Synergistic emission reducing methanol fuel

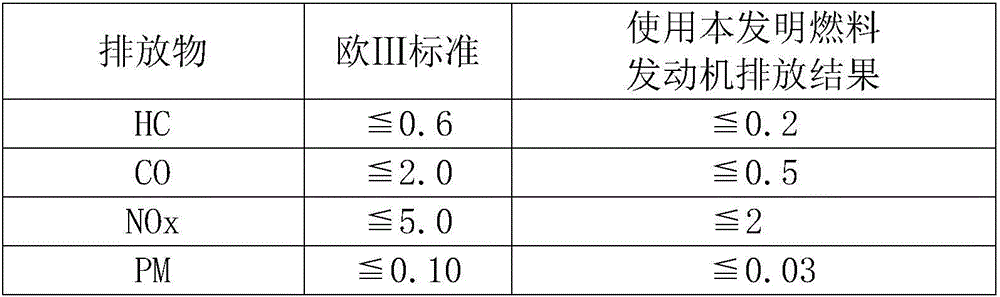

A methanol fuel and methanol technology, which is applied to fuels, fuel additives, and liquid carbon-containing fuels, etc., can solve the problems that the combustion efficiency of diesel cannot be improved, the normal operation of internal combustion engines is reduced, and the effect is not ideal, and the rubber swelling can be solved. problems, extended trial period, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Synergistic and emission-reducing methanol fuel is made of the following raw materials in parts by weight (just stir them evenly at room temperature): 60 parts of methanol, 44 parts of gasoline, 1 part of coconut acid diethanolamide, 2-ethyl-4-methanol 2.3 parts of imidazole, 0.5 parts of amyl propionate, 2.2 parts of methyl sec-butyl ether, 0.2 parts of glycerol, 1.4 parts of combustion enhancer, 0.1 parts of antioxidant, 0.21 parts of aminotrimethylene phosphonic acid, hydroxyethylidene diphosphine 0.02 parts of acid.

[0026] The above-mentioned combustion improver is a mixture of 20 parts by weight of ethyl tert-butyl ether, 7 parts by weight of naphthenic acid and 11 parts by weight of isoamyl alcohol.

[0027] The above antioxidant is a mixture of 10 parts by weight of p-methoxyphenol, 20 parts by weight of diethyl-p-phenylenediamine and 5 parts by weight of p-tert-butylcatechol.

Embodiment 2

[0029] Synergistic and emission-reducing methanol fuel is made of the following raw materials in parts by weight (at room temperature, just stir well): 65 parts of methanol, 40 parts of gasoline, 2 parts of cocoic acid diethanolamide, 2-ethyl-4-methanol 2 parts of imidazole, 0.8 parts of amyl propionate, 1.9 parts of methyl sec-butyl ether, 0.4 parts of glycerol, 1.2 parts of combustion enhancer, 0.3 parts of antioxidant, 0.18 parts of dicyclohexylamine nitrite, hydroxyethylidene Phosphonic acid 0.05 part.

[0030] The above-mentioned combustion improver is a mixture of 18 parts by weight of ethyl tert-butyl ether, 9 parts by weight of naphthenic acid and 10 parts by weight of isoamyl alcohol.

[0031] The above antioxidant is a mixture of 12 parts by weight of p-methoxyphenol, 18 parts by weight of diethyl-p-phenylenediamine and 6 parts by weight of p-tert-butylcatechol.

Embodiment 3

[0033] Synergistic and emission-reducing methanol fuel is made of the following raw materials in parts by weight (just stir them evenly at room temperature): 70 parts of methanol, 36 parts of gasoline, 3 parts of cocoic acid diethanolamide, 2-ethyl-4-methanol 1.7 parts of imidazole, 1.1 parts of pentyl propionate, 1.7 parts of methyl sec-butyl ether, 0.6 parts of glycerin, 1 part of combustion enhancer, 0.5 parts of antioxidant, 0.15 parts of dicyclohexylamine nitrite, hydroxyethylidene Phosphonic acid 0.08 parts.

[0034] The above-mentioned combustion improver is a mixture of 16 parts by weight of ethyl tert-butyl ether, 11 parts by weight of naphthenic acid and 9 parts by weight of isoamyl alcohol.

[0035] The above antioxidant is a mixture of 14 parts by weight of p-methoxyphenol, 16 parts by weight of diethyl-p-phenylenediamine and 7 parts by weight of p-tert-butylcatechol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com