Method for sterilization of medium for production of sodium gluconate by Aspergillus niger fermentation

A technology of sodium gluconate and medium sterilization, applied in the direction of fermentation, can solve problems such as large steam consumption, and achieve the effects of improving fermentation efficiency, reducing residual sugar and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

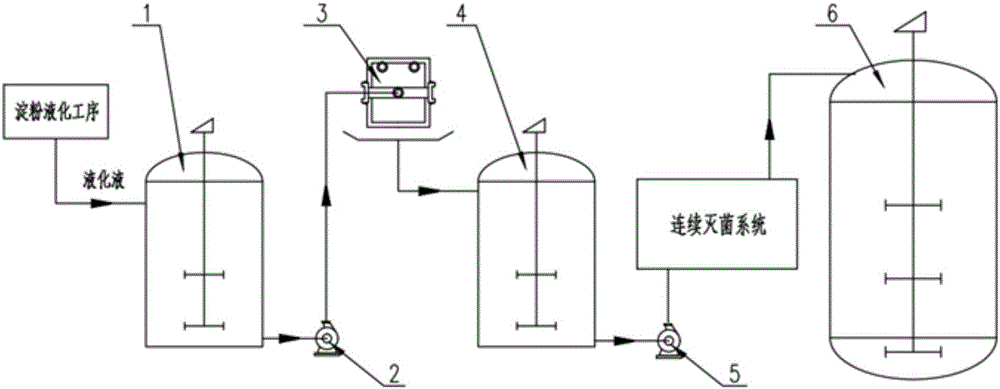

[0026] Example 1 300m 3 Fermentation Medium Continuous Sterilization Technology

[0027] 1) Dilute the starch milk with water to a mass concentration of 32.8% (w / v), adjust the pH value to 5.5, add liquefaction enzyme in proportion, heat up to 105-108°C instantaneously through the injector, enter the maintenance tank, and maintain at 105°C for 5 minutes , and then enter the medium temperature maintenance tank through the flash tank, maintain 1h-1.5h at 95°C-98°C, then heat up to 125°C-130°C through secondary spraying, maintain 125°C for 5min, and cool the material to 62°C through a heat exchanger , enter the saccharification tank, add acid to adjust the pH to 4.5, add saccharification enzyme preparation in proportion, and keep saccharification at 60°C-62°C until the saccharification is completed.

[0028] 2) After the saccharification is completed, the saccharification liquid is filtered through a filter, and the obtained clarified sugar liquid is pumped to the batching tank....

Embodiment 2

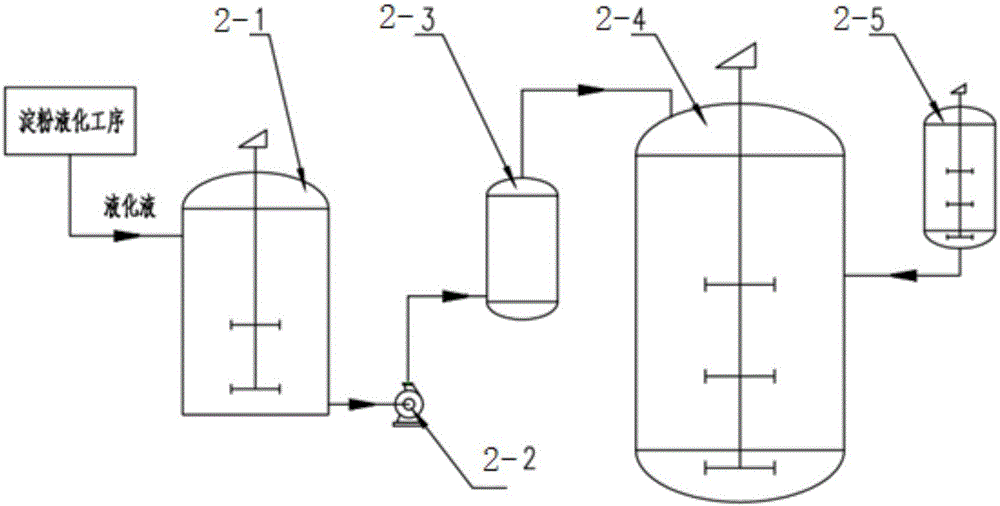

[0034] Example 2 300m 3 Basic invention of fermentation culture Sterilization process

[0035] 1) Add water to the commercial starch or dilute the starch milk to a mass concentration of 33.5% (w / v), adjust the pH value to 5.6, add liquefying enzyme in proportion, and heat up to 105-108°C instantaneously through the injector, then enter the maintenance process Tank, maintained at 105°C for 5 minutes, then enters the medium temperature maintenance tank through the flash tank, maintained at 95°C-98°C for 1h-1.5h, then raised the temperature to 125°C-130°C through secondary spraying, maintained at 128°C for 5min, passed through the heat exchanger Cool the material to 62°C, put it into a pre-sterilized saccharification tank, add acid to adjust the pH to 4.4, add glucoamylase preparations in proportion, and keep saccharification at 60°C-62°C until the end of saccharification.

[0036] 2) Steam is introduced into the connecting pipelines, valves, pipeline pumps, filters and fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com