Patents

Literature

30 results about "Dicyclohexylamine nitrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

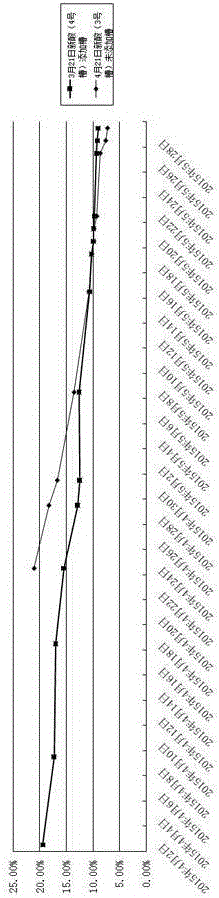

Application Year

Inventor

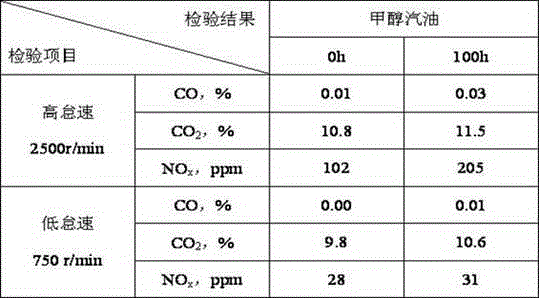

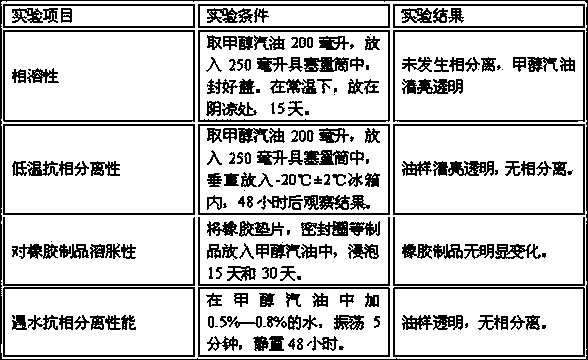

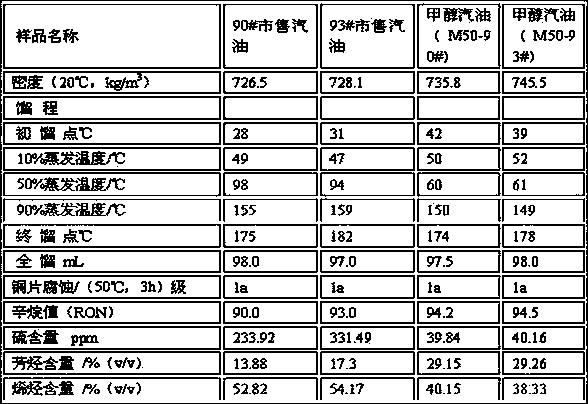

Methanol gasoline for vehicles

InactiveCN102492495AReduce swellingSimple preparation processLiquid carbonaceous fuelsAntioxidantDiethyl ether

The invention relates to a methanol gasoline for vehicles. The methanol gasoline is characterized in that the methanol gasoline is prepared by the following raw materials, by weight, 40-90 parts of gasoline, 60-10 parts of methanol, 0.5-8 parts of an assistant solvent, and 0.01-5 parts of a modifying agent, wherein the assistant solvent is prepared by mixing one or a plurality of materials selected from propanol, neopentyl glycol, pentaerythritol, isopropyl alcohol, tert-butyl alcohol, cerebral, diethyl ether, ethylene glycol, and oleic acid, the modifying agent is prepared from an alcohol solvent, a corrosion inhibitor, an anti-swelling agent, a phenol antioxidant, and a lubricant, the corrosion inhibitor is prepared by mixing one or a plurality of materials selected from dicyclohexylaminenitrite,102TB, triethylamine, and naphthenic acid, and the anti-swelling agent is prepared by mixing one or a plurality of materials selected from a 107PT anti-swelling agent, T102, and T115. The product of the present invention can be directly used on the vehicles adopting the gasoline as the fuel without change of the engines, and has characteristics of high octane number, good compatibility, strong low temperature separation resistance, full combustion, strong power performance, and the like.

Owner:江苏玖尚燃油发展有限公司

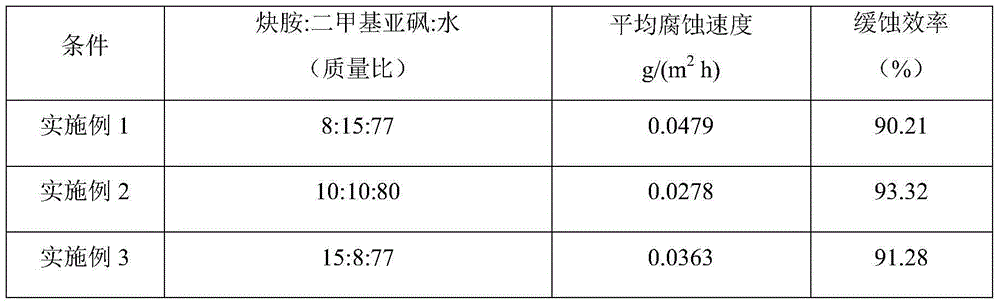

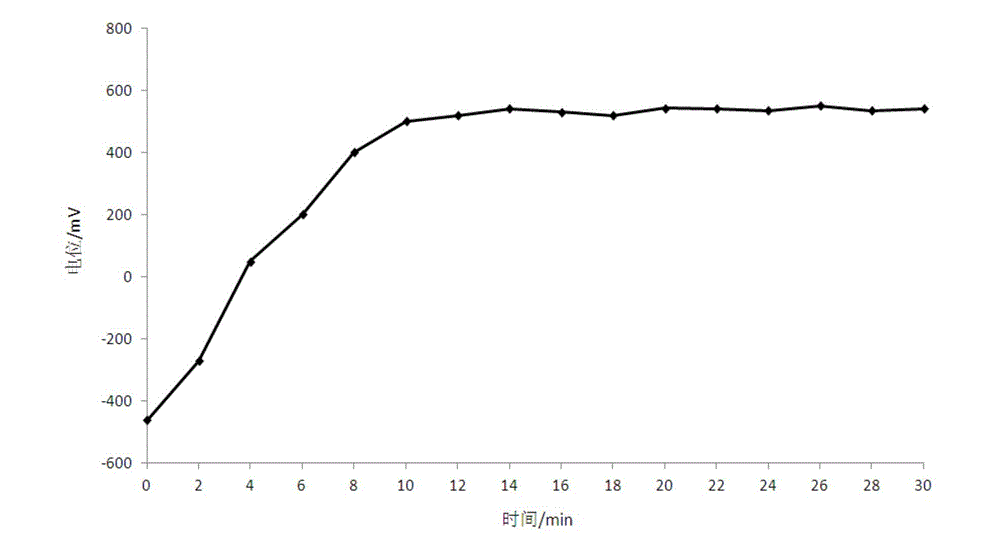

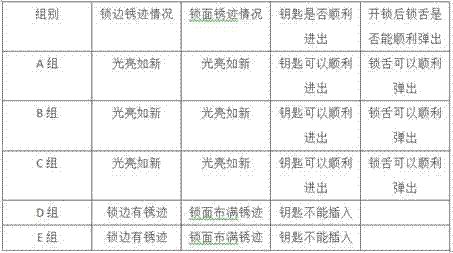

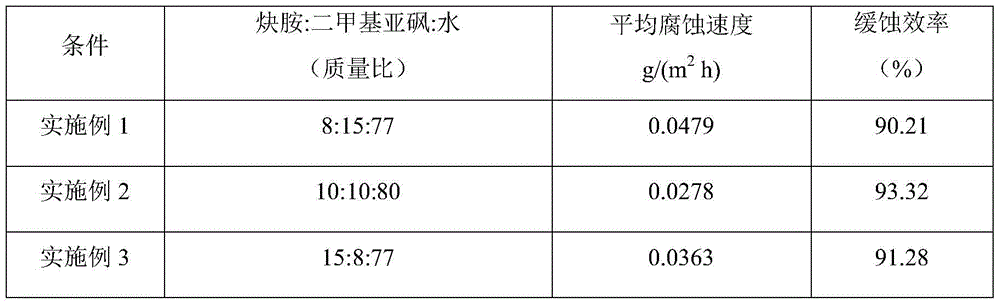

Vapor-phase corrosion inhibitor and preparation method thereof

The invention discloses a vapor-phase corrosion inhibitor and a preparation method thereof. The vapor-phase corrosion inhibitor comprises the following components in percentage by mass: 8-15% of alkynyl amine, 8-15% of organic solvent and the balance of water. The preparation method comprises the following steps: uniformly mixing the alkynyl amine and water according to the formula proportion to obtain an alkynyl amine water solution; and adding the organic solvent into the alkynyl amine water solution according to the formula proportion, and uniformly mixing to obtain the vapor-phase corrosion inhibitor. The vapor-phase corrosion inhibitor has higher saturated vapor pressure, has obvious corrosion inhibition effect on carbon steel atmospheric corrosion, and has enduring protection action. Compared with the bicyclohexylamine nitrite, cyclohexylamine carbonate and other vapor-phase corrosion inhibitors, the vapor-phase corrosion inhibitor disclosed by the invention has smaller toxic and side effects and more obvious corrosion inhibition effect. The vapor-phase corrosion inhibitor disclosed by the invention has the advantages of accessible raw materials, simple preparation technique and small toxic and side effects, can effectively lower the corrosion rate of the carbon steel atmospheric corrosion, and can prolong the service life of various steel apparatuses and facilities.

Owner:荆门铸鼎新材料有限公司 +1

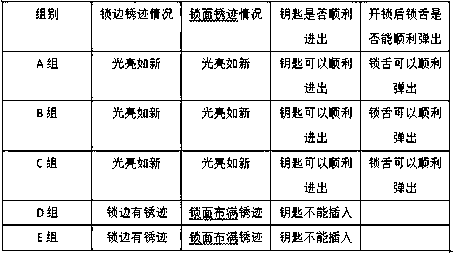

Machinery seal vapor phase anti-rust and preparation method thereof

The invention relates to a machinery seal vapor phase anti-rust oil comprising following ingredients in percentage by weight: 3-15 percent of barium dinonynalphthalene sulfonate, 3-15 percent of petroleum sodium sulfonate, 1-15 percent of dodecencylsuccinic acid, 0-5 percent of dicyclohexyl amine nitrite, 0-5 percent of ethanol and 5-88 percent of hydrocarbon solvent. A preparation method of the machinery seal vapor phase anti-rust oil comprises the following steps of (1) putting the 5-88 percent of hydrocarbon solvent in a mixing cylinder and heating to 45 DEG C; (2) putting the 3-15 percent of barium dinonynalphthalene sulfonate, the 3-15 percent of petroleum sodium sulfonate and the 1-15 percent of dodecencylsuccinic acid into the mixing cylinder in sequence and stirring for 1h; and (3) evenly mixing the 0-5 percent of dicyclohexyl amine nitrite and the 0-5 percent of ethanol, putting in the mixing cylinder and stirring for 1h to obtain the product. The invention can effectively prevent corrosion of chloride and sulfide, has good high-wet resistance, no toxicity and good heat stability and can be mixed with lubricating oil, hydraulic oil or punching oil after being diluted.

Owner:SHANGHAI JIUSHENG IND

Galvanized layer chromium-free passivating agent and preparation method thereof

ActiveCN104404485AImprove acid resistanceGood alkali resistanceMetallic material coating processesChromium freeHydrogen Sulfate

The invention discloses a galvanized layer chromium-free passivating agent and a preparation method thereof. The passivating agent comprises the following components: sodium hydrogen sulfate, sodium tripolyphosphate, sodium alkyl benzene sulfonate, ammonium acetate, alumina, starch, thiourea, dicyclohexylamine nitrite, methyl cellulose, methylparaben, ethylene glycol monostearate and deionized water. The preparation method includes: adding sodium hydrogen sulfate, sodium tripolyphosphate, sodium alkyl benzene sulfonate, ammonium acetate, and thiourea into the deionized water, stirring and mixing the materials evenly at room temperature to obtain a mixed solution 1; adding alumina, starch, dicyclohexylamine nitrite, methyl cellulose, methylparaben and ethylene glycol monostearate into ethanol absolute, subjecting ethanol to heating refluxing, and conducting filtering to obtain a solid mixture, and performing drying to obtain an intermediate 1; then adding the intermediate 1 into the mixed solution 1 obtained in step two, and conducting stirring mixing under a vacuum heating condition, thus obtaining the galvanized layer chromium-free passivating agent. The galvanized layer chromium-free passivating agent provided by the invention has excellent corrosion resistance.

Owner:WUXI EPIC TECH

Reinforcing steel bar inhibitor and preparation method thereof

The invention relates to a reinforcing steel bar inhibitor. The reinforcing steel bar inhibitor is prepared from the following components: 12 parts of sodium benzoate, 3 parts of sodium silicate, 3 parts of gluconic acid, 1 part of citric acid, 3 parts of thiourea, 6 parts of dicyclohexylaminenitrite, 8 parts of coal ash, 15 parts of nitrite, 4 parts of sodium hexametaphosphate, 7 parts of diethylenetriamine, 5 parts of thiourea, 2 parts of sodium benzoate and 2 parts of urotropin. The inhibitor provided by the invention is good in adaptability to cement, so that the performances of concrete can be improved properly; the permeation of a slow release medium into concrete is slowed down; meanwhile, a layer of compact chemical adsorption membrane can be formed on the surface of a reinforcing steel bar; a corrosion medium in a concrete pore solution and oxygen are insulated from being in direct contact with the reinforcing steel bar, so that the electrochemical corrosion cannot be carried out, thereby preventing the corrosion effect to the reinforcing steel bar.

Owner:青建集团股份公司

Concrete waterproofing agent

The invention discloses a concrete waterproofing agent which is prepared from the following raw materials in parts by weight: 15-23 parts of hydrophobic fumed silica, 9-16 parts of superfine slag powder, 5-10 parts of sodium tall oil pitch sulfonate, 5-9 parts of dicyclohexylamine nitrite, 3-6 parts of octadecylamine, 7-9 parts of octyl dodecyl polyglucosides, 1-5 parts of 4-p-phenylphenol, 6-10 parts of water-based trihydroxymethylaminomethane-epoxy resin, 3-6 parts of mill wood lignin, 3-5 parts of gypsum, 1-5 parts of ethylene glycol, 5-10 parts of polyvinylpyrrolidone and 8-11 parts of silica-coated titanium dioxide. The concrete waterproofing agent disclosed by the invention has the beneficial effects that the concrete waterproofing agent has a good waterproofing effect and has good water-reducing and impervious effects.

Owner:张桂华

High performance lubricating grease additive

Owner:QINGDAO YUXING INTELLIGENT TECH DEV CO LTD

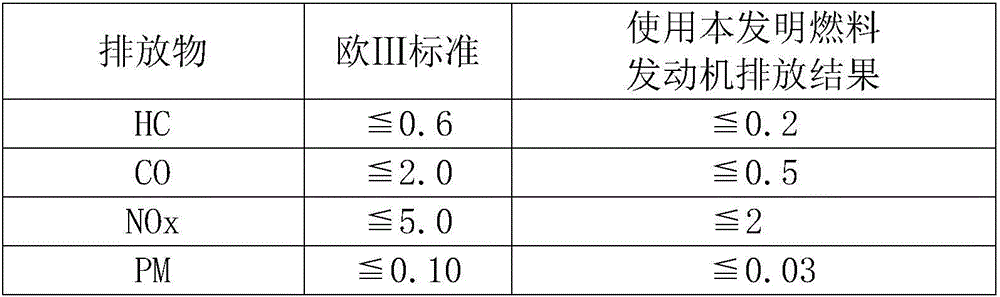

Synergistic emission reducing methanol fuel

InactiveCN106367132AHas a cleansing effectEffectively remove carbon depositsLiquid carbonaceous fuelsFuel additivesPropionateCombustion

The invention belongs to the technical field of fuel and particularly relates to a synergistic emission reducing methanol fuel which is prepared from the following raw materials in parts by weight: 60-90 parts of methanol, 20-44 parts of gasoline, 1-7 parts of coco fatty acid diethanol amide, 0.5-2.3 parts of 2-ethyl-4-methylimidazole, 0.5-2.3 parts of amyl propionate, 0.4-2.2 parts of methyl sec-butyl ether, 0.2-1.4 parts of glycerin, 0.2-1.4 parts of a combustion improver, 0.1-1.3 parts of an antioxidant, 0.03-0.21 part of dicyclohexylaminenitrite and 0.02-0.2 part of hydroxyethylidene diphosphonic acid. The synergistic emission reducing methanol fuel provided by the invention has the functions of cleaning, resisting oxidation, improving combustion and preventing corrosion and explosion, realizes good combustion performance and sufficient combustion, and is synergistic, energy-saving and emission-reducing.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Rapidly solidified metal passivator and preparation method thereof

InactiveCN105839085AFreeze fastEasy to useMetallic material coating processesSodium phosphatesPhosphoric acid

The invention discloses a rapidly solidified metal passivator and a preparation method thereof. The rapidly solidified metal passivator comprises the following raw materials in parts by weight: 20-30 parts of glucose, 10 to 40 parts of calcium chloride, 40 to 50 parts of boron anhydride, 40 to 50 parts of titanium dioxide, 20 to 30 parts of silicon dioxide, 10 to 20 parts of nickel chloride, 20 to 60 parts of silver nitrate, 10 to 20 parts of aluminium phosphate, 10 to 50 parts of sodium phosphate, 50 to 60 parts of dicyclohexylaminenitrite, 10 to 20 parts of methylcellulose, 20 to 30 parts of methylparaben, 10 to 60 parts of ethylene glycol monostearate, 50 to 80 parts of ammonium dihydrogen phosphate, 10 to 20 parts of molybdate and 50 to 60 parts of potassium sorbate. The preparation method comprises the steps of sequentially adding glucose, calcium chloride, boron anhydride, titanium dioxide, silicon dioxide and nickel chloride into silver nitrate; increasing the temperature for reaction; after cooling, adding the remaining components; and filtering to remove impurities. The rapidly solidified metal passivator can be quickly solidified, and the utilization is convenient.

Owner:WUXI EPIC TECH

Antirust stainless steel packing paper and its making process

InactiveCN1375432AEvenly distributedImprove bindingFlexible coversWrappersBenzoic acidProduction line

The stainless steel rust-preventing packaging paper is made up by uniformly spraying stainless steel rust-preventing agent on the surface of one side of wet paper base before which is fed into dryingcylinder on the production line of packaging paper, and its rust-preventing agent comprises ammonium citrate, benzoic acid, sodium nitrite, ammonium acetate, isopropanolamine, dicyclohexylamine nitrite, neckel and water.

Owner:郑东

Efficient road deicing agent and preparation method thereof

ActiveCN109777357AMelting ice fastAvoid corrosionOther chemical processesChemical industryFreeze thawingSodium lactate

The invention provides an efficient road deicing agent and a preparation method thereof. The electrochemical comprises, by weight, 0.1-1 part of polyethylene oxide, 0.2-0.3 part of potassium acetate,100-150 parts of a plant ash lixivium, 2-5 parts of an emulgator, 0.3-0.5 part of sodium citrate, 0.02-0.05 part of mercapto benzothiazole, 0.01-0.03 part of sodium polyaspartate, 0.2-0.4 part of sodium tetraborate, 0.4-0.6 part of sodium lactate, 0.3-0.6 part of dicyclohexylaminenitrite and 3-5 parts of diatom ooze dry powder. The deicing agent is prepared through dissolution, stirring, heating,repeated freeze thawing and other methods, with sylvite as a main deicing component, the deicing agent does not contain chloridion for corroding metal, efficient deicing is achieved, corrosion of thedeicing agent on the metal and pavement and damage of water containing the deicing agent after snow melting to vegetation can also be effectively prevented, and the deicing agent is an energy-saving,environment-friendly and efficient deicing agent.

Owner:内蒙古综合交通科学研究院有限责任公司

Formula of waterproof adhesion mortar

The invention relates to a formula of anti-cracking adhesion mortar which is prepared by mixing raw materials including, by weight, 18-26 parts of hydrophobic fumed silica, 10-15 parts of calcium stearate, 6-12 parts of mineral slag micropowder, 4.5-6.5 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, 9-18 parts of zinc oxide powder, 20-30 parts of an AF-2 high-effective water reducing agent,5-10 parts of glass fibers, 10-15 parts of aluminum potassium sulfate, 5-10 parts of tall oil asphalt sodium sulfonate, 8-16 parts of polymethyltriethoxysilane, 3-5 parts of aluminum dihydrogen phosphate, 2.5-4.5 parts of dicyclohexylamine nitrite, 3-5 parts of sodium borate, and 4-7 parts of an additive. The waterproof adhesion mortar has good anti-freezing property, anti-carbonizing performanceand wear-resistance. Compared with the prior art, the waterproof adhesion mortar contains zinc oxide powder, so that during an initial setting step of the adhesion mortar, the zinc oxide is neutralized with water and acidic and alkaline substances and then gradually generates H2 and O2, so that the zinc oxide powder is gasified and discharged from the mortar and meanwhile takes out a part of hydration heat, thus reducing generation of temperature shrinkage cracks.

Owner:不二新材料科技有限公司

Methanol fuel for diesel engine

InactiveCN106281484AGood miscibilityImprove frost resistanceLiquid carbonaceous fuelsFuel additivesHydroxybenzoate EthersTert butyl

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Antirust stainless steel packing paper and its making process

InactiveCN1168637CEvenly distributedImprove bindingFlexible coversWrappersProduction lineBenzoic acid

The stainless steel rust-preventing packaging paper is made up by uniformly spraying stainless steel rust-preventing agent on the surface of one side of wet paper base before which is fed into drying cylinder on the production line of packaging paper, and its rust-preventing agent comprises ammonium citrate, benzoic acid, sodium nitrite, ammonium acetate, isopropanolamine, dicyclohexylamine nitrite, neckel and water.

Owner:郑东

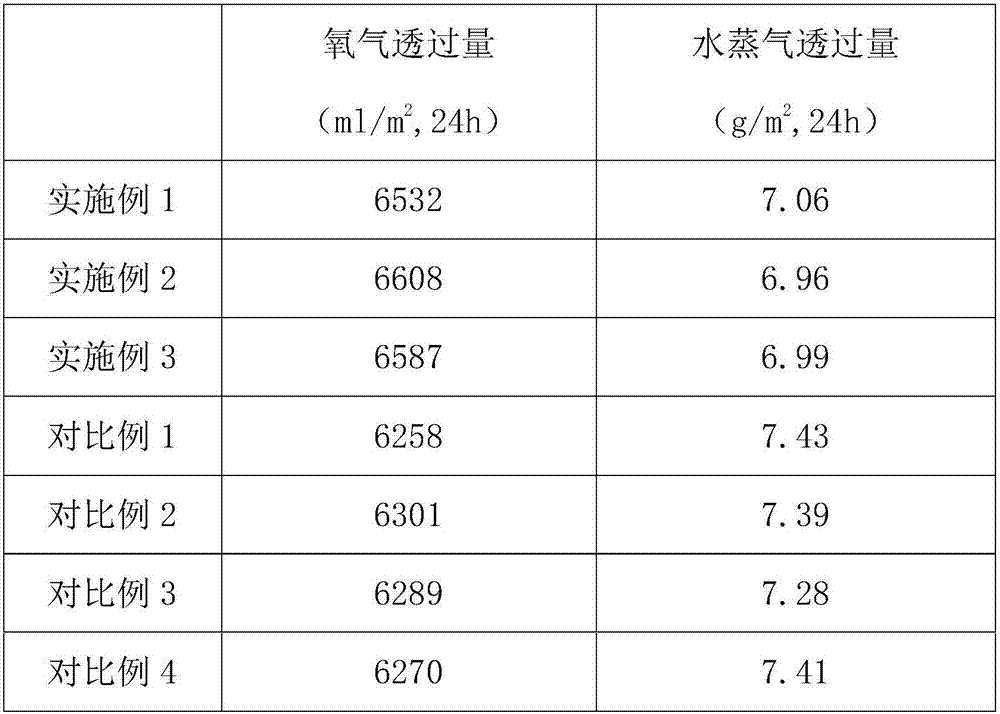

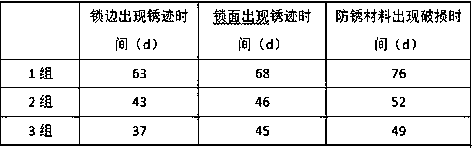

Preparation method and application of air-permeable and waterproof packaging material

The invention discloses a preparation method and application of an air-permeable and waterproof packaging material. The method comprises the following steps: heating ethylene-methylacrylate, polyisocyanate, maleic anhydride grafted polypropylene, poly(butylene adipate-co-terephthalate) and polyethylene glycol in a water bath; centrifuging and washing, and drying to obtain a first mixture; then after ultrasonically dispersing montmorillonite, epichlorohydrin resin and de-ionized water, adding dicyclohexylaminenitrite and methyl ethyl ketoxime; reacting and washing to prepare a second mixture; finally, adding the first mixture and the second mixture into a plasticizer, hydrogenated castor oil and dimethicone and mixing; extruding a mixture through a double-screw extruder, and carrying out die pressing and molding to obtain the finished-product packaging material. The air-permeable and waterproof packaging material prepared by the preparation method has a good ventilation effect and a strong waterproof property and has a good application prospect in medical equipment product packaging.

Owner:叶芳

Stretch-resistant composite packaging material and preparation method thereof

The invention discloses a stretch-resistant composite packaging material and a preparation method thereof. The stretch-resistant composite packaging material is prepared by using low-density polyethylene, sodium carboxymethyl starch and butyl methacrylate as the main components and adding propylene glycol alginate, a hexamethoxymethyl melamine resin, microcrystalline cellulose, beta-cyclodextrin, dicyclohexylamine nitrite, anilinomethyl triethoxy silane, isoborneol acrylate, rosin sodium soap, activated carbon, zinc stearate, nano titanium dioxide, a plasticizer and a coupling agent. The preparation method comprises the following steps: thermostatic water bath treatment, centrifugal separation, vacuum drying, grinding refinement, microwave treatment, compounding, plasticizing, melt extrusion, hot pressing and the like. The composite packaging material has the advantages of favorable stretch resistance, favorable flexing resistance and low flammability, can satisfy the industrial requirements, and has favorable application prospects.

Owner:苏州缔绿电子科技有限公司

Production formula for methanol gasoline

InactiveCN103911187ASolve miscibilityAvoid stabilityLiquid carbonaceous fuelsChlorobenzeneAntioxidant

The invention provides a production formula for methanol gasoline. The production formula is composed of a demulsifying agent, a solubilizer, an antioxidant, an anti-freezing agent, a stabilizer, a calorific value improver, a plasticizer and the like. The major technical formula of the methanol gasoline comprises the following components in percentage by weight: 50-80% of methanol, 20-50% of petrochemical gasoline, 10-20% of xylene, 0.05-0.3% of n-butyl alcohol, 0.5-2% of nitrobenzene, 0.05-0.2% of dicyclohexylaminenitrite, 0.2-0.4% of glyceryl triacetate, 0.005-0.03% of 1,2-dibromoethane, 0.05-0.3% of isopropanol, 2-5% of chlorobenzene, 10-20% of ethylbenzene, 0.05-0.2% of iso-butylamine and 0.002-0.05% of n-octane. A series application problems of the methanol gasoline are effectively solved by virtue of simple and scientific addition and an advanced re-proportioning production technology; the methanol gasoline does not layer and emulsify when the ratio of the methanol gasoline to water is 2%; the methanol gasoline is stable in properties and normal in cold start at minus 20 DEG C, also is strong in power and has no corrosion to each part of an engine; the raw materials of the methanol gasoline are just of industrial-level specifications so that the cost is greatly reduced; the production process of the methanol gasoline is simple; the methanol gasoline is applicable to various oil-consuming vehicles.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Stable fuel additive

InactiveCN104449911AChemically stableIncrease profitLiquid carbonaceous fuelsHeptyl alcoholN-Propyl alcohol

The invention relates to a stable fuel additive, which is prepared from the following raw materials in parts by weight: 6-11 parts of ethylene glycol methyl ether, 6-8 parts of isobutyl alcohol, 7-10 parts of a nanoparticle magnetic solution, 3-9 parts of sorbitan monooleate, 4-7 parts of normal propyl alcohol, 6-9 parts of dibutyl hydroxytoluene, 3-8 parts of dicyclohexylamine nitrite, 5-7 parts of n-heptanol, 2-6 parts of n-butyl alcohol, 2-5 parts of OP-15, 1-5 parts of a dispersing agent, 3-5 parts of methylsilicone oil and 3-7 parts of linoleic acid. The stable fuel additive provided by the invention has the beneficial effects of being stable in chemical property and not easy to go bad; meanwhile, the use ratio of the fuel is improved; the resource waste is reduced; the stable fuel additive has an excellent economic value.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Emulsion type diesel additive

InactiveCN104357106AImprove powerIncrease profitLiquid carbonaceous fuelsOleic Acid TriglycerideEthyl acrylate

The invention discloses an emulsion type diesel additive, which is prepared from the following raw materials in parts by weight: 9 to 15 parts of ethyl acrylate, 6 to 10 parts of dicycloxylamine nitrite, 3 to 6 parts of methyl acrylate, 5 to 9 parts of dimethylacetamide, 2 to 6 parts of barium hydroxide, 3 to 5 parts of animal oleic acid, 6 to 8 parts of isooctyl nitrate, 3 to 7 parts of a purification dispersant, 3 to 8 parts of succinimide, 1 to 5 parts of oleic acid, 4 to 10 parts of acetamide, 1 to 3 parts of ethanol and 2 to 5 parts of isopropyl alcohol. The emulsion type diesel additive has the benefits that the power performance can be well improved, the utilization rate of a fuel can be increased, the emission of waste can be reduced, and the environment is protected.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

A kind of chromium-free passivating agent for galvanized layer and preparation method thereof

ActiveCN104404485BImprove acid resistanceGood alkali resistanceMetallic material coating processesChromium freeHydrogen Sulfate

Owner:WUXI EPIC TECH

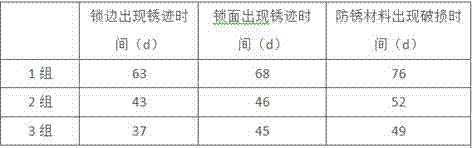

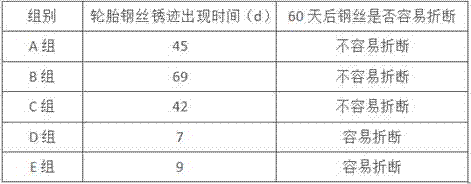

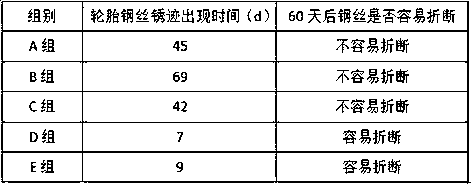

Gaseous phase rust-resisting material for rust-resisting seal of tire bead steel wire and preparation method of gaseous phase rust-resisting material

ActiveCN106976285AReduce breakageImprove integritySynthetic resin layered productsLaminationGas phaseDistilled water

The invention provides a gaseous phase rust-resisting material for rust-resisting seal of a tire bead steel wire. The rust-resisting material comprises a loading layer, a volatile layer, a permeation layer and a protective layer; and the invention further provides a preparation method of the gaseous phase rust-resisting material for the rust-resisting seal of the tire bead steel wire. The method comprises a preparation step of the volatile layer; the volatile layer is a non-woven fabric layer; non-woven fabric is subjected to coating processing; an antirust agent solution is adopted as a coating agent; and the antirust agent solution is prepared from the following raw materials: dicyclohexylamine nitrite, polyethylene glycol and distilled water. According to a gaseous phase sustained-release material prepared by the invention, rust-resisting material damage caused in the process of use due to carrying the tire bead steel wire can be reduced by a large margin; the completeness of the rust-resisting material is improved to the maximum extent; the rust-resisting capacity and rust-resisting time are improved; and the acid and alkali resistant capacity, the anti-aging capacity and the heat resistant capability are improved.

Owner:SHANDONG DAYE

A kind of vapor phase corrosion inhibitor and preparation method thereof

The invention discloses a gas phase corrosion inhibitor and a preparation method thereof. The vapor phase corrosion inhibitor comprises 8% to 15% of alkyne amine and 8% to 15% of organic solvent according to mass percentage, and the balance is water. Its preparation method comprises the following steps: first, uniformly mix the alkyne amine and water in the formula ratio to obtain an aqueous solution of the alkyne amine; then, add an organic solvent in the formula ratio to the aqueous solution of the alkyne amine and mix evenly to obtain the gas phase corrosion inhibitor agent. The gas-phase corrosion inhibitor has a high saturated vapor pressure, has a significant corrosion inhibition effect on atmospheric corrosion of carbon steel, and has a long-lasting protective effect. At the same time, compared with gas-phase corrosion inhibitors such as dicyclohexylamine nitrite and cyclohexylamine carbonate, the gas-phase corrosion inhibitor provided by the invention has less toxic and side effects and more significant corrosion inhibition effect. The gas-phase corrosion inhibitor provided by the invention has easy-to-obtain raw materials, simple preparation process, and less toxic and side effects, can effectively reduce the corrosion rate of atmospheric corrosion of carbon steel, and prolong the service life of various iron and steel instruments and equipment.

Owner:荆门铸鼎新材料有限公司 +1

A kind of vapor phase antirust material for bead steel wire antirust sealing and preparation method thereof

ActiveCN106976285BReduce breakageImprove integritySynthetic resin layered productsLaminationGas phasePolyethylene glycol

Owner:SHANDONG DAYE

Additive for producing high-performance methanol gasoline

The invention discloses a technical formula of an additive for producing high-performance methanol gasoline. The technical formula of the additive for producing the high-performance methanol gasolinemainly comprises the following components by weight percentage: 20-30 percent of isobutanol, 0.1-2.5 percent of 2,4-di-tert-butyl-4 cresol, 25-40 percent of isoamylol, 8-16 percent of dioctyl phthalate, 3-10 percent of dioctanol, 0.05-0.1 percent of methylcyclopentadienyl manganese tricarbonyl, 1-3 percent of dicyclohexylammonium nitrite, 0.5-1.5 percent of glyceryl triacetate and 0.5-3 percent of mixture of aldehyde condensation compounds. The methanol gasoline prepared by the additive has the advantages that methanol and gasoline can be stably and mutually soluble, rubber and metal parts of an automobile are protected; cold start of the automobile is easily realized, the combustion of the gasoline is sufficient and the power of the automobile is enhanced.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Anti-cracking bonding mortar for wallboard connection

The invention relates to an anti-cracking bonding mortar for wallboard connection. The anti-cracking bonding mortar is characterized by being prepared through mixing of the following raw materials byweight: 18-26 parts of hydrophobic fumed silica, 10-15 parts of zeolite powder, 6-12 parts of superfine slag powder, 4.5-6.5 parts of 2-phosphonobutane-1, 2, 4-tricarboxylic acid, 9-18 parts of zinc oxide powder, 20-30 parts of an AF-2 type superplasticizer, 5-10 parts of lotus leaf element, 10-15 parts of aluminum potassium sulfate, 5-10 parts of tall oil-asphalt sodium sulfonate, 8-16 parts of polypropylene glycol fiber, 3-5 parts of sodium bentonite, 2.5-4.5 parts of dicyclohexylamine nitrite, 3-5 parts of ethoxylated lanolin, and 4-7 parts of an assistant. The anti-cracking bonding mortarprovided by the invention has frost resistance, carbonization resistance and wear resistance superior to other cement. Compared with the existing formula, the formula adopted by the invention is addedwith zinc oxide powder, in the initial setting process, the bonding mortar neutralizes with water, acidic and alkaline substances, hydrogen and oxygen are gradually separated and are discharged fromthe bonding mortar in a gas form, at the same time part of hydration heat is taken away, thus reducing temperature shrinkage cracks.

Owner:不二新材料科技有限公司

Method for reducing cold filter plugging point of bio-fuel

InactiveCN107974306ALower cold filter pointImproving the freezing point of biofuelsLiquid carbonaceous fuelsBiofuelCold filter plugging point

The invention belongs to the technical field of fuel preparation and in particular relates to a method for reducing a cold filter plugging point of bio-fuel. The preparation method comprises the following steps: 1) taking fatty acid methyl ester and adding isopropyl alcohol which accounts for 5 to 10 percent of the weight of the fatty acid methyl ester, glyceryl triacetate which accounts for 0.3 to 0.8 percent of the weight of the fatty acid methyl ester and dicyclohexylaminenitrite which accounts for 0.2 to 1.4 percent of the weight of the fatty acid methyl ester respectively; 2) putting allthe raw materials into a high-speed mixing machine and stirring for 18 to 26min at 50 to 60 DEG C at a high speed; 3) carrying out ultrasonic treatment for 15 to 25min under the frequency of 75 to 95kHz. The bio-fuel prepared by the method has a relatively low cold filter plugging point and can be used for replacing diesel oil; an engine does not need to be replaced.

Owner:丰泰能源有限公司

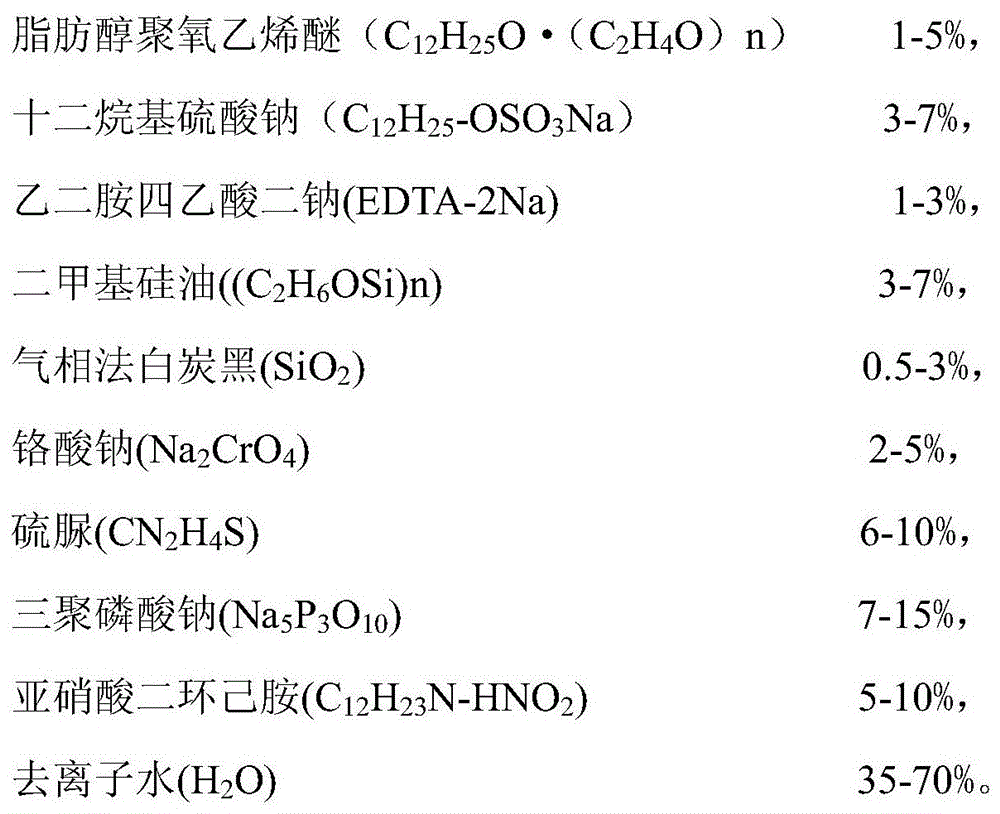

A kind of pickling additive and preparation method thereof

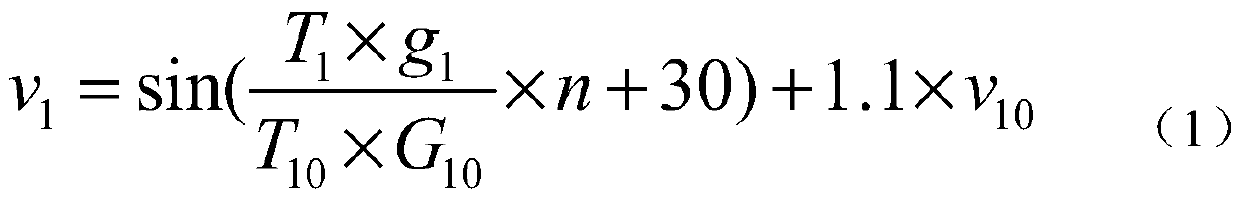

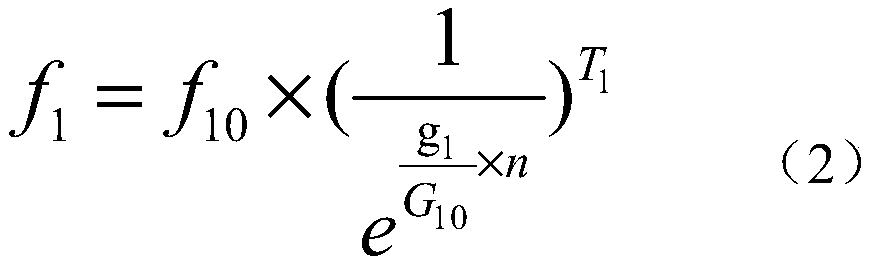

The invention relates to a novel pickling additive and a preparation method thereof. The pickling additive comprises the following components by weight ratio: 1-5% of fatty alcohol polyoxyethylene ether, 3-7% of sodium lauryl sulfate, Disodium edetate 1‑3%, simethicone 3‑7%, fumed silica 0.5‑3%, sodium chromate 2‑5%, thiourea 6‑10%, sodium tripolyphosphate (Na5P3O10) 7‑15%, dicyclohexylamine nitrite 5‑10%, deionized water 35‑70%. The pickling additive of the present invention can quickly remove the scale on the steel surface, form an adsorption protective film on the steel surface, effectively suppress the escape of hydrogen chloride gas (acid mist) in the pickling process, and improve the utilization rate of hydrochloric acid; Operating environment, reducing air pollution, has good environmental benefits, and helps enterprises to achieve clean production.

Owner:江门市三清环境技术工程有限公司

A kind of efficient road deicing agent and preparation method thereof

ActiveCN109777357BMelting ice fastAvoid corrosionOther chemical processesChemical industrySodium lactateFreeze thawing

The invention provides an efficient road deicing agent and a preparation method thereof. The electrochemical comprises, by weight, 0.1-1 part of polyethylene oxide, 0.2-0.3 part of potassium acetate,100-150 parts of a plant ash lixivium, 2-5 parts of an emulgator, 0.3-0.5 part of sodium citrate, 0.02-0.05 part of mercapto benzothiazole, 0.01-0.03 part of sodium polyaspartate, 0.2-0.4 part of sodium tetraborate, 0.4-0.6 part of sodium lactate, 0.3-0.6 part of dicyclohexylaminenitrite and 3-5 parts of diatom ooze dry powder. The deicing agent is prepared through dissolution, stirring, heating,repeated freeze thawing and other methods, with sylvite as a main deicing component, the deicing agent does not contain chloridion for corroding metal, efficient deicing is achieved, corrosion of thedeicing agent on the metal and pavement and damage of water containing the deicing agent after snow melting to vegetation can also be effectively prevented, and the deicing agent is an energy-saving,environment-friendly and efficient deicing agent.

Owner:内蒙古综合交通科学研究院有限责任公司

A kind of steel rust inhibitor

Owner:青岛理工建业检测科技有限公司

Compound corrosion inhibitor suitable for corrosive medium in gas phase region of storage tank and preparation method of compound corrosion inhibitor

The invention discloses a compound corrosion inhibitor suitable for a corrosive medium in a gas phase region of a storage tank and a preparation method of the compound corrosion inhibitor, and relates to the field of corrosion and protection of the storage tank, the compound corrosion inhibitor is composed of glycine, dicyclohexylamine nitrite, carboxylate and glucose, the mass fraction of the amino acetic acid is 10%-75%, the mass fraction of the dicyclohexylamine nitrite is 10%-55%, the mass fraction of the carboxylate is 2%-6%, and the mass fraction of the glucose is 5%-10%; the compound corrosion inhibitor is especially suitable for a neutral or acidic corrosive medium, and can effectively inhibit the corrosion phenomenon of carbon steel in the neutral or acidic medium; according to the compound corrosion inhibitor, through a corrosion inhibitor compounding and synergistic method, the synergistic effect of all the components is fully exerted, and then a good corrosion inhibition effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com