Gearbox and 2KW motor integrated system applied to low-speed electric vehicle

A gearbox, 2KW technology, applied in the field of electric vehicles, can solve the problems of increasing the overall size, increasing the manufacturing cost, abnormal connection noise, etc., and achieving the effect of reducing the overall size, low operating noise, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

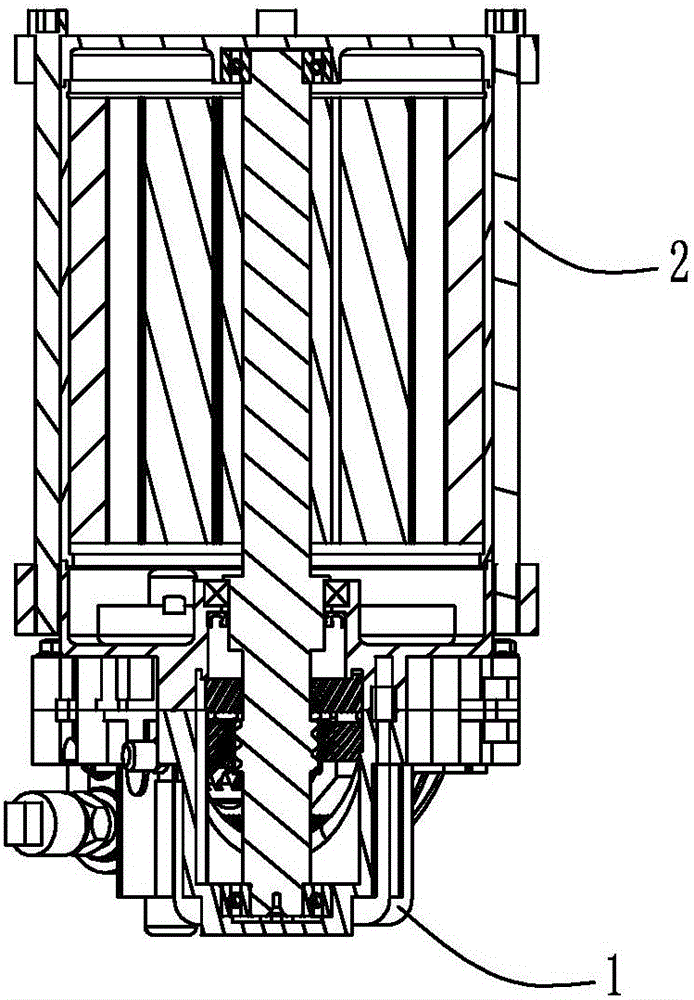

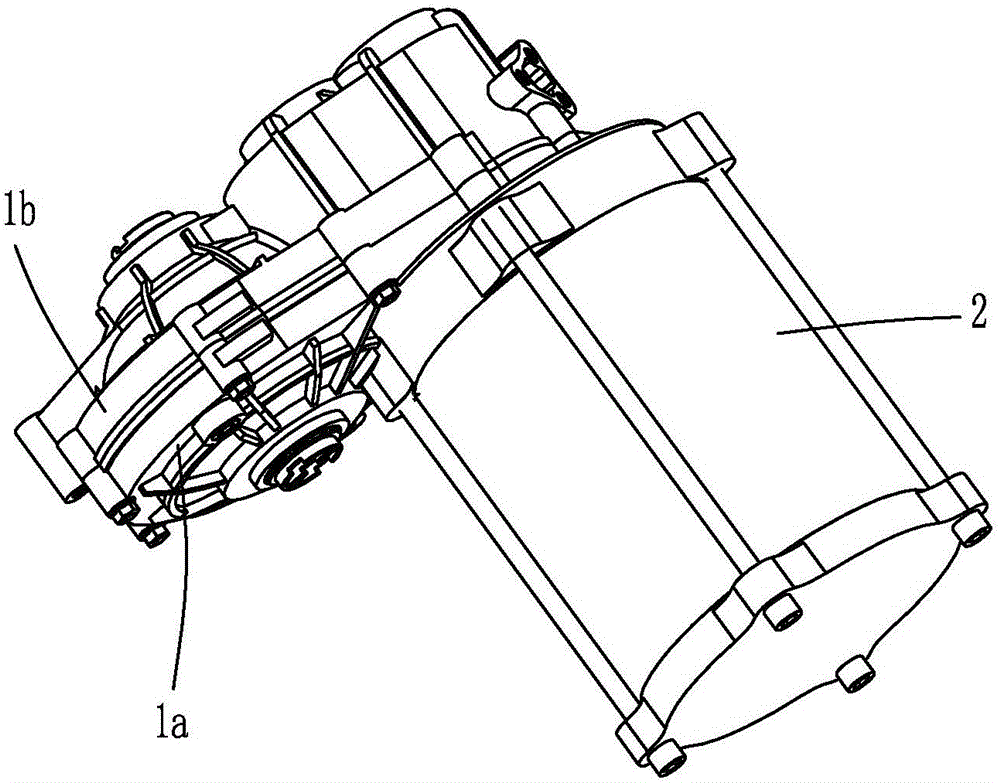

[0015] combine figure 1 — figure 2 The gearbox and 2KW motor integrated system suitable for low-speed electric vehicles shown is composed of two parts: gearbox 1 and 2KW permanent magnet reluctance motor 2.

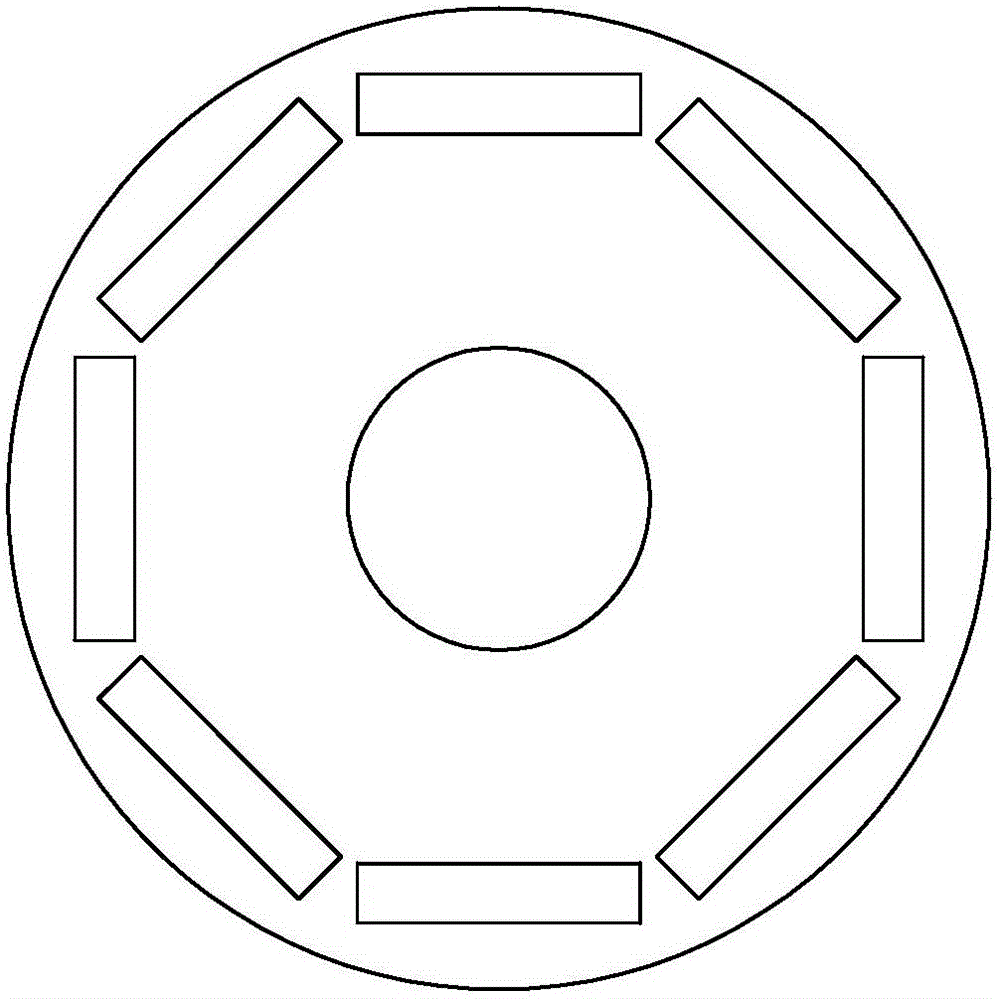

[0016] The casing of the gearbox 1 is locked together by bolts and nuts after the case cover 1a and the case body 1b are fastened together. The stator and rotor of the permanent magnet reluctance motor 2 are made of laminated silicon steel sheets, such as image 3 As shown, the rotor is embedded with uniformly distributed magnetic steel on the circumference. The torque of the permanent magnet reluctance motor 2 is the sum of the reluctance torque and the magnet torque, and the motor efficiency can reach 95%.

[0017] The motor shaft of the permanent magnet reluctance motor 2 and the power input shaft of the gearbox 1 share ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com