Device, system, and method for monitoring oil depot fuel leakage based on wireless sensing

A wireless sensing and monitoring device technology, applied in the field of oil and gas safety engineering, can solve problems such as wiring and maintenance safety inspection difficulties, exposed core wire explosion-proof treatment, and monitoring of no fuel leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation process.

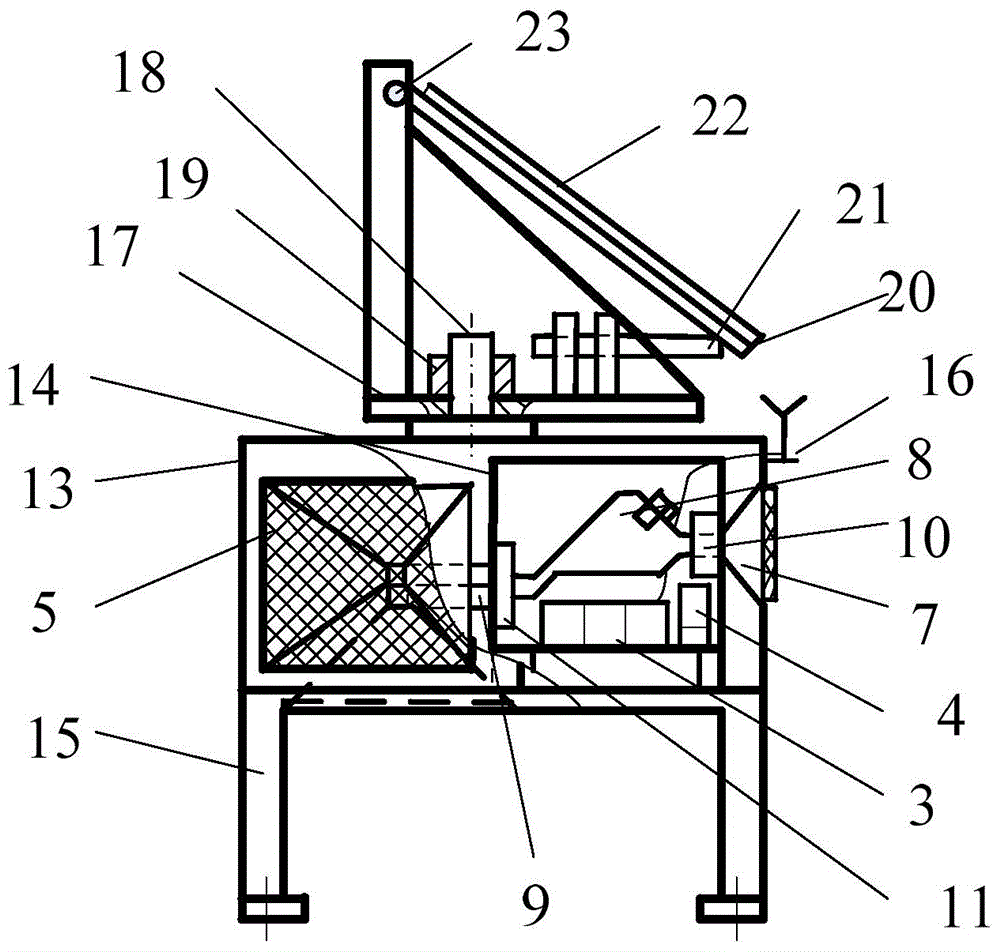

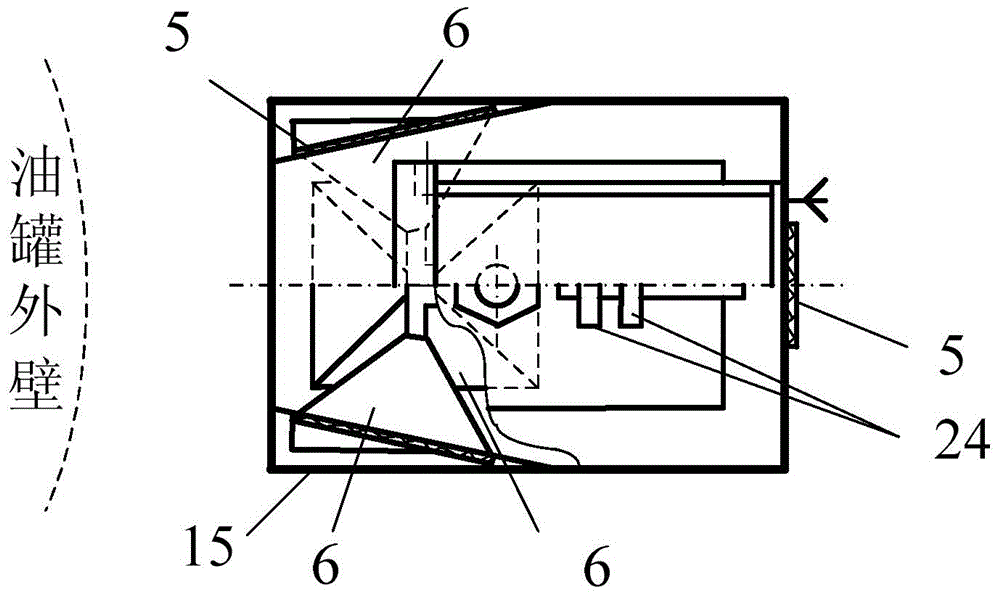

[0099] A fuel oil leakage monitoring device for an oil depot based on wireless sensing, comprising a bracket (15) and a main box fixed on the bracket;

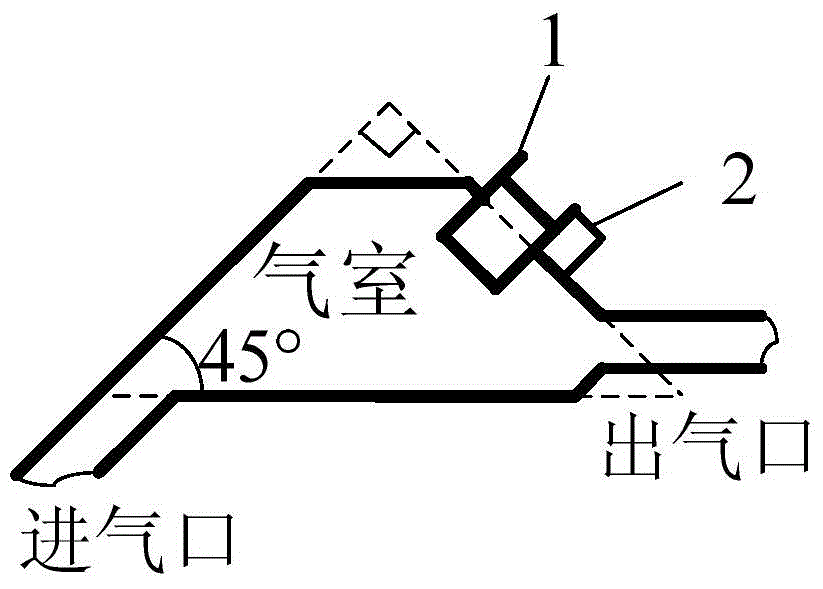

[0100] The main box is provided with a gas collecting device, a gas detection chamber (8), a main control board (3), a power module, an exhaust port (7), an air pump (10) and an electromagnetic air valve (11); The box body is also provided with an antenna (16);

[0101] The main control board, gas pump, electromagnetic gas valve, gas detection chamber and power module (excluding the solar cell part) [the above are live parts, used to isolate the live parts from the fuel and prevent explosions, and ensure the safety of the device and the application environment. Safety] are all placed in the cuboid, metal sealed box (14) fixed in the main box; the power supply module supplies power t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com