All-fiber valve leakage ultrasonic monitoring system

An ultrasonic monitoring, all-fiber technology, applied in the field of monitoring systems, can solve the problems of small frequency range of piezoelectric ultrasonic sensors, weak anti-interference ability, slow response speed, etc., to achieve improved dynamic range, long detection distance, and fast response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

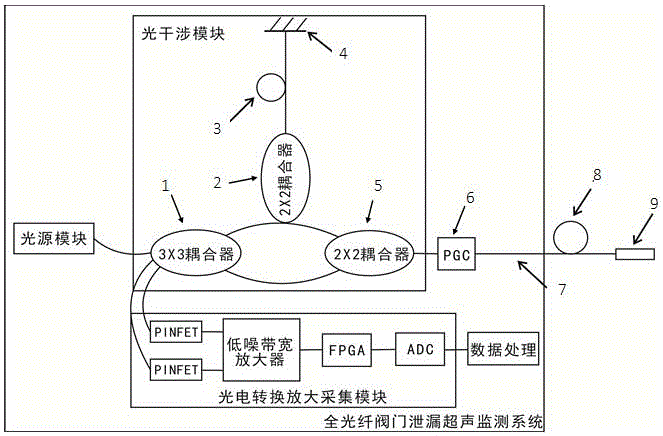

[0030] When the all-fiber valve leakage ultrasonic monitoring system is used for real-time leakage monitoring of the valve, the entire system is fixed at a position close to the valve, one end of the optical fiber sensor 8 is connected to the end reflection head 9, and the other end is connected to the ultrasonic monitoring host through the transmission optical cable 7 . The ultrasonic detection host includes an optical interference module, a light source module, a photoelectric conversion amplification acquisition module, a phase carrier modulation module (PGC), and a data processing module. Among them, the optical interference module includes a 3x3 coupler, two 2x2 couplers, delay fibers and reflectors, wherein the 3x3 coupler 1 is in phase with the light source module, photoelectric conversion amplification acquisition module and two 2x2 couplers (2, 5 ) connection, one of the 2x2 couplers 2 is also connected to the reflection head 4 through the delay fiber 3, and is also c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com