Preparation method of modified electrodes and use of modified electrodes in determination of free copper ions in feed additive copper lysine

A technology for modifying electrodes and electrodes, applied in the direction of electrochemical variables of materials, etc., can solve the problems of difficult to measure the content of free metal ions, difficult to separate trace elements, etc., and achieve the effects of high accuracy, simple preparation method, and simple detection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a modified electrode, comprising the steps of:

[0030] 1) Surface treatment of the bare glassy carbon electrode;

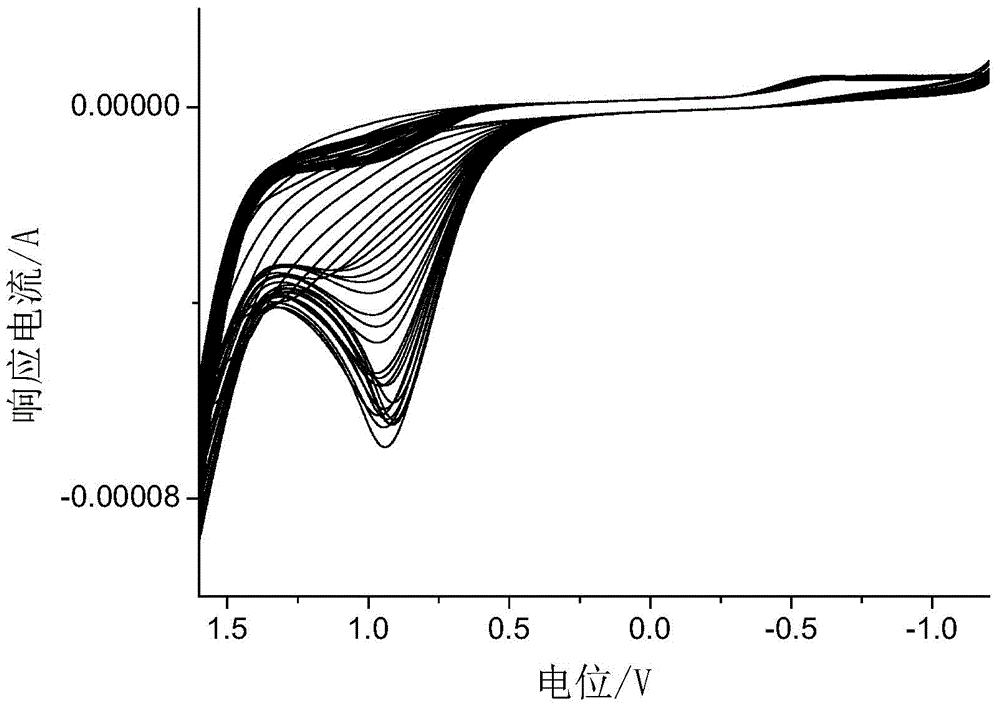

[0031] 2) Place the electrode, counter electrode, and reference electrode obtained in the previous step in the sulfuric acid solution for cyclic scanning until the voltammogram is stable, and then activate the electrode;

[0032] 3) The three electrodes are then placed in a solution containing cysteamine chelated metals, and cyclic scanning is performed to obtain the final modified electrode.

[0033] For the above method, preferably, in step 1), the surface treatment method is: grinding, polishing, cleaning, and drying; more preferably, it is: grinding the bare glassy carbon electrode (d=3mm) on metallographic sandpaper, followed by Al with particle size of 3μm, 0.5μm, 0.03μm 2 o 3 Polish the powder into a mirror surface; then use 2mol / LNaOH, (1+1)HNO 3 , 70vol% absolute ethanol and secondary water for ultrasonic cleaning, and t...

Embodiment 1

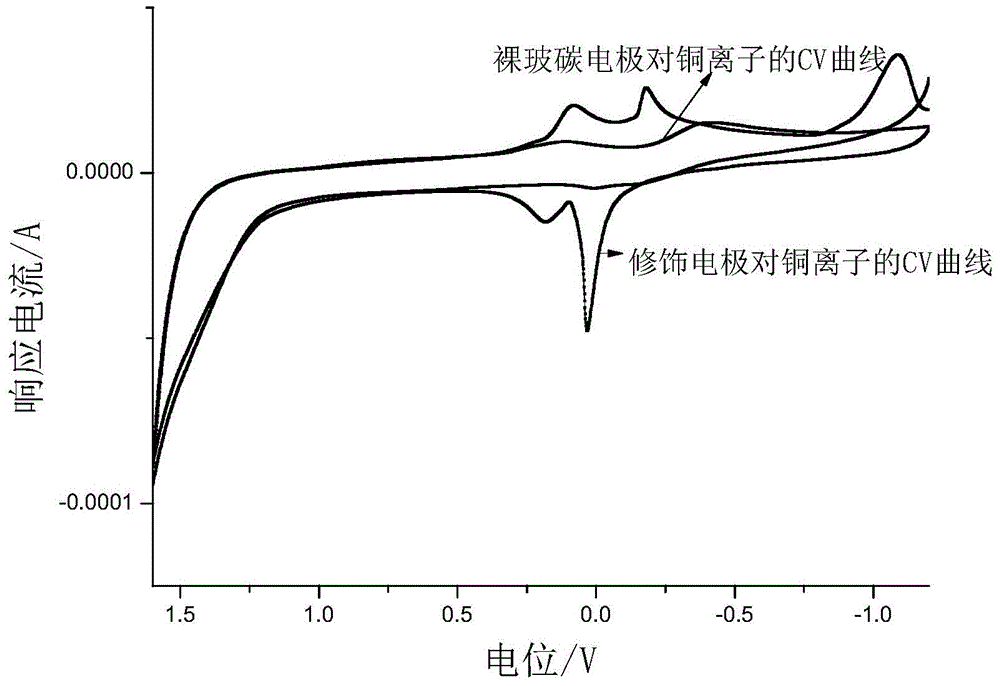

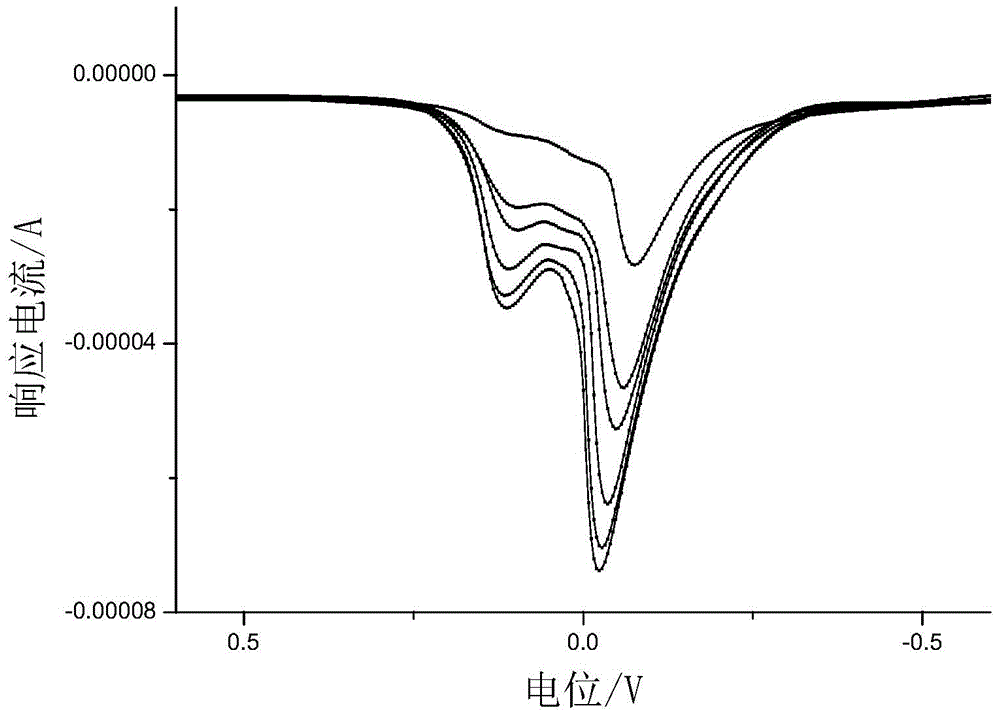

[0043] Grind the bare glassy carbon electrode (d=3mm) on metallographic sandpaper, and use Al 2 o 3 Powder polished to a mirror finish. Use 2mol / LNaOH, (1+1)HNO respectively 3 , 70% absolute ethanol and secondary water for ultrasonic cleaning, and the treated electrode was dried at room temperature. Put the cleaned bare glassy carbon electrode, counter electrode (1cm×1cm platinum sheet electrode) and reference electrode (saturated calomel electrode) into 0.5mol / LH 2 SO 4 Carry out cyclic scanning in the range of -1.2 ~ +1.6V until the voltammogram is stable, activate the electrode, and the scanning rate is 100mV / s. Then, put the three electrodes into a 6.0×10 -3 In the 0.1mol / L potassium chloride solution of mol / L3:2 cysteamine zinc solution, in the potential range of -1.2~+1.6V, 50mV / s cyclic scanning for 30 circles, the CS-Zn / GCE modified electrode was prepared .

[0044] Representation example:

[0045] Preparation of 3:2 zinc cysteamine / GCE modified electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com