Control device for internal combustion engine

A technology of a control device and an internal combustion engine, applied in engine control, internal combustion piston engine, electrical control, etc., can solve problems such as difficulty in allowing the wastegate valve to open, increase air pressure, etc., and achieve the effect of improving fuel efficiency and reducing pumping loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described based on the drawings.

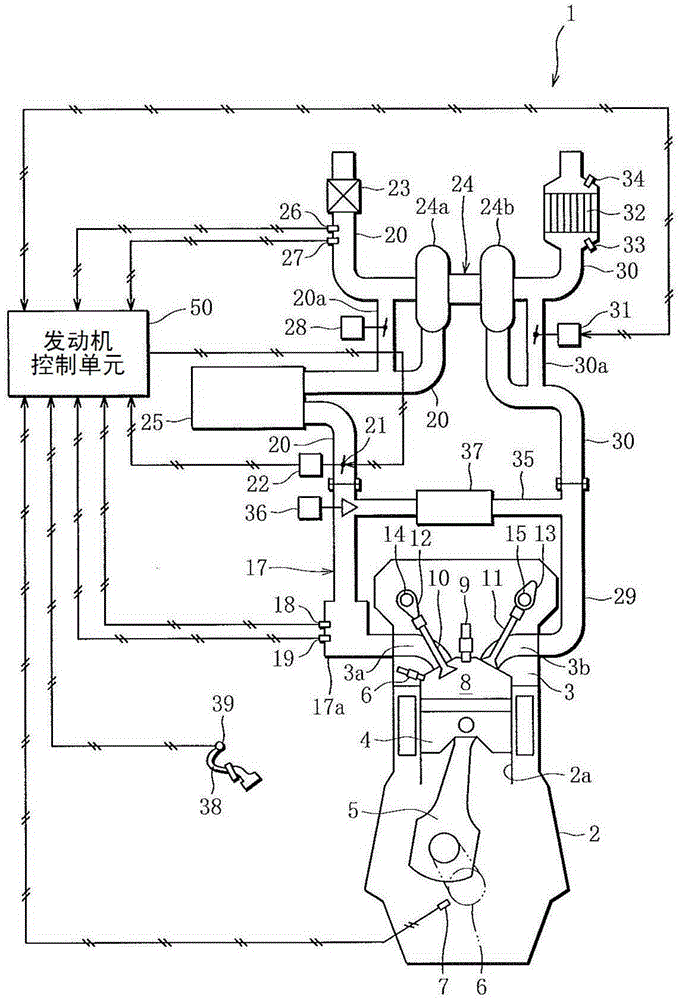

[0032] figure 1 is a schematic diagram of a direct injection gasoline engine to which a control device for an internal combustion engine is applied (hereinafter referred to as engine 1 ) (internal combustion engine).

[0033] Such as figure 1 As shown, the engine 1 is a direct-injection four-stroke in-line four-cylinder gasoline engine in which fuel is injected into the combustion chamber 8 from a fuel injection valve 16 provided in the cylinder head 3 . figure 1 A longitudinal section of a cylinder of engine 1 is shown. Since the other cylinders are considered to have the same structure, they are not shown and there is no repeated description for them.

[0034] Such as figure 1 As shown, the engine 1 consists of a cylinder block 2 on which a cylinder head 3 is mounted.

[0035] The cylinder block 2 is provided with cylinders 2a. In the cylinder 2a, a piston 4 is verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com