A Proportional Metering Oil Needle with Load Pressure Displacement Feedback

A technology of displacement feedback and metering oil needles, which is applied in the field of metering oil needles to achieve the effects of avoiding pressure instability, good dynamic characteristics, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

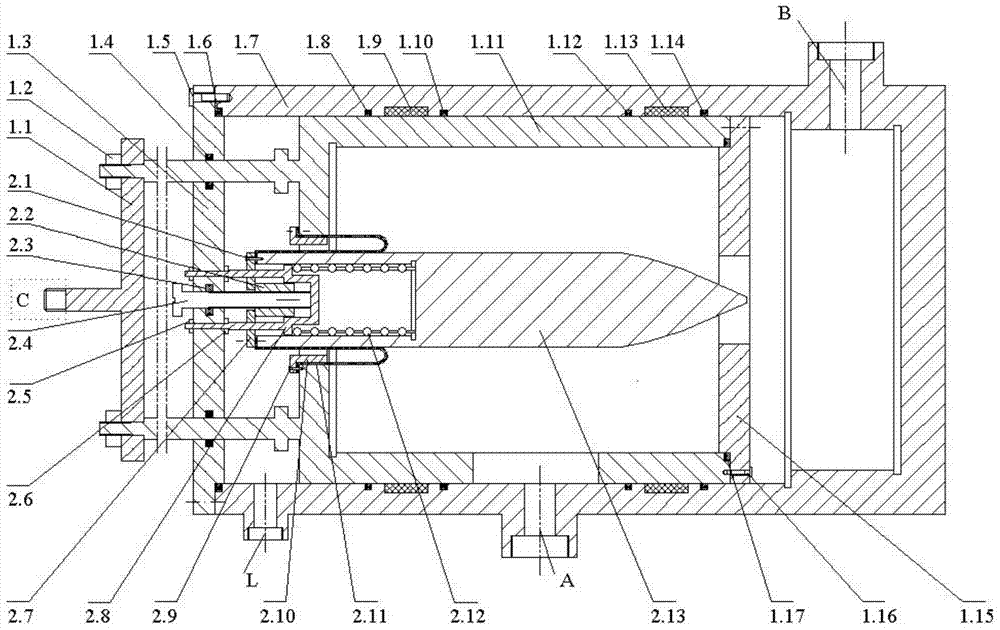

[0048] Such as figure 1 As shown, the present invention discloses a load pressure displacement feedback proportional metering oil needle, which includes a barrel assembly 1 and a pressure-sensing oil needle assembly 2 .

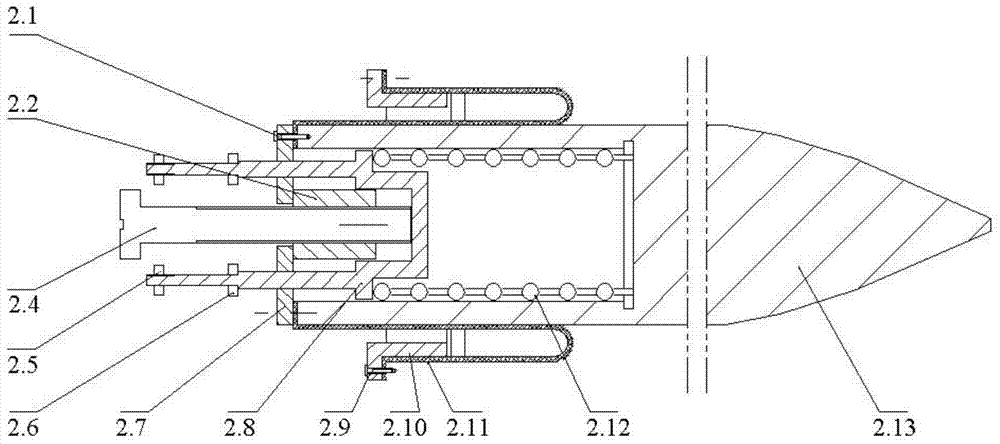

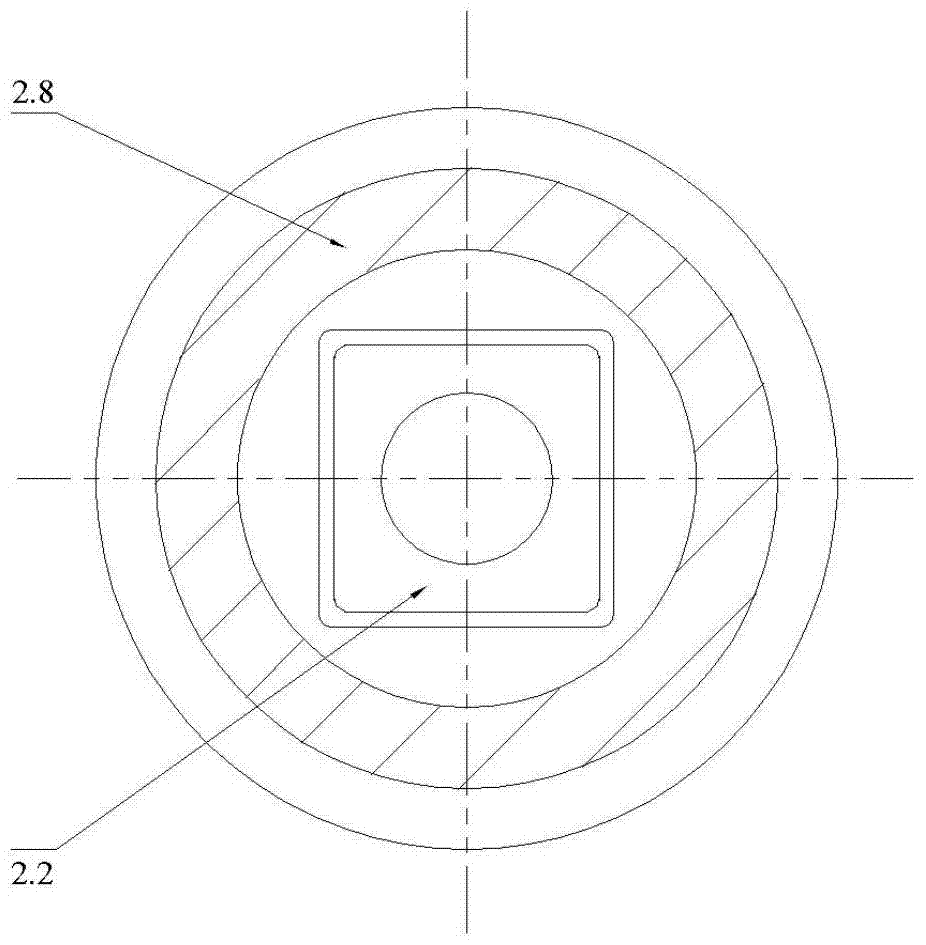

[0049] refer to figure 1 and combine figure 2 and image 3 As shown, cylinder assembly 1 includes coupling cover 1.1, lock nut 1.2, end cover 1.3, seal ring 1.4, coupling bolt 1.5, seal ring 1.6, outer cylinder 1.7, seal ring 1.8, wear ring 1.9, seal ring 1.10, inner cylinder body 1.11, sealing ring 1.12, wear ring 1.13, sealing ring 1.14, inner cylinder cover 1.15, connecting bolt 1.16, sealing ring 1.17, oil inlet A, oil outlet B, external control structure output port C, Drain port L.

[0050]The end cover 1.3 is fixed on the outer cylinder 1.7 by the connecting bolt 1.5, and there is a sealing ring 1.6 between the end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com