Electro-magnetic induction internal thermal type metallic magnesium vacuum reduction furnace

An electromagnetic induction and internal heating technology, applied in the direction of electric furnace heating, furnace, furnace components, etc., can solve the problems of connection electrode burnout, difficulty in loading and unloading materials, low strength, etc., and achieve low heat loss, small heat loss, and rapid heat conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

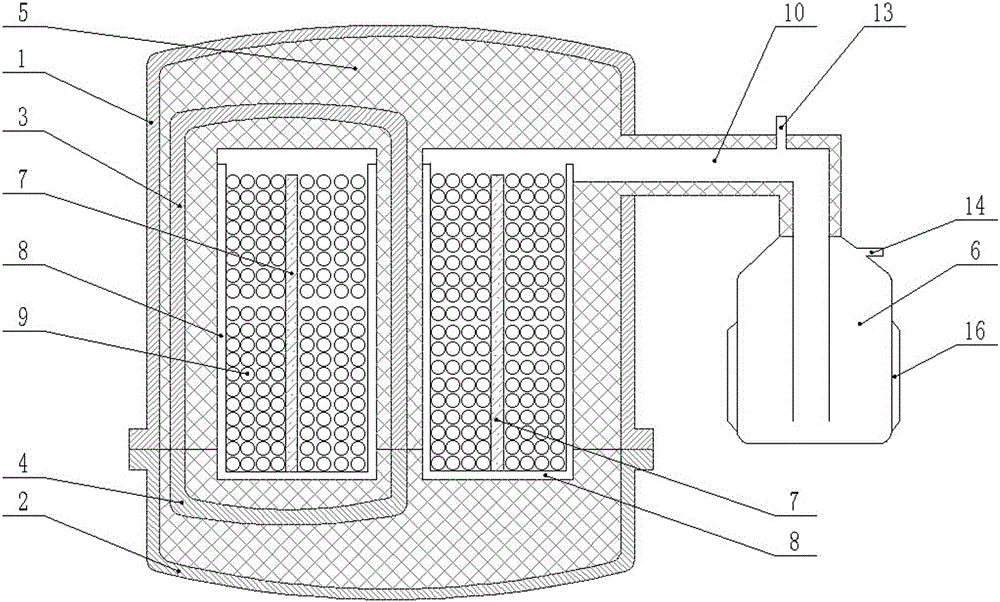

[0036] An electromagnetic induction internal heating type metal magnesium vacuum reduction furnace includes a vertical furnace body and two furnace chambers, which are respectively a reduction reaction chamber and a crystallization chamber.

[0037] Such as figure 1 As shown, the furnace body is composed of an upper furnace shell 1 and a lower furnace cover 2, and the upper furnace shell 1 and the lower furnace cover 2 are connected by flanges.

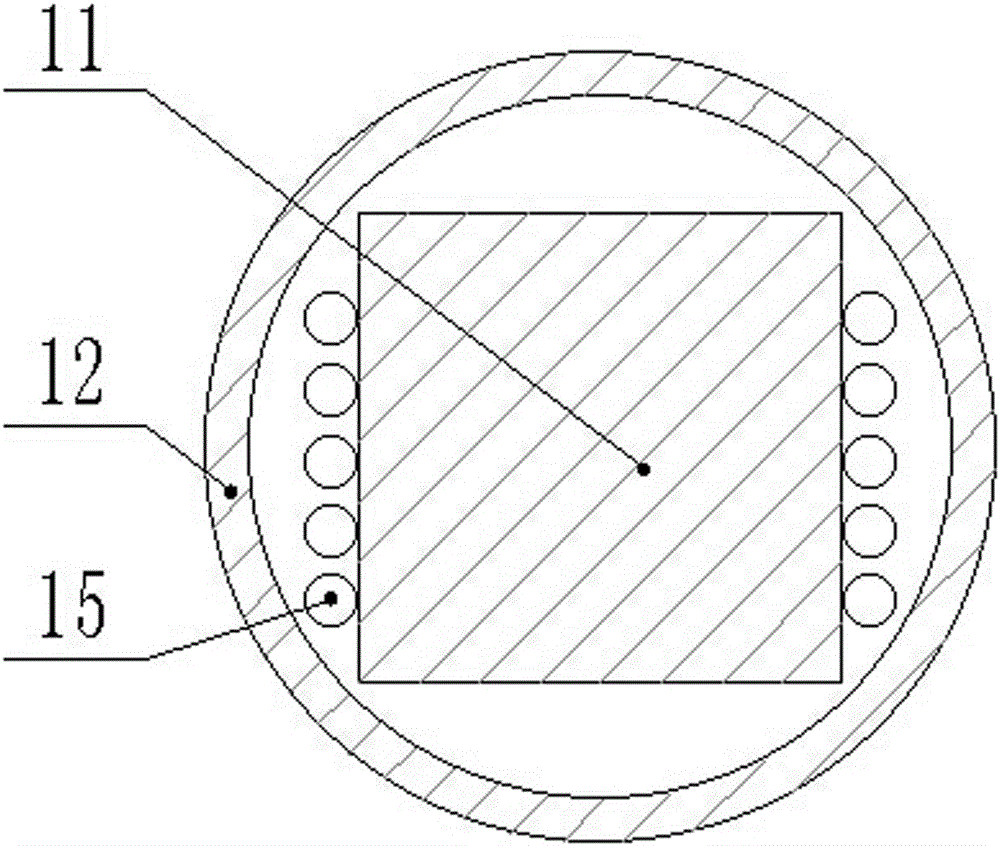

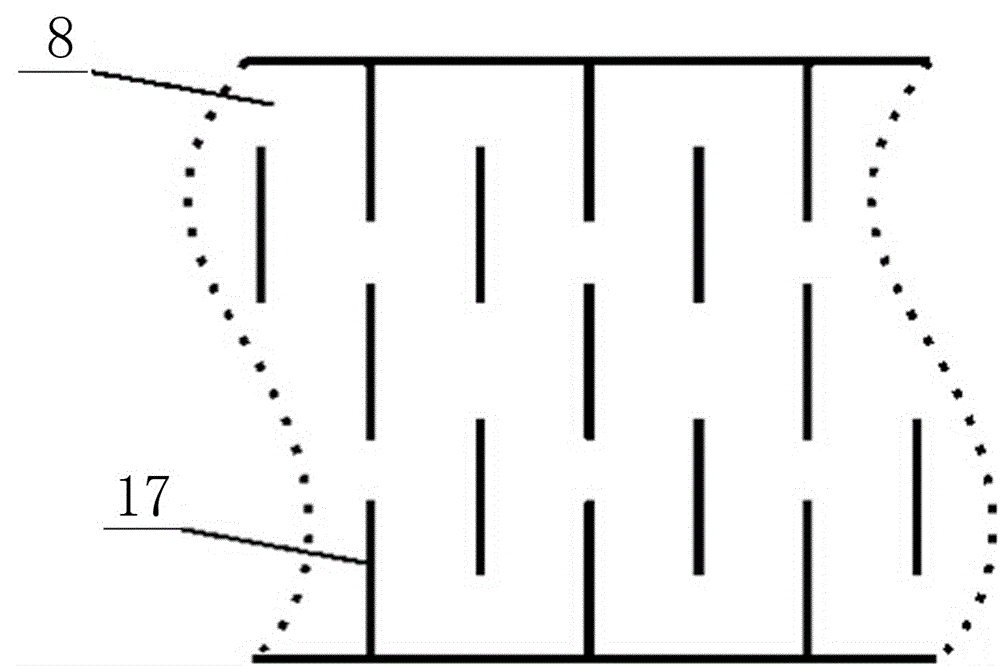

[0038] Such as figure 1 As shown, the furnace body is provided with a material basket 8 , and the central part of the material basket 8 is provided with a central channel passing through the bottom surface of the material basket 8 . According to the different sizes of the material basket, one or more heating tubes 7 are arranged concentrically in the material basket 8 . There is sufficient heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com