Preparation method of cobalt-zinc oxide composite catalyst

A technology of composite catalyst and zinc oxide, which is applied in the field of preparation of cobalt-zinc oxide composite catalyst, can solve problems such as ecological environment and human health hazards, and achieve stable performance, strong market application prospects, and strong absorption and catalytic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

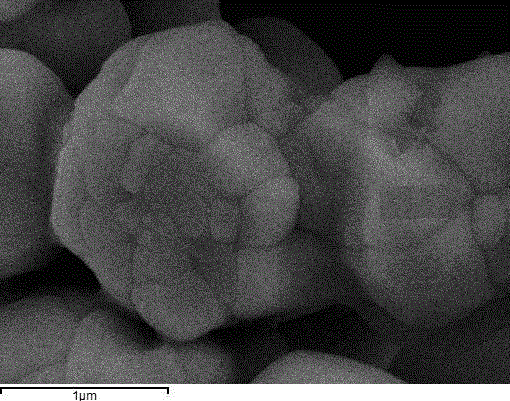

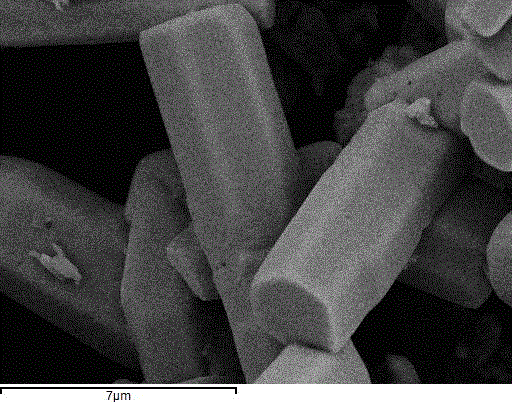

Image

Examples

Embodiment 1

[0012] (1) Take 2.5891g ZnCl 2 Dissolve in 30mL deionized water, and wait for complete dissolution to obtain ZnCl 2 solution; (2) Add 15g of glucose to hot ZnCl at one time 2 solution, stir while adding to make it dissolve rapidly, and obtain solution X; (3) add 0.2811g CoSO to the heated solution X at one time 4 ?7H 2 O, stir while adding, continue heating to evaporate water, and obtain a brown-black solid; (4) Put the brown-black solid in a drying oven at 100°C for 8 hours, transfer it to an evaporating dish and place it in a calcination box at 600°C for 4 hours. A cobalt-zinc oxide composite catalyst with a cobalt mass content of 5% was prepared. 0.01g cobalt-zinc oxide composite catalyst 15min to 25mg L -1 The degradation efficiency of rhodamine B dye wastewater was 10.42%.

Embodiment 2

[0014] (1) Take 4.4067g ZnCl 2 Dissolve in 30mL deionized water, and wait for complete dissolution to obtain ZnCl 2 solution; (2) Add 15g of glucose to hot ZnCl at one time 2 solution, stir while adding to make it dissolve rapidly, and obtain solution X; (3) add 0.2811g CoSO to the heated solution X at one time 4 ?7H 2 O, stir while adding, continue heating to evaporate water, and obtain a brown-black solid; (4) Put the brown-black solid in a drying oven at 100°C for 8 hours, transfer it to an evaporating dish and place it in a calcination box at 600°C for 4 hours. A cobalt-zinc oxide composite catalyst with a cobalt mass content of 3% was obtained. 0.01mol·L under normal room temperature -1 In the oxidation system composed of Oxone solution and 0.005g cobalt-zinc oxide composite catalyst, 13min to 25mg·L -1 The degradation efficiency of rhodamine B dye wastewater was 94.5%.

Embodiment 3

[0016] (1) Take 2.5891g ZnCl 2 Dissolve in 30mL deionized water, and wait for complete dissolution to obtain ZnCl 2 solution; (2) Add 15g of glucose to hot ZnCl at one time 2 solution, stir while adding to make it dissolve rapidly, and obtain solution X; (3) add 0.2811g CoSO to the heated solution X at one time 4 ?7H 2 O, stir while adding, continue heating to evaporate water, and obtain a brown-black solid; (4) Put the brown-black solid in a drying oven at 100°C for 8 hours, transfer it to an evaporating dish and place it in a calcination box at 600°C for 4 hours. A cobalt-zinc oxide composite catalyst with a cobalt mass content of 5% was obtained. 0.01mol·L under normal room temperature -1 In the oxidation system composed of Oxone solution and 0.005g cobalt-zinc oxide composite catalyst, 13min to 25mg·L -1 The degradation efficiency of rhodamine B dye wastewater was 99.58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com