A preparation method of monolithic paper-carbon counter electrode for dye-sensitized solar cells

A technology for solar cells and dye sensitization, which is applied in the field of preparation of monolithic paper charcoal counter electrodes to achieve the effects of avoiding electron loss, avoiding shedding, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

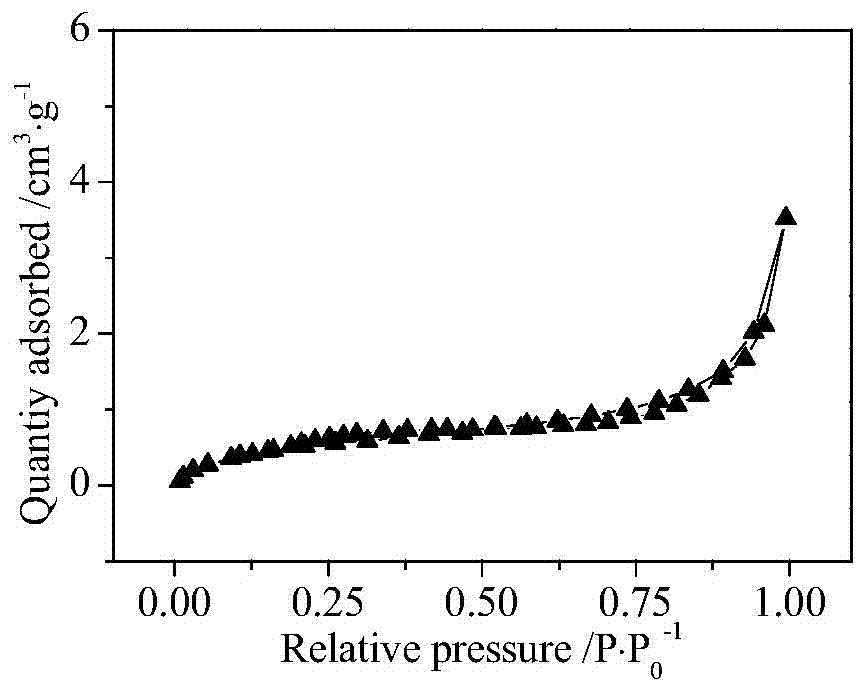

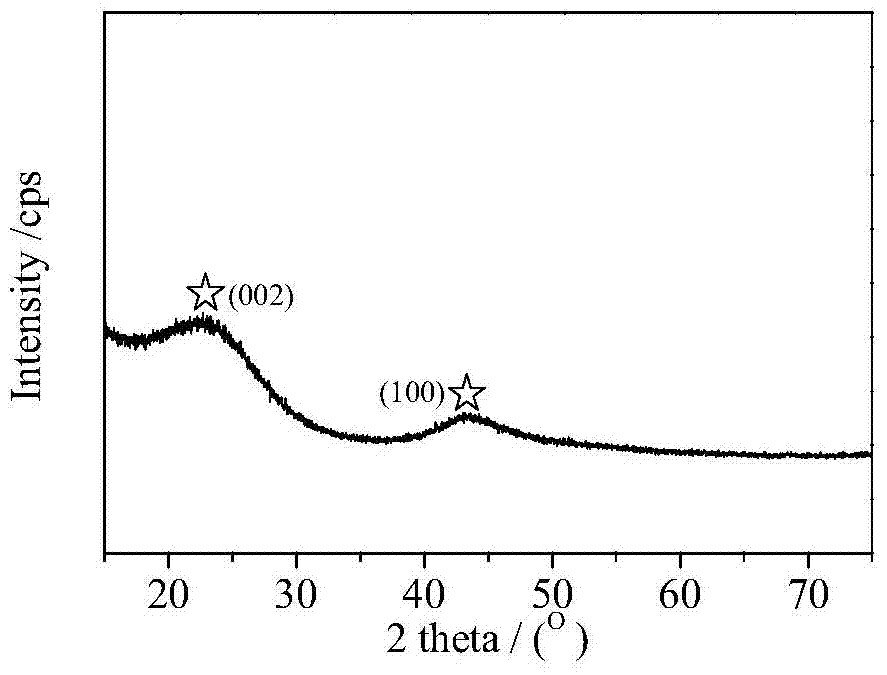

Image

Examples

Embodiment 1

[0035] 1) Film making:

[0036] First, heat the paper from 60°C to 180°C at a rate of 1°C / h and keep it warm for 16 hours; 2 Carry out pyrolysis under protection, specifically: raise the temperature from room temperature to 800 °C at a rate of 1 °C / min and keep it warm for 1 hour. After completing the pyrolysis, cool to room temperature with the furnace to obtain a paper charcoal film.

[0037] 2) Glue matching:

[0038] According to the weight ratio of cellulose: water=1:40, cellulose and water are evenly mixed to obtain cellulose colloid;

[0039] 3) Coating:

[0040] Depositing the cellulose colloid on the conductive substrate by a spin coating method to obtain a thin layer of cellulose colloid covering the conductive substrate;

[0041] 4) Lamination:

[0042] Attaching a paper charcoal film to a thin layer of cellulose colloid on a conductive substrate;

[0043] 5) Drying:

[0044] The coated conductive substrate was dried in an air atmosphere at 180° C. for 0.5 h t...

Embodiment 2

[0054] 1) Film making:

[0055] First, heat the paper from 60°C to 160°C at a rate of 1°C / h and keep it warm for 32 hours; 2 Carry out pyrolysis under protection, specifically: raise the temperature from room temperature to 700 °C at a rate of 1 °C / min and keep it warm for 1 hour. After completing the pyrolysis, cool to room temperature with the furnace to obtain a paper charcoal film.

[0056] 2) Glue matching:

[0057] According to the weight ratio of cellulose: water=1:90, cellulose and water are evenly mixed to obtain cellulose colloid;

[0058] 3) Coating:

[0059] Depositing the cellulose colloid on the conductive substrate by spraying to obtain a thin layer of cellulose colloid covered on the conductive substrate;

[0060] 4) Lamination:

[0061] Attaching a paper charcoal film to a thin layer of cellulose colloid on a conductive substrate;

[0062] 5) Drying:

[0063] The coated conductive substrate was dried at 120° C. for 1 h in an air atmosphere to obtain a mo...

Embodiment 3

[0072] 1) Film making:

[0073] First, heat the paper from 60°C to 170°C at a rate of 1°C / h and keep it warm for 23 hours; 2 Carry out pyrolysis under protection, specifically: raise the temperature from room temperature to 1000°C at a rate of 1°C / min and keep it warm for 0.5h. After completing the pyrolysis, cool to room temperature with the furnace to obtain a paper charcoal film.

[0074] 2) Glue matching:

[0075] By cellulose: the weight ratio of water=1:65, cellulose and water are uniformly mixed, obtain cellulose colloid;

[0076] 3) Coating:

[0077] Depositing the cellulose colloid on the conductive substrate by spraying to obtain a thin layer of cellulose colloid covered on the conductive substrate;

[0078] 4) Lamination:

[0079] Attaching a paper charcoal film to a thin layer of cellulose colloid on a conductive substrate;

[0080] 5) Drying:

[0081] The coated conductive substrate was dried at 80° C. for 2 h in an air atmosphere to obtain a monolithic pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com