A kind of pickling additive and preparation method thereof

A technology for pickling additives and reaction tanks, which is applied in the field of metal surface treatment, can solve the problems of reducing the speed of rust removal, volatile hydrochloric acid, and fast corrosion of the substrate, and achieves the effects of reducing dosage, reducing air pollution and weakening the effect of corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

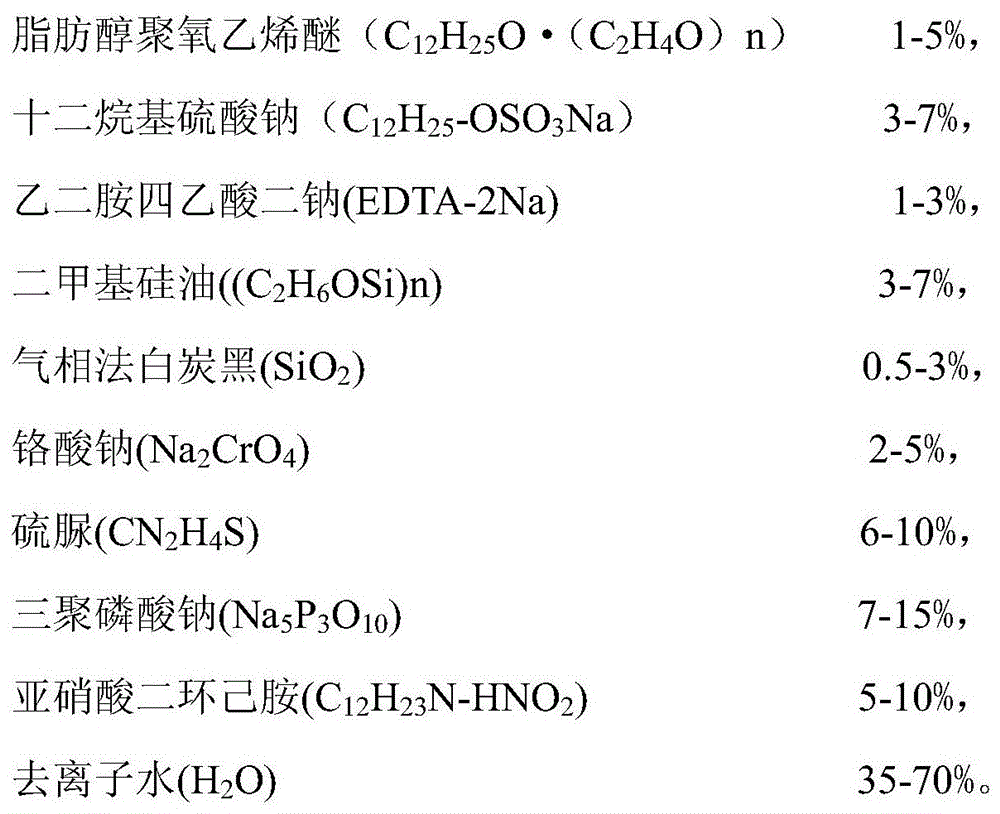

[0034] A novel pickling additive comprising the following components by weight ratio:

[0035]

[0036] The preparation method of pickling additive comprises the following steps:

[0037] (1) Add the required deionized water into the stainless steel reaction tank and heat to 50°C;

[0038] (2), add in the stainless steel reaction tank after fatty alcohol polyoxyethylene ether is dissolved;

[0039] (3), add in the stainless steel reaction tank after dissolving dimethyl silicone oil and fumed silica;

[0040] (4), after dissolving sodium chromate, thiourea, sodium tripolyphosphate, and dicyclohexylamine nitrite respectively, add in the stainless steel reaction tank in sequence;

[0041] (5) Add disodium edetate into the reaction tank after completely dissolving it in hot water at 50°C;

[0042] (6), sodium lauryl sulfate is added in the reaction tank after being dissolved in hot water at 100°C;

[0043] (7) Start the agitator and stir for 10 minutes before leaving the ta...

Embodiment 2

[0045] A novel pickling additive is characterized in that it comprises the following components by weight ratio:

[0046]

[0047] The preparation method of pickling additive comprises the following steps:

[0048] (1) Add the required deionized water into the stainless steel reaction tank and heat to 40°C;

[0049] (2), add in the stainless steel reaction tank after fatty alcohol polyoxyethylene ether is dissolved;

[0050] (3), add in the stainless steel reaction tank after dissolving dimethyl silicone oil and fumed silica;

[0051] (4), after dissolving sodium chromate, thiourea, sodium tripolyphosphate, and dicyclohexylamine nitrite respectively, add in the stainless steel reaction tank in sequence;

[0052] (5) Add disodium edetate into the reaction tank after completely dissolving it in hot water at 50°C;

[0053] (6), sodium lauryl sulfate is added in the reaction tank after being dissolved in hot water of 95°C;

[0054] (7) Start the agitator and stir for 10 min...

Embodiment 3

[0056] A novel pickling additive is characterized in that it comprises the following components by weight ratio:

[0057]

[0058] The preparation method of pickling additive comprises the following steps:

[0059] (1) Add the required deionized water into the stainless steel reaction tank and heat to 50°C;

[0060] (2), add in the stainless steel reaction tank after fatty alcohol polyoxyethylene ether is dissolved;

[0061] (3), add in the stainless steel reaction tank after dissolving dimethyl silicone oil and fumed silica;

[0062] (4), after dissolving sodium chromate, thiourea, sodium tripolyphosphate, and dicyclohexylamine nitrite respectively, add in the stainless steel reaction tank in sequence;

[0063] (5) Add disodium edetate into the reaction tank after completely dissolving it in hot water at 50°C;

[0064] (6), sodium lauryl sulfate is added in the reaction tank after being dissolved in hot water at 100°C;

[0065] (7) Start the agitator and stir for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com