Preparation method of sulfydryl-grafted and photocatalyst-loaded high silica glass fiber for soil pollution remediation

A technology of high-silica glass fiber and photocatalyst, which is applied in the field of preparation of high-silica glass fiber to achieve broad development prospects, increase filtration efficiency, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

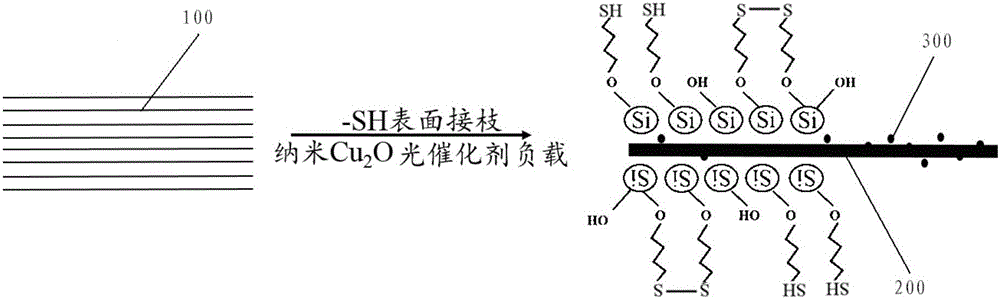

[0034] This example provides a preparation method of mercapto-grafted and photocatalyst-loaded high-silica glass fibers for soil pollution remediation, including the preparation method of mercapto-grafted high-silica glass fibers and photocatalyst-loaded mercapto-grafted high The preparation method of silica glass fiber, wherein:

[0035] The preparation method of the mercapto-grafted high-silica glass fiber comprises the following steps: S1: Weigh 100ml of ethanol reagent and dissolve it in 500ml of deionized water; S2: add high-silica glass with a weight of 50g and a length of 30cm to the above solvent Ultrasound for fiber filaments at 1kHz for 10min; S3: Weigh 10g of mercaptopropyltrimethoxysilane and dissolve it in 5ml of toluene for later use; S4: Add mercaptopropyltrimethoxysilane to the glass fiber filaments immersed in the organic solution , and placed on a constant temperature shaker at a temperature of 50°C for 2 hours; S5: take it out after the reaction is completed...

Embodiment 2

[0038] This example provides a preparation method of mercapto-grafted and photocatalyst-loaded high-silica glass fibers for soil pollution remediation, including the preparation method of mercapto-grafted high-silica glass fibers and photocatalyst-loaded mercapto-grafted high The preparation method of silica glass fiber, wherein:

[0039] The preparation method of the mercapto-grafted high-silica glass fiber comprises the following steps: S1: Weigh 150ml of ethanol reagent and dissolve it in 800ml of deionized water; S2: add high-silica glass with a weight of 80g and a length of 45cm to the above solvent Ultrasound for fiber filaments at 60kHz for 15min; S3: Weigh 15g of mercaptopropyltrimethoxysilane and dissolve it in 8ml of toluene for later use; S4: Add mercaptopropyltrimethoxysilane to the glass fiber filaments immersed in the organic solution , and placed on a constant temperature shaker at a temperature of 65°C for 7 hours; S5: take it out after the reaction is complete...

Embodiment 3

[0042] This example provides a preparation method of mercapto-grafted and photocatalyst-loaded high-silica glass fibers for soil pollution remediation, including the preparation method of mercapto-grafted high-silica glass fibers and photocatalyst-loaded mercapto-grafted high The preparation method of silica glass fiber, wherein:

[0043] The preparation method of the mercapto-grafted high-silica glass fiber comprises the following steps: S1: Weigh 200ml of ethanol reagent and dissolve it in 1000ml of deionized water; S2: add high-silica glass with a weight of 100g and a length of 60cm to the above solvent Fiber filaments, ultrasonically ultrasonicated at 120kHz for 20min; S3: Weigh 20g of mercaptopropyltrimethoxysilane and dissolve it in 10ml of toluene for later use; S4: Add mercaptopropyltrimethoxysilane to the glass fiber filaments immersed in the organic solution , and placed on a constant temperature shaker at a temperature of 80°C for 12 hours; S5: Take it out after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com