Production method for selenium-enriched ganoderma mycelium

A technology of Ganoderma lucidum mycelium and production method, which is applied in the fields of botanical equipment and methods, fertilizer mixtures, horticulture, etc., can solve the problems of toxicity, unfavorable absorption, low content, etc. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

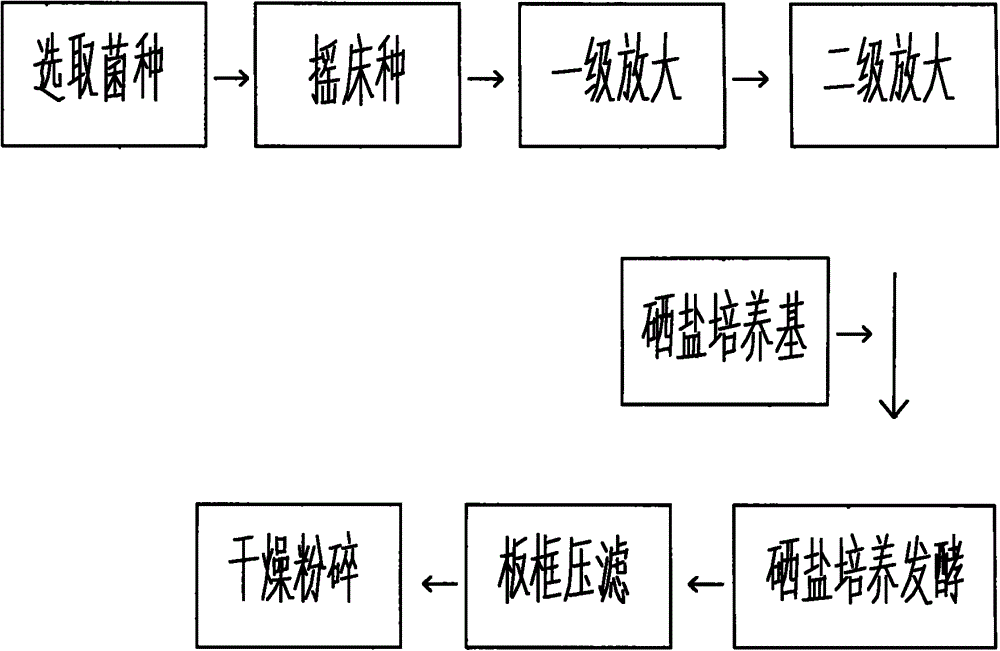

Method used

Image

Examples

Embodiment 1

[0031] Other steps are unchanged, as mentioned above, only the composition of the selenium salt medium in above-mentioned steps 5) is:

[0032] 2% corn flour, 1% soybean flour, 1% glucose, 0.1% potassium dihydrogen phosphate, 0.05% sodium selenite, 0.05% magnesium sulfate, 150ppm vitamin B, and the balance is deionized water. The content of selenium element in the selenium-enriched ganoderma lucidum mycelium product is 75ppm.

Embodiment 2

[0034] Other steps are as embodiment 1, just change the composition of the selenium salt culture medium in above-mentioned step 5) into: corn flour 5%, soybean flour 2%, glucose 3%, potassium dihydrogen phosphate 0.5%, sodium selenite 0.1 %, magnesium sulfate 0.1%, vitamin B1100ppm, and the balance is deionized water. The content of selenium element in the selenium-enriched ganoderma lucidum mycelium product is 89ppm.

Embodiment 3

[0036] Other steps are as embodiment 1, just change the composition of the selenium salt culture medium in above-mentioned step 5) into: corn flour 3.5%, soybean flour 1.5%, glucose 2%, potassium dihydrogen phosphate 0.3%, sodium selenite 0.07% %, magnesium sulfate 0.07%, vitamin B175ppm, and the balance is deionized water. The content of selenium element in the selenium-enriched ganoderma lucidum mycelium product is 81ppm.

[0037] The method for measuring the content of selenium in the above examples is a colorimetric spectrophotometer method, and the determination is carried out according to the national standard GB / T5009.93-2010.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com