165] The inside of the 500mL three-necked flask equipped with a three-way cock (three-way cock) and a stirrer equipped with a nitrogen gas introduction tube was set as a nitrogen atmosphere, and 20.00g (0.125mol) of 2,6-dihydroxynaphthalene, chlorinated After 0.58 g (0.125 mmol) of bis-μ-hydroxy-bis[(N,N,N',N'-tetramethylethylenediamine)copper(II)] and 380 mL of 2-methoxyethanol, stirring was started. Then, after adding 13.7 g of 31 wt % hydrogen peroxide water over 2 hours, it reacted at 25 degreeC with stirring for 3 hours. After completion of the reaction, the reaction solution was poured into 1,000 mL of distilled water to precipitate the product. The obtained precipitate was collected by filtration and recovered, and the solvent was removed overnight at 80° C. under vacuum, thereby obtaining a gray powdery polymer (A-1) (having the following formula (A-1) polymer of the indicated repeat unit) (yield 18.76 g, 95% yield).

[0166] [chemical 8]

[0167]

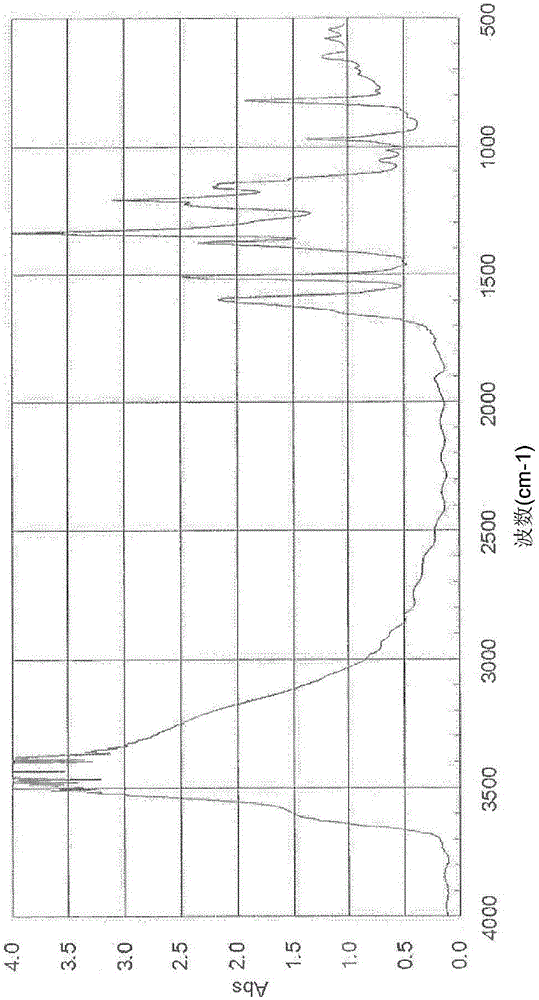

[0168] The ...

Synthetic example 2

[0173] According to the following Scheme 1, a polymer [polymer [A-4]] having a repeating unit represented by the formula [A-4] was synthesized.

[0174] [chemical 9]

[0175]

[0176] In a 500 mL eggplant-shaped flask, after dissolving 3.80 g of sodium hydroxide in 250 g of distilled water, 6.00 g of the polymer [A-1] obtained in Synthesis Example 1 was added and dissolved. ] under stirring to obtain the sodium salt of the polymer [A-1]. A solution obtained by dissolving 13.8 g of allyl bromide in 30 mL of ethanol was added dropwise thereto over 30 minutes at room temperature. After completion of the dropwise addition, reaction was carried out for 12 hours at room temperature with stirring. After the reaction was completed, the suspension-like reaction solution was suction-filtered to recover a solid. After washing the obtained solid with distilled water, vacuum drying was carried out at 50° C. to obtain 7.6 g of a polymer (polymer (A-4)) having a repeating unit represen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com