Polybutadiene-modified polymer polyol, foam prepared from polybutadiene-modified polymer polyol, and method for preparing same

A technology of polybutadiene and polyol, applied in the field of polymer polyol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

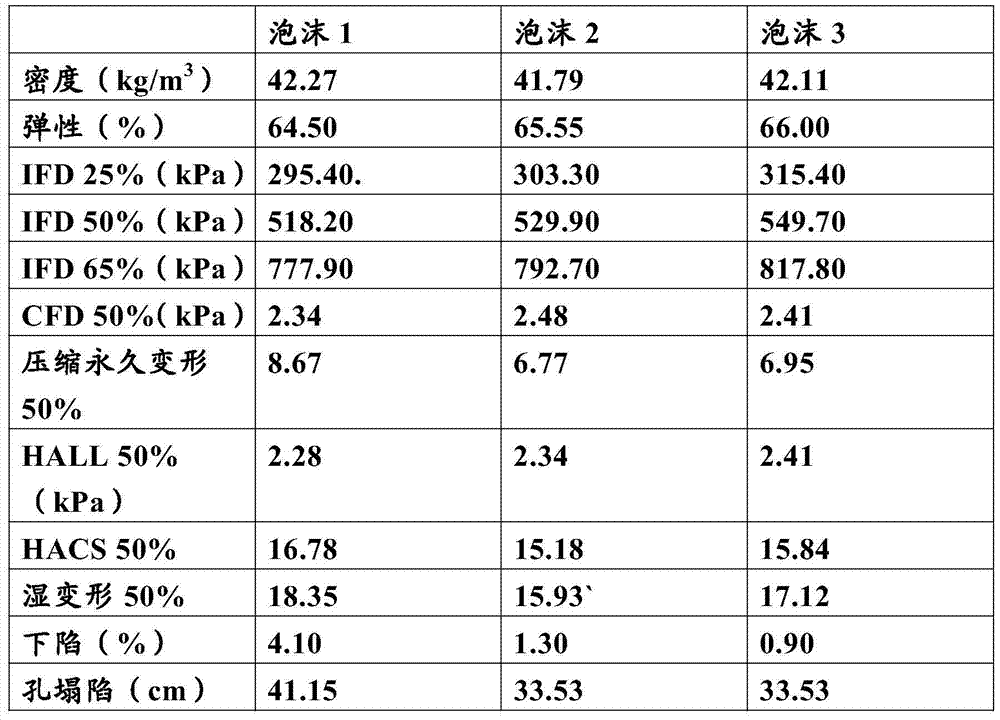

Examples

Embodiment

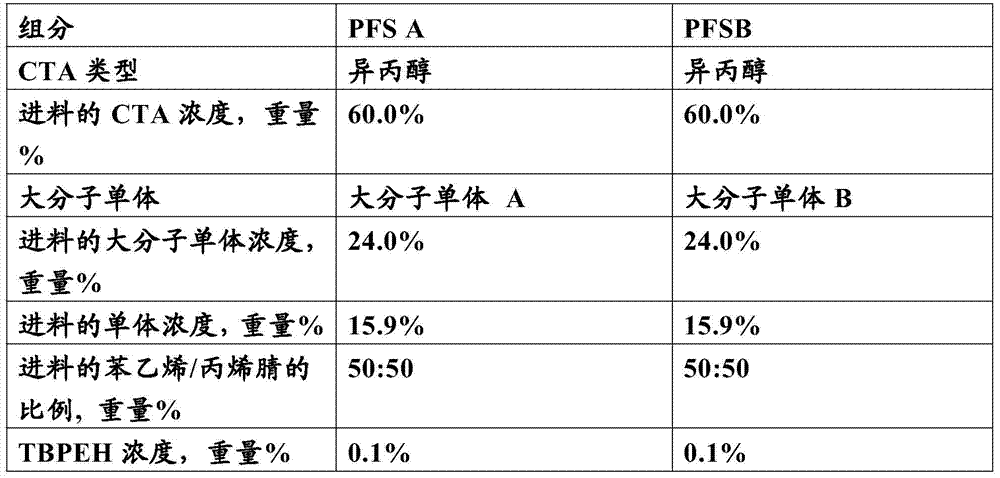

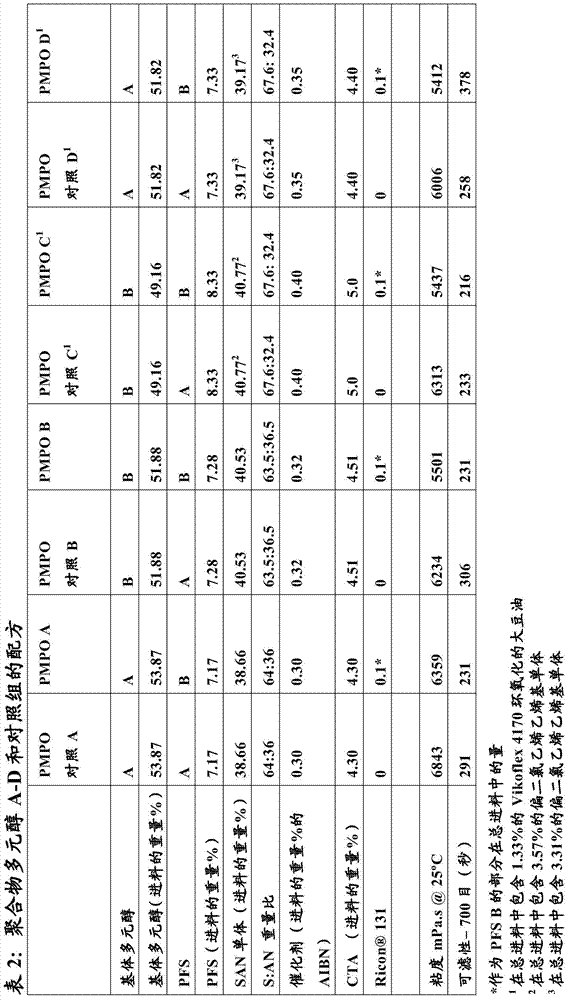

[0112] The following components were used in the examples.

[0113] Polyol A : Propylene oxide adduct of sorbitol, containing 16% ethylene oxide capping, hydroxyl value 28 and viscosity 1700mPa.s

[0114] Base Polyol A : Propylene oxide adduct of sorbitol and glycerol, containing 17% ethylene oxide capping, hydroxyl value 32 and viscosity 1100mPa.s

[0115] Base Polyol B : Propylene oxide adduct of glycerol, containing 20% ethylene oxide capping, hydroxyl value 36 and viscosity 820mPa.s

[0116] CTAs : Isopropanol, chain transfer agent

[0117] SAN : Styrene: Acrylonitrile

[0118] TMI : Isopropenyl dimethyl benzyl isocyanate (unsaturated aliphatic isocyanate), sold by Cytec Industries sell

[0119] MDI : monomeric MDI, comprising about 42% by weight of the 4,4'-isomer of MDI, about 57% by weight of the 2,4'-isomer of MDI and the balance being the 2,2'-isomer of MDI body

[0120] TBPEH : tert-butyl peroxy-2-ethylhexanoate

[0121] AIBN : 2,2'-Azobis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com