Cemented carbide/INVAR/steel laser beam welding assembly and manufacturing method thereof

A cemented carbide and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy cracking and incomplete penetration of welded joints, and achieve the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail and completely below in conjunction with the embodiments and accompanying drawings.

[0027] After surface treatment, the material to be welded is fixed on the operating platform of the external axis positioner according to the assembly requirements; the process parameters are input into the robot programming controller to perform automatic welding; after the welding is completed, the microscopic forming analysis of the sample is carried out.

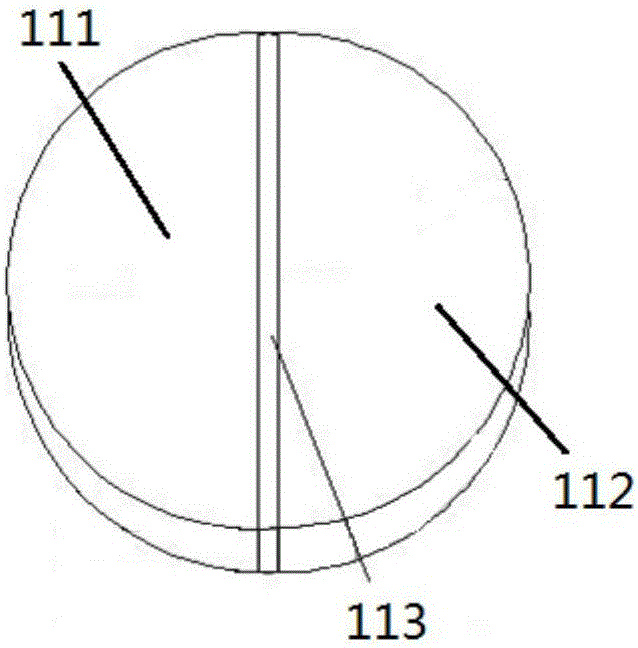

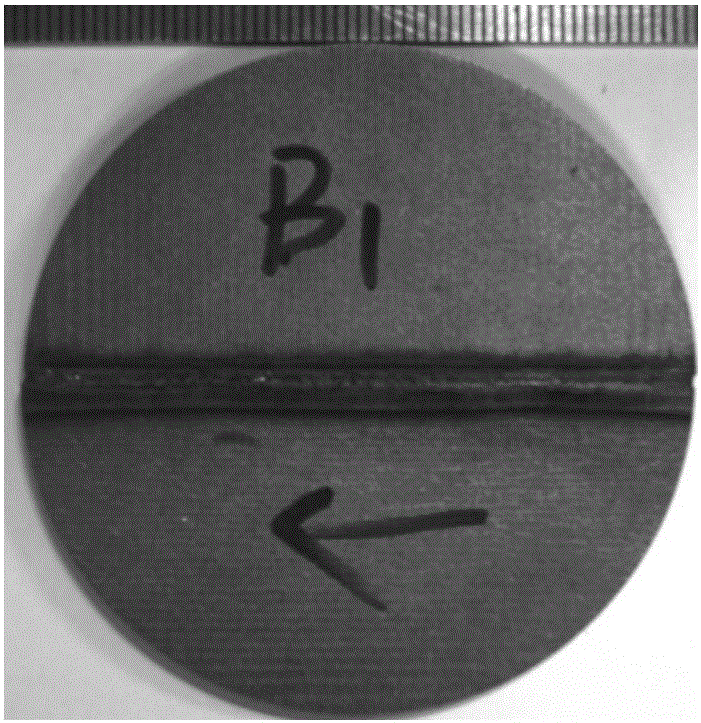

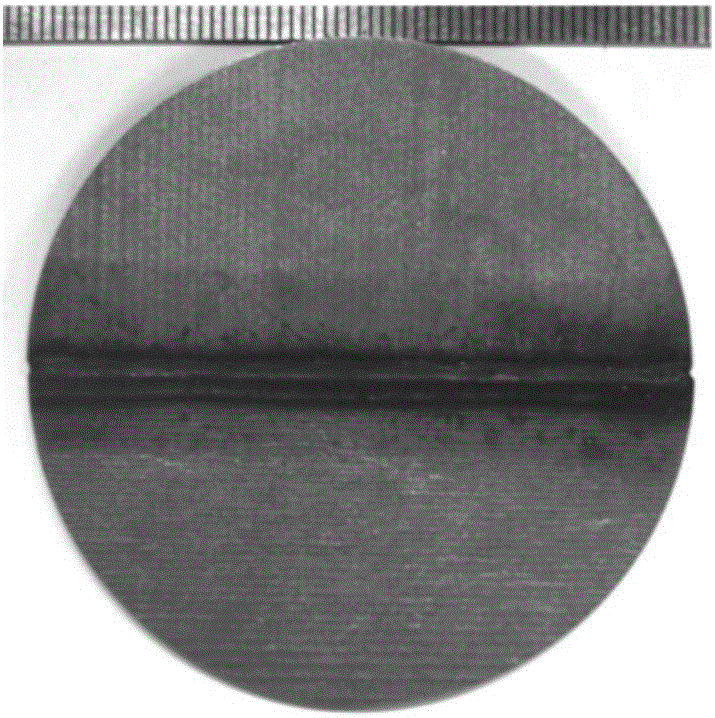

[0028] The laser welding schematic diagram of the present invention is as figure 1 As shown, the materials to be welded are YG20 cemented carbide 111 and 45# steel 112, size: φ58×3mm semicircle, the surface is desmeared, cleaned with acetone or alcohol for later use; filling material: Invar alloy containing 42% Ni 113, a long strip with a size of 58×0.5×3mm; protective gas: pure argon. IPG-YLS-5000W ytterbium-doped multimode fiber laser is used as the heat source, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com