Reinforcing steel bar inhibitor and preparation method thereof

The technology of steel bar rust inhibitor and sodium benzoate, applied in the field of building materials, can solve the problems of unstable passivation film on the surface of steel bars, pitting corrosion of steel bars, etc., and achieve the effects of avoiding the decline of the protection effect, slowing the penetration, and reducing the dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

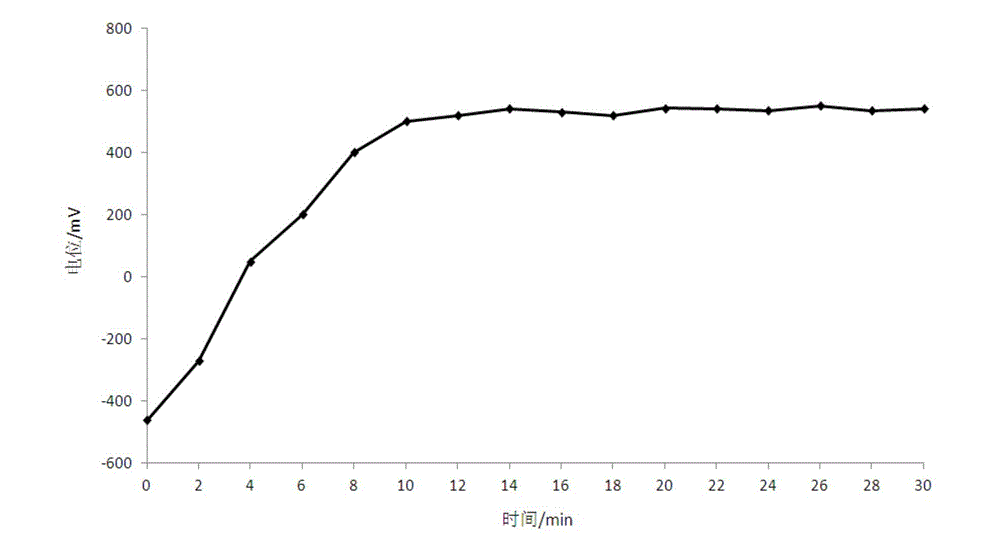

Image

Examples

Embodiment Construction

[0012] The rust inhibitor for steel bars of the present invention comprises the following components, 12 parts of sodium benzoate, 3 parts of sodium silicate, 3 parts of gluconic acid, 1 part of citric acid, 3 parts of thiourea, 6 parts of dicyclohexylamine nitrite, pulverized coal Ash 8 parts, nitrite 15 parts, sodium hexametaphosphate 4 parts, diethylenetriamine 7 parts, thiourea 5 parts, sodium benzoate 2 parts, urotropine 2 parts.

[0013] The method of steel bar rust inhibitor of the present invention comprises the following steps,

[0014] (1) Mix 12 parts of sodium benzoate, 3 parts of sodium silicate, 3 parts of gluconic acid, 1 part of citric acid and 3 parts of thiourea, adjust the pH to 3~4 with 10% hydrochloric acid, and heat to 110~ 120°C, react for 10 hours, distill off the reaction water to obtain the crude product;

[0015] (2) Add the crude product obtained in step (1) to 4% NaOH aqueous distilled water and wash until neutral;

[0016] (3) Add 6 parts of dic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com