Photosensitive composition excellent in light absorption and suitable for forming fine pattern

A technology of photosensitive composition and photosensitive resin, which is applied to photosensitive materials used in opto-mechanical equipment, photo-engraving process of pattern surface, optics, etc., can solve the problems such as time-consuming and production efficiency decline, and achieve excellent absorbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~3

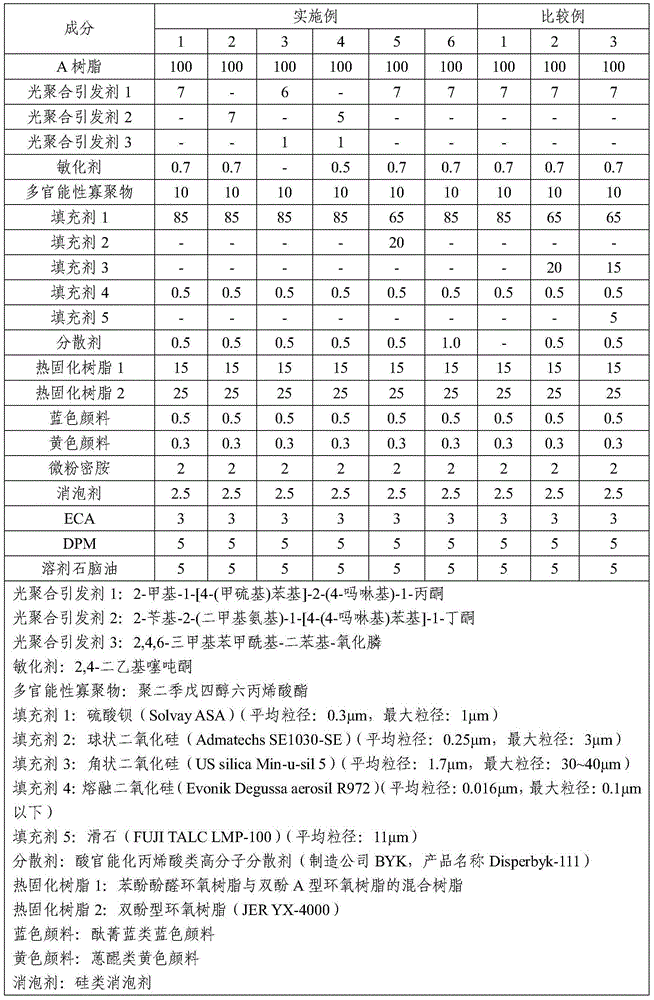

[0066] The components shown in the following Table 1 were prepared and stirred in the amounts shown in Table 1, and dispersed with a three-roll mill to obtain the photosensitive compositions of Examples 1-6 and Comparative Examples 1-3, respectively.

[0067] Table 1

[0068]

[0069]

[0070] The following evaluation was performed about the soldering resist film formed from the photosensitive composition of each Example and the comparative example prepared above.

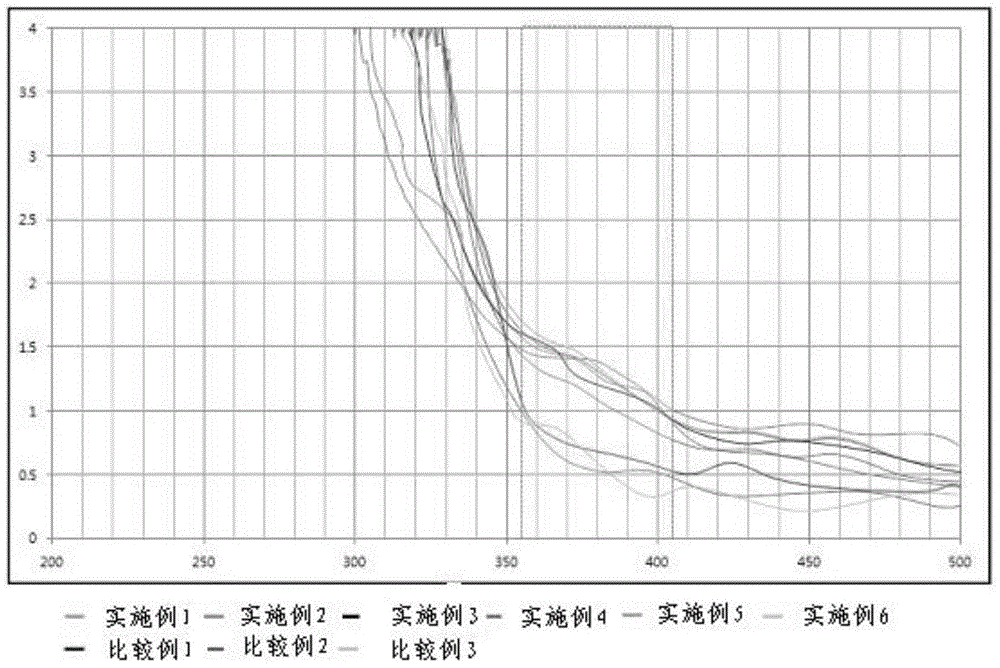

[0071] Absorbance

[0072] After coating the photosensitive composition on a high-transmittance optical glass plate, it was dried at 80° C. for 30 minutes in a hot-air circulation oven to obtain a glass plate-shaped dry coating film sample. Absorbance was measured for the prepared dried coating film samples. As a UV-VIS spectrophotometer, Varian's Cary50conc product was used, and the absorbance with respect to the glass plate before coating was set as a baseline. Absorbance charts measured for the compos...

Embodiment 7

[0081] Dilute the photosensitive composition of Example 1 with methyl ethyl ketone, apply the diluted product on the carrier film, and pass through 2 minutes at 60°C, 2 minutes at 80°C, 2 minutes at 110°C, and 2 minutes at 60°C. The temperature distribution was performed for 3 minutes to form a dry coating film with a thickness of 25 μm, and a cover film was attached thereon to obtain a dry film. Thereafter, the cover film was peeled off, and the film was bonded to a patterned copper foil substrate by thermal lamination, followed by exposure by the exposure method listed in Table 2. Thereafter, after removing the carrier film, it was developed with a 1% by weight aqueous solution of sodium carbonate for 90 seconds to obtain a pattern, and heat-cured in a hot air dryer at 150° C. for 60 minutes to obtain a test substrate. The undercut evaluation as described above was performed by observing the substrate in cross section, and the results were the same as those obtained in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com