Process for using yellow vinasse to produce arrack

A technology for yellow rice wine lees and liquor, which is applied in the preparation of alcoholic beverages and other directions, can solve the problems of low yield of glutinous liquor and other problems, and achieve the effects of improving the economic benefits of enterprises, improving yield and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

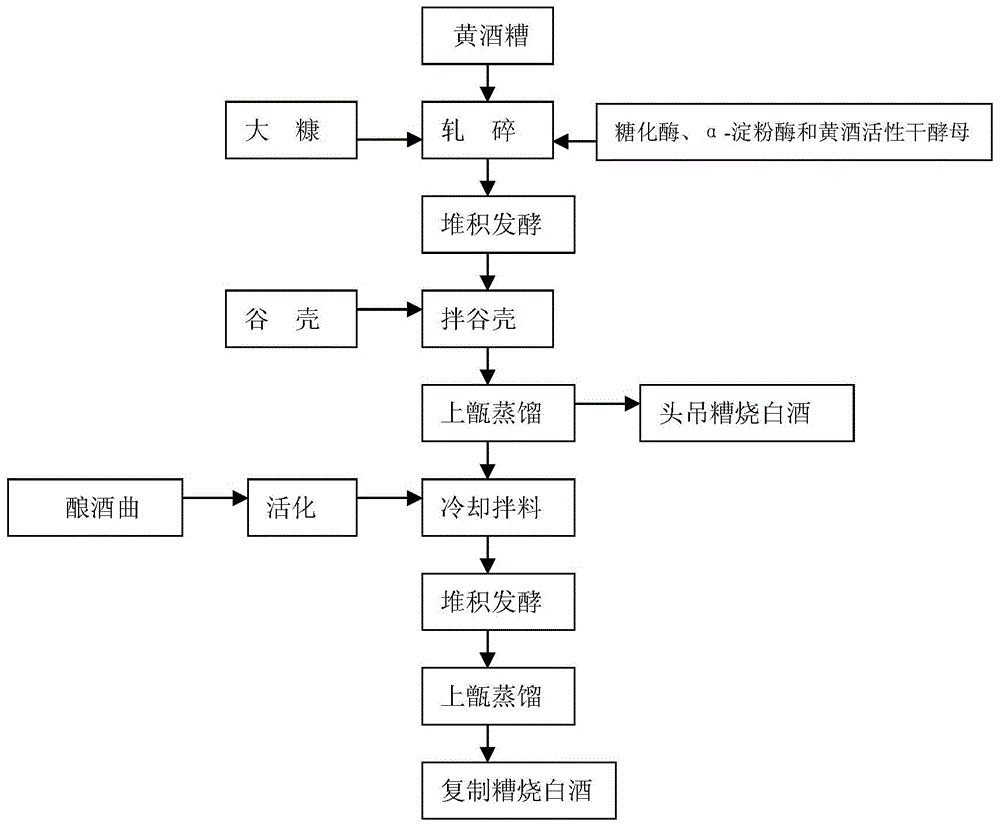

[0027] combine figure 1 Shown, a kind of technique of yellow rice distiller's grains producing distiller's grains burns liquor, comprises the following steps:

[0028] (1) Crushing: Add rice bran, glucoamylase (50000U), α-amylase (4000U) and rice wine active dry yeast to rice wine grains, and crush them into loose and fine grains with a crusher; among them, rice wine grains, rice wine grains The mass ratio between bran, glucoamylase, α-amylase and rice wine active dry yeast is 100:6:0.1:0.1:0.1;

[0029] (2) Accumulation fermentation: The crushed yellow rice wine grains are piled up and fermented in a sealed manner. The accumulation height of the yellow rice wine grains is 0.8 meters. The plastic film is used to cover the surface of the grains, and the four sides are sealed with large bran for fermentation. The sealed fermentation time is 15 days. ;

[0030] (3) Distillation: take out the distiller's grains, mix them into the chaff, the mass ratio between the distiller's...

Embodiment 2

[0035] combine figure 1 Shown, a kind of technique of yellow rice distiller's grains producing distiller's grains burns liquor, comprises the following steps:

[0036] (1) Crushing: Add rice bran, glucoamylase (50000U), α-amylase (4000U) and rice wine active dry yeast to rice wine grains, and crush them into loose and fine grains with a crusher; among them, rice wine grains, rice wine grains The mass ratio between bran, glucoamylase, α-amylase and rice wine active dry yeast is 100:7:0.15:0.15:0.15;

[0037] (2) Accumulation fermentation: The crushed yellow rice wine grains are piled up and sealed for fermentation. The height of the piled rice wine grains is 1 meter. The surface of the grains is covered with a plastic film, and the four sides are sealed with large bran for fermentation. The sealed fermentation time is 16 days. ;

[0038] (3) Distillation: take out the distiller's grains, mix them into the chaff, the mass ratio between the distiller's grains and the chaff ...

Embodiment 3

[0043] combine figure 1 Shown, a kind of technique of yellow rice distiller's grains producing distiller's grains burns liquor, comprises the following steps:

[0044] (1) Crushing: Add rice bran, glucoamylase (50000U), α-amylase (4000U) and rice wine active dry yeast to rice wine grains, and crush them into loose and fine grains with a crusher; among them, rice wine grains, rice wine grains The mass ratio between bran, glucoamylase, α-amylase and rice wine active dry yeast is 100:8:0.2:0.2:0.15;

[0045] (2) Accumulated fermentation: The crushed yellow rice wine grains are piled up and fermented in a sealed manner. The piled height of the yellow rice wine grains is 1.2 meters. The plastic film is used to cover the surface of the grains, and the four sides are sealed with bran for fermentation. The sealed fermentation time is 18 days. ;

[0046] (3) Distillation: Take out the distiller's grains, mix them into the chaff, the mass ratio between the distiller's grains and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com