Preparation method of SrTiO3-TiO2 porous microsphere photocatalyst

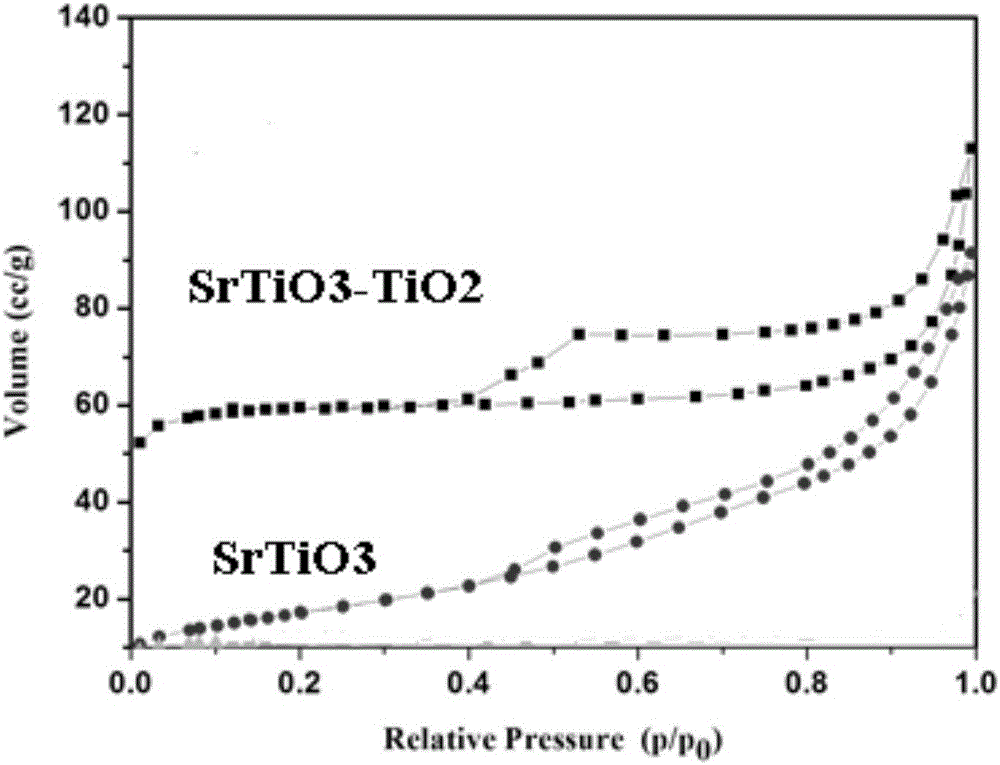

A technology of porous microspheres and composites, applied in chemical instruments and methods, hydrogen production, physical/chemical process catalysts, etc., can solve the problems of uneven shape and size, few active sites, small specific surface area, etc., to achieve The test method is simple and easy, the photocatalytic activity is enhanced, and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Dissolving titanium source: Dissolve a certain amount of titanium source in a certain amount of ethanol, add a certain amount of glycerin to the solution, and stir for 0.5 hours to form a uniform and transparent solution.

[0030] 2. Hydrothermal reaction: The transparent solution in the first step is subjected to a hydrothermal reaction at a certain temperature for a certain period of time to obtain a precipitate.

[0031] 3. Dissolving the strontium source: Dissolve a certain amount of strontium source in a certain amount of ethanol solution, add a certain amount of glycerol to the solution, and stir until a homogeneous solution is formed.

[0032] 4. Add the precipitate obtained in step 2 to the solution in step 3.

[0033] 5. Hydrothermal reaction, the solution obtained in step 4 is subjected to a hydrothermal reaction at a certain temperature for a certain period of time.

[0034] 6. Separation, washing and drying: the precipitate obtained in step 5 is washed w...

Embodiment 2

[0038] The difference between this embodiment and the specific embodiment 1 is that the titanium source described in step 1 is tetrabutyl titanate. Others are the same as in Example 1.

Embodiment 3

[0040] The difference between this embodiment and Embodiments 1 to 2 is that the reaction temperature of the hydrothermal reaction described in step 2 is 180° C., and the reaction time is 1 h to 24 h. Others are the same as in Examples 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com