Method and system for treating fly ash in manner combining mechanochemistry and washing, with characteristics of high efficiency, low cost and zero harm

A mechanochemical, low-cost technology, applied in the direction of solid waste removal, recycling technology, electronic waste recycling, etc., can solve the problem of poor long-term stability of calcium silicate colloid, potential threat of increasing fly ash environment, lack of resources In order to achieve the effect of low disposal cost, remarkable disposal effect, low equipment investment and operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

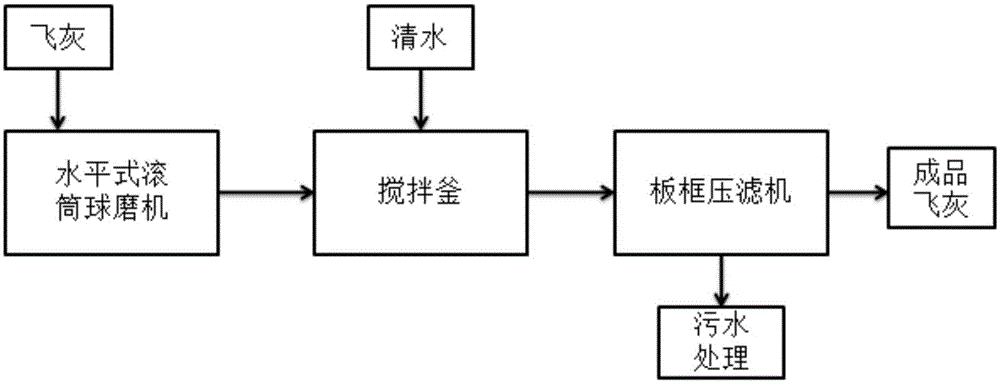

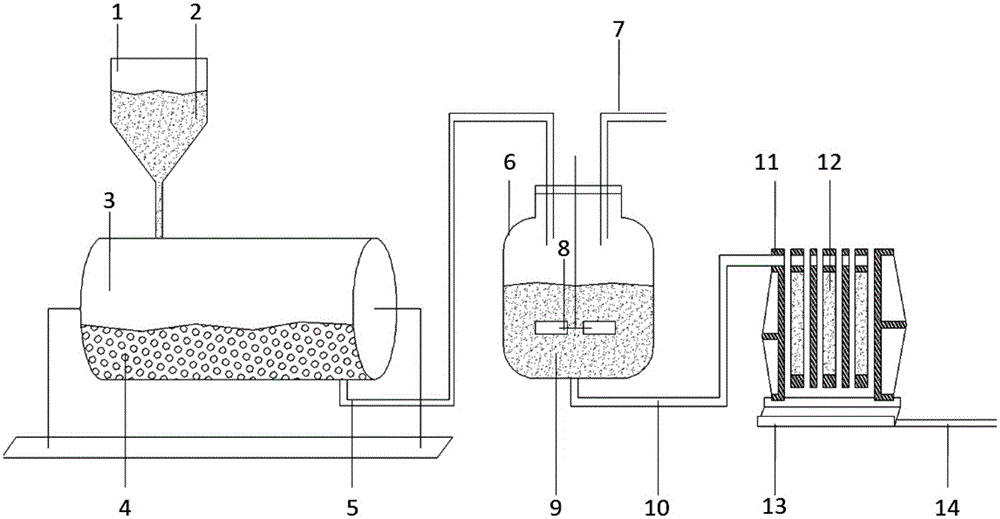

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0032] The high-efficiency, low-cost and harmless disposal system for mechanochemically combined with water-washed fly ash of the present invention includes a feeding bin 1 for storing fly ash to be disposed, a horizontal drum type ball mill 3, a stirring tank 6 and a plate-and-frame filter press 11. The bottom of the feeding bin 1 is connected to the feed inlet on the upper part of the horizontal roller ball mill 3. The horizontal roller ball mill 3 has an airtight cylinder in which a plurality of stainless steel grinding balls 4 are placed; one end of the discharge pipe 5 Connected to the bottom of the horizontal drum type ball mill 3, the other end is connected to the upper part of the stirring tank 6; the upper part of the stirring tank 6 is also connected to the water inlet pipe 7, and the bottom is connected to the outlet pipe 10; To the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com