A heat exchange method for liquefied natural gas cold energy for high-temperature cold energy users

A technology of liquefied natural gas and heat method, which is applied in applications, household appliances, household refrigeration devices, etc., can solve the problems of large investment in civil engineering, difficulties in detection and control, and large demand for refrigerants, etc., to reduce equipment investment and land occupation Large area, good operating flexibility, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

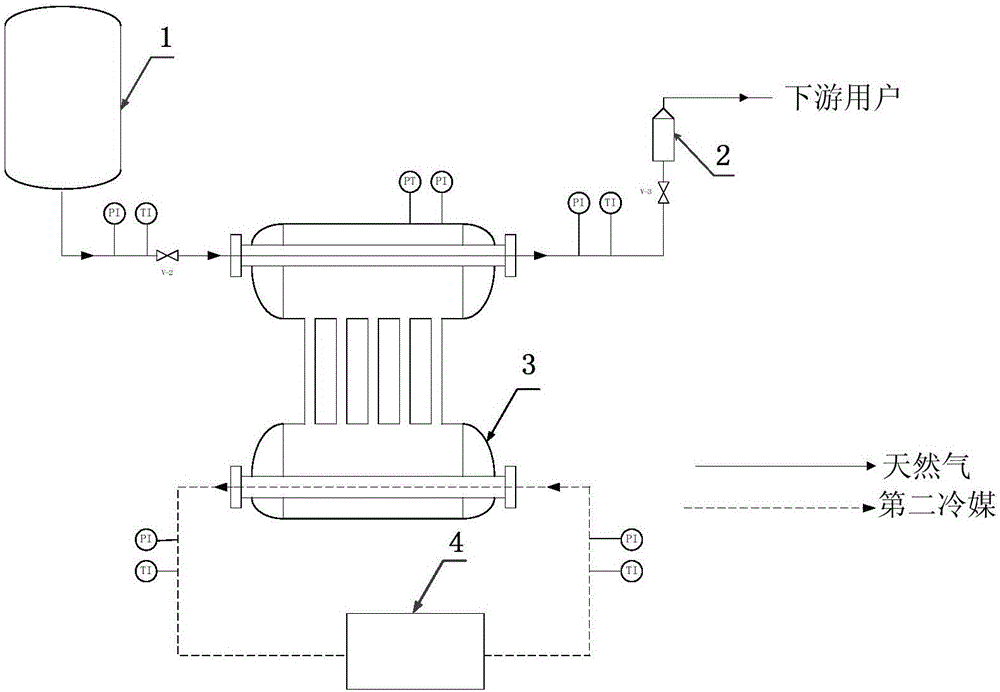

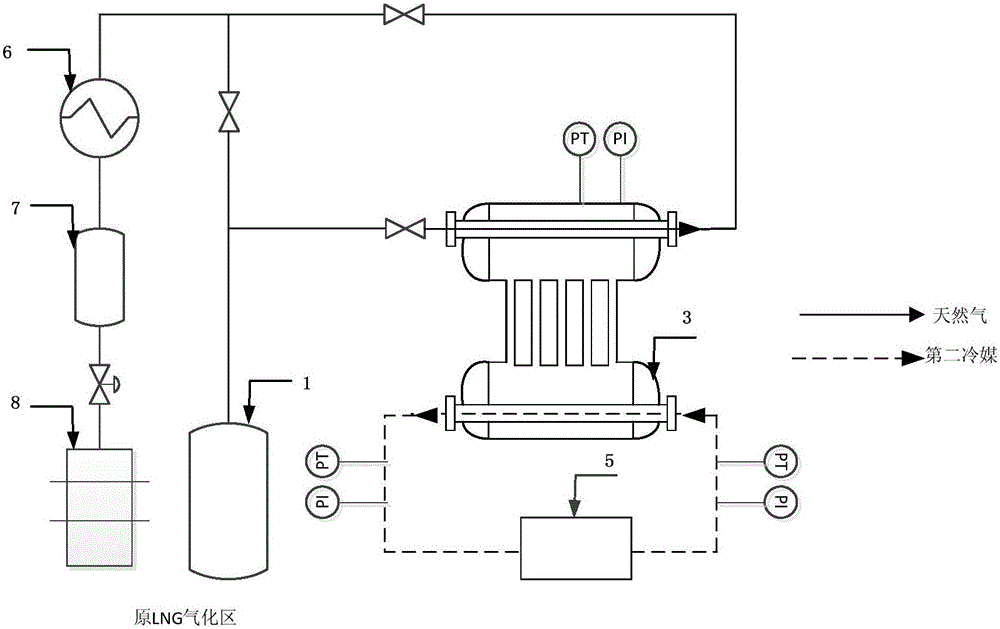

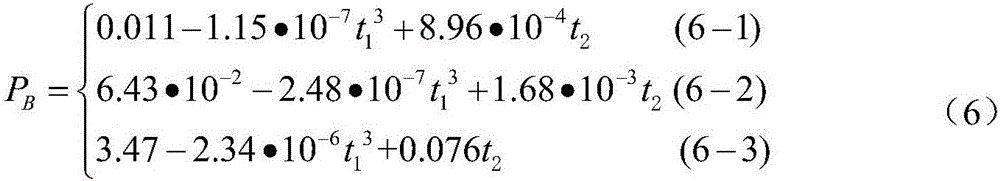

[0043] LNG heavy-duty trucks are supplied with gas in the form of on-board LNG bottles. At present, when the cooling capacity is 3kW, it can meet the cooling needs of most heavy-duty LNG vehicles. It is known that the total liquefaction pressure of R404A at 0°C is about 6.4 bar, so the total system pressure P is set to 6.4 bar in this example; when the required cooling capacity is 3kW, the temperature of R404A during the heat exchange between R404A and LNG is given by During the change process from 10°C to 0°C, the mass flow rate of R404A calculated by Aspen simulation is about 62kg / h. in such as figure 2 As shown, the LNG storage tank 1, the heater 6, the surge tank 7, and the engine 8 together form the original LNG gasification zone. The overlapping heat exchanger 3 is composed of two heat exchangers, each of which is a single shell-side double-tube heat exchanger; the lower heat exchanger of the overlapping heat exchanger 3 in this embodiment is an evaporation device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com