Preparation method and application of air-permeable and waterproof packaging material

A packaging material, breathable and waterproof technology, applied in the field of packaging materials, can solve the problems of poor air permeability, easy surface pollution, environmental pollution, etc., and achieve the effects of improved performance, strong waterproof performance, and good breathable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

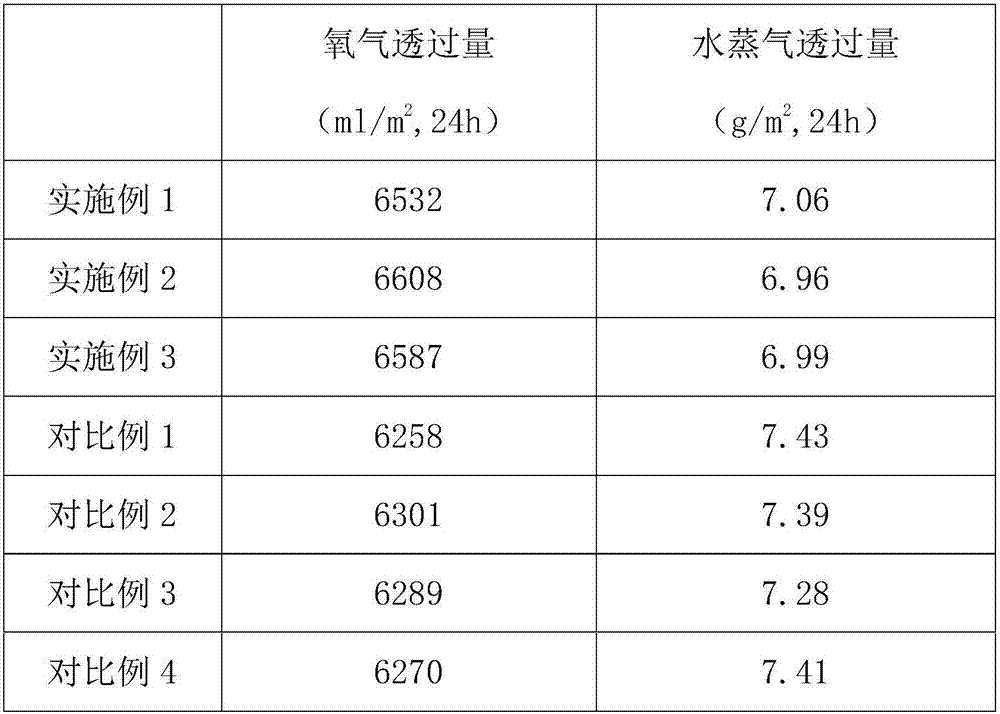

Examples

Embodiment 1

[0021] (1) Put 40 parts of ethylene-methyl acrylate, 22 parts of polyisocyanate, 10 parts of maleic anhydride grafted polypropylene, and 6 parts of polybutylene adipate terephthalate into a constant temperature water bath, and add 1.5 times quality polyethylene glycol, heated in a water bath, reacted at a constant temperature of 80°C for 3 hours, centrifuged after discharging, washed the separated mixture twice with absolute ethanol, and then dried it in a vacuum drying oven at a drying temperature of 50°C, the drying time is 8 hours to obtain the first mixture;

[0022] (2) Add 8 parts of montmorillonite, 7 parts of chloroether resin, and 150 parts of deionized water into the ultrasonic disperser, and disperse until uniform, the ultrasonic power is 600W, the ultrasonic time is 60 minutes, and then dicyclohexylamine nitrite is added 3 parts, 2 parts of methyl ethyl ketone oxime, stirred and reacted in a nitrogen atmosphere at 80°C for 1 hour, filtered and washed twice with abs...

Embodiment 2

[0027] (1) Put 45 parts of ethylene-methyl acrylate, 24 parts of polyisocyanate, 11 parts of maleic anhydride grafted polypropylene, and 7 parts of polybutylene adipate terephthalate into a constant temperature water bath, add 1.5 times High-quality polyethylene glycol, heated in a water bath, and reacted at a constant temperature of 80 ° C for 3 hours, centrifuged after discharge, washed the separated mixture with absolute ethanol for 3 times, and then placed it in a vacuum drying oven for drying. The drying temperature is 55°C, the drying time was 9 hours to obtain the first mixture;

[0028] (2) Add 10 parts of montmorillonite, 8 parts of chloroether resin, and 155 parts of deionized water into the ultrasonic disperser, and disperse until uniform by ultrasonic. The ultrasonic power is 600W, and the ultrasonic time is 75 minutes, and then dicyclohexylamine nitrite is added 4 parts, 3 parts of methyl ethyl ketone oxime, stirred and reacted in a nitrogen atmosphere at 85°C for...

Embodiment 3

[0033] (1) Put 50 parts of ethylene-methyl acrylate, 26 parts of polyisocyanate, 12 parts of maleic anhydride grafted polypropylene, and 8 parts of polybutylene adipate terephthalate into a constant temperature water bath, add 1.5 times High quality polyethylene glycol, heated in a water bath, reacted at a constant temperature of 80°C for 3 hours, centrifuged after discharging, washed the separated mixture 4 times with absolute ethanol, and then placed it in a vacuum drying oven for drying. The drying temperature was 60°C, the drying time is 10 hours to obtain the first mixture;

[0034] (2) Add 12 parts of montmorillonite, 9 parts of chloroether resin, and 160 parts of deionized water into an ultrasonic disperser, ultrasonically disperse until uniform, ultrasonic power is 600W, ultrasonic time is 90 minutes, and then dicyclohexylamine nitrite is added 5 parts, 4 parts of methyl ethyl ketone oxime, stirred and reacted in a nitrogen atmosphere at 90°C for 2 hours, filtered and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com