A kind of vapor phase corrosion inhibitor and preparation method thereof

A gas-phase corrosion inhibitor and organic solvent technology, applied in the field of gas-phase corrosion inhibitor and its preparation, can solve the problems of insignificant effect, large toxic and side effects, and achieve the effect of remarkable effect, small toxic and side effects, and good volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the gas phase corrosion inhibitor provided by the present invention includes the following steps: firstly mix the alkynamine and water in a formula ratio to obtain an alkyneamine aqueous solution; then, add an organic solvent in a formula ratio to the alkynamine aqueous solution and mix uniformly , The vapor phase corrosion inhibitor is obtained. The alkyneamine is preferably propargylamine; the organic solvent is preferably a polar aprotic organic solvent, more preferably dimethyl sulfoxide.

[0024] Among the vapor phase corrosion inhibitors provided by the present invention, alkynylamine can achieve a higher saturated vapor pressure due to its strong volatility, but the excessive volatility of alkynylamine alone causes the corrosion inhibitor to be unstable. The invention makes the corrosion inhibitor more stable by adding the organic solvent, and by selecting the type of the alkynamine and the organic solvent and adjusting the ratio, the volat...

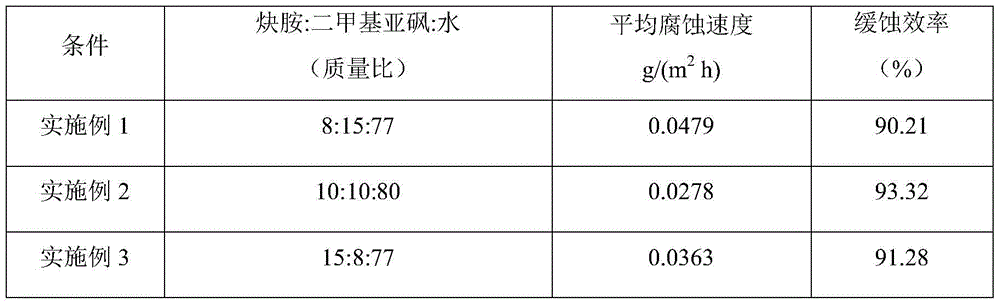

Embodiment 1

[0027] A gas phase corrosion inhibitor, comprising 8% propargylamine and 15% dimethyl sulfoxide organic solvent according to mass percentage, and the balance is water.

[0028] The gas phase corrosion inhibitor is prepared as follows. First, 8 parts of propargylamine and 77 parts of water are uniformly mixed according to the mass parts to obtain an aqueous solution of propargylamine; then, a formula ratio of dimethyl is added to the aqueous solution of propargylamine The sulfoxide organic solvent is mixed evenly to obtain a clear light yellow vapor phase corrosion inhibitor. The water is double distilled water.

Embodiment 2

[0030] A gas phase corrosion inhibitor, comprising 10% propargylamine and 10% dimethyl sulfoxide organic solvent according to mass percentage, and the balance is water.

[0031] The gas phase corrosion inhibitor is prepared as follows: first, 10 parts of propargylamine and 80 parts of water are uniformly mixed according to the mass parts to obtain an aqueous solution of propargylamine; then, a formula ratio of dimethylmethylene is added to the aqueous solution of propargylamine The sulfone organic solvent is evenly mixed to obtain a clear light yellow vapor phase corrosion inhibitor. The water is double distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com