Medium and small power LD parallelly pumped high-power green laser

A medium and small power, laser technology, applied in the field of lasers, can solve the problems of matching coupling characteristics between rods, affecting the stability of the laser system, and instability of the resonator cavity, achieving high thermal stability, reducing high thermal effects, and reducing pump power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

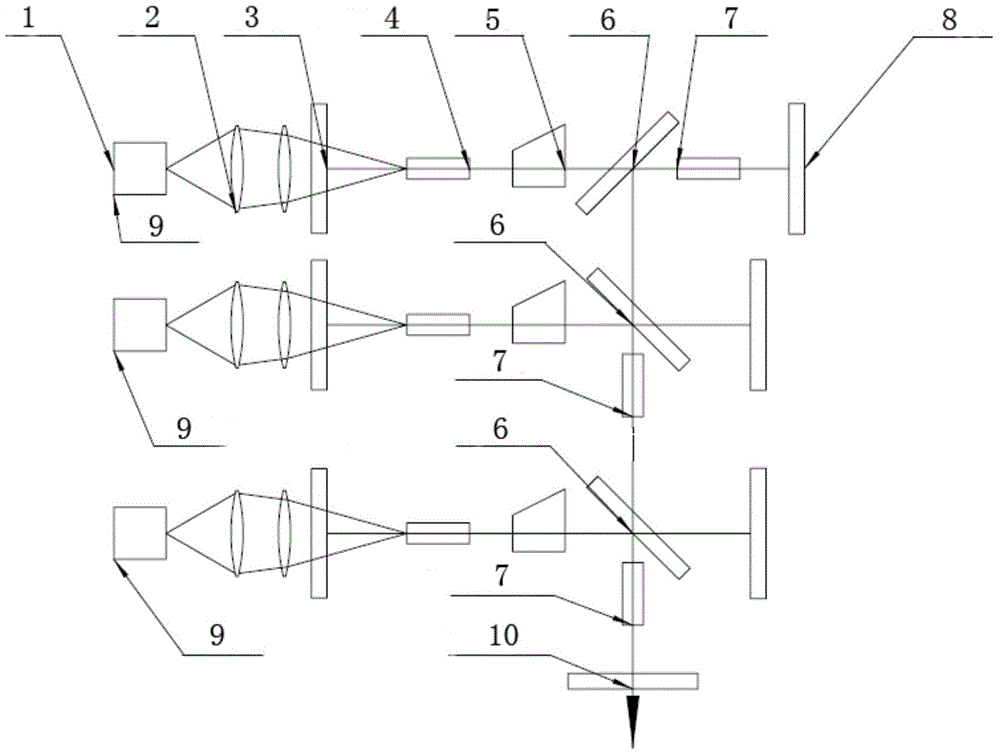

[0025] Please refer to figure 1 The said low- and medium-power LD parallel-pumped high-power green laser includes three frequency-doubled crystals 7, three end-pumped lasers 9 and a resonant cavity. The three end-pumped lasers 9 are arranged in parallel, the optical axes of the three end-pumped lasers 9 are parallel, and two of the three frequency doubling crystals 7 are located in the resonant cavity to form a frequency doubling resonant cavity. One end of the resonant cavity is the second output mirror 10. Each end pump laser 9 includes an end pump device composed of a pump source 1, a coupling mirror 2 and a laser crystal 4, a sub-resonator composed of a first total mirror 3 and a second total mirror 8, and a The Q switch 5 used to modulate the pulsed laser and the first output mirror 6 used to reflect and output the pulsed laser in the resonant cavity form an angle of 45° with the optical axis of the end pump laser 9.

[0026] The first output mirror 6 of the two end-pumped ...

Embodiment 2

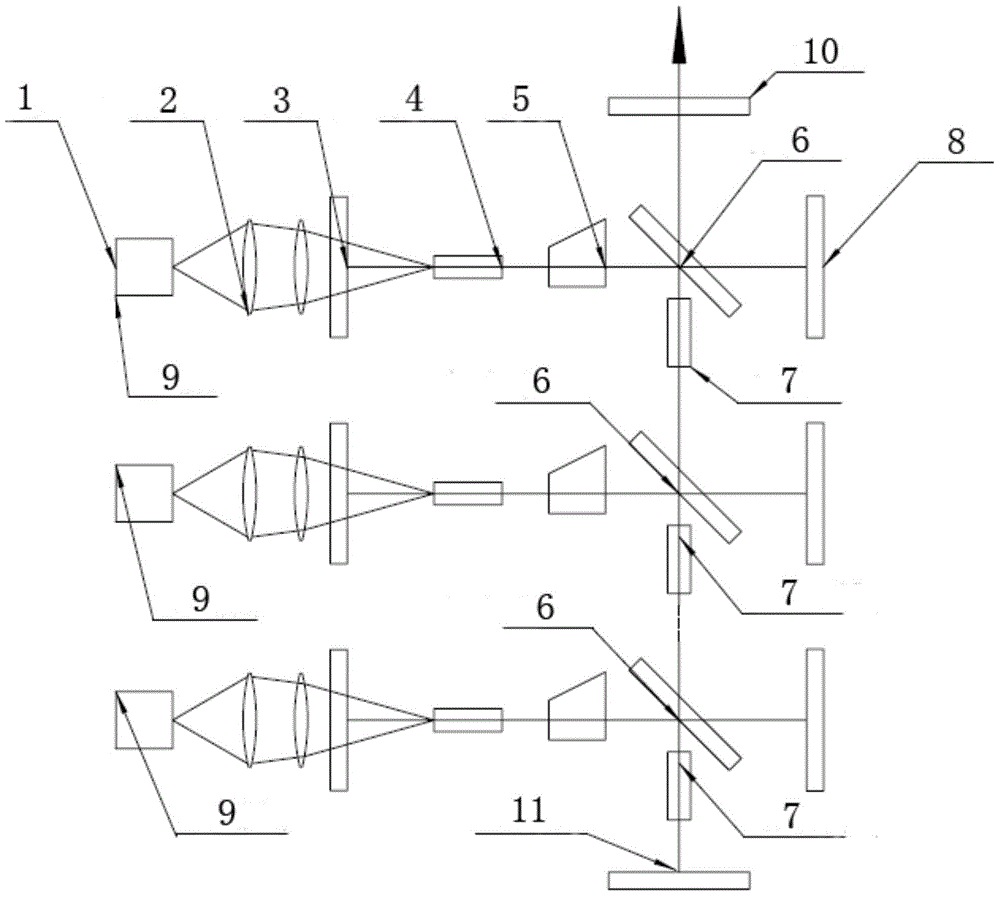

[0032] Please refer to figure 2 The said low- and medium-power LD parallel-pumped high-power green laser includes three frequency-doubled crystals 7, three end-pumped lasers 9 and a resonant cavity. One end of the resonant cavity is the second output mirror 10, and the other end is the third total mirror 11, and the resonant cavity is a straight cavity. Three end-pumped lasers 9 are arranged in parallel, the optical axes of the three end-pumped lasers 9 are parallel, and the three frequency-doubling crystals 7 are all located in the resonant cavity to form a frequency-doubling resonant cavity, the frequency-doubling resonator and each end-pumped laser The optical axis of 9 is vertical. Each end pump laser 9 includes an end pump device composed of a pump source 1, a coupling mirror 2 and a laser crystal 4, a sub-resonator composed of a first total mirror 3 and a second total mirror 8, and a The Q switch 5 used to modulate the pulse laser in the resonator and the first output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com