Polysaccharide-peptide and liposome thereof

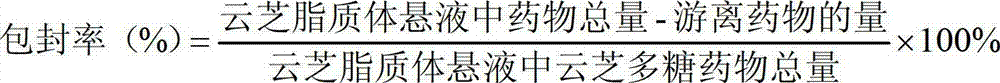

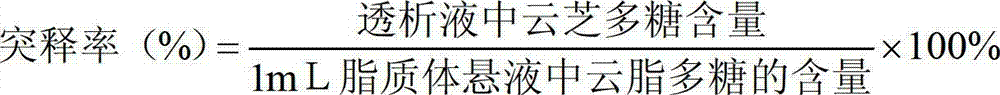

A Yunzhi glycopeptide and liposome technology, applied in the directions of liposome delivery, peptide/protein components, non-central analgesics, etc., can solve the problem of unsafe increase in production, poor water solubility of polysaccharides, and low biological activity of polysaccharides, etc. problem, to achieve excellent encapsulation rate and burst release rate, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Purified versicolor glycopeptide bulk drug

[0036]1. Source of Yunzhi fermentation broth: Trametes versicolor (Yunzhi), Trametes, preservation number CGMCC 5.161 provided by China General Microorganism Culture Collection and Management Center, the strain was transferred to slant medium for conventional culture at 26-28°C for 7 days, Get the activated Yunzhi bacterial strain; inoculate the activated Yunzhi bacterial strain on the seed medium, wherein the seed medium consists of 6% glucose, 4% yeast powder, 5% peptone, 0.2% potassium dihydrogen phosphate, and 0.02% magnesium sulfate , defoaming agent 0.1%, prepared with water, pH value is natural, 26 ~ 28 ℃ shaking culture for 3 days to obtain the first-class seed liquid of Versicolor versicolor; the first-class seed liquid is inserted into the second-level seed medium, and the second-level seed medium consists of 4% glucose, 4% yeast powder, 4% peptone, 0.2% potassium dihydrogen phosphate, 0.02% magnesium sul...

Embodiment 2

[0039] Example 2: Purified versicolor glycopeptide bulk drug

[0040] After the Yunzhi mycelium prepared according to the method of Example 1 was pulverized, 10 times the amount of purified water was added, and the water extract of Yunzhi was prepared by incubating at 95-100°C for 5 hours; the water extract of Yunzhi was micro-filtered, The membrane material used in the filtration is a ceramic membrane with a molecular weight cut-off of 400,000 Daltons. The working temperature of the microfiltration membrane is 45°C, and the working pressure: the inlet pressure is 4.0bar, and the outlet pressure is 3.0bar; the microfiltrate is taken according to 2: Add chloroform: n-butanol (volume ratio 4:1) mixture solution at a ratio of 1, shake vigorously to remove free protein, centrifuge to take the upper layer, repeat 10 times; remove the organic solvent under reduced pressure at 40°C.

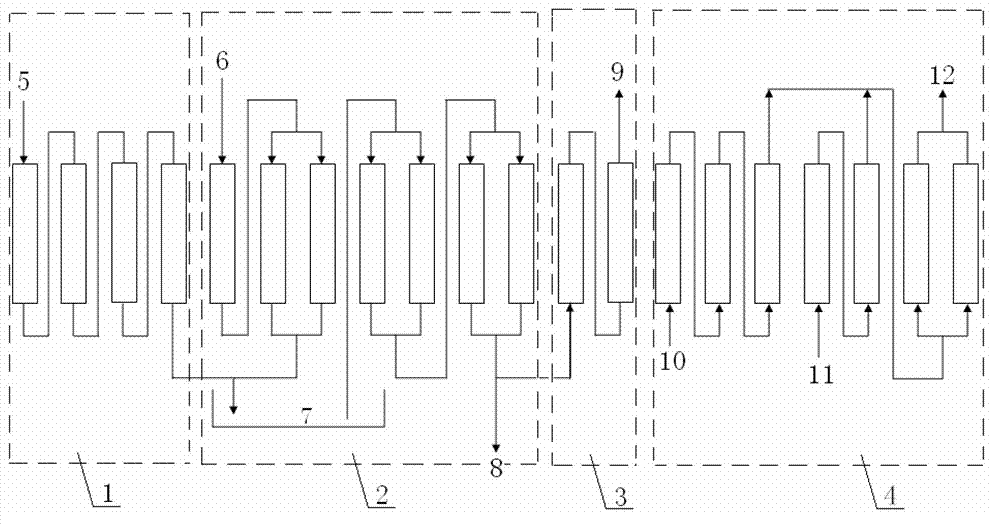

[0041] For the deproteinized Yunzhi water extract, the simulated moving bed separation system is use...

Embodiment 3

[0042] Example 3: Purified versicolor glycopeptide bulk drug

[0043] Take the Yunzhi mycelia prepared according to the method of Example 1, add 10 times the amount of purified water, and keep warm at 95-100°C for 4 hours to prepare the Yunzhi water extract; the Yunzhi water extract is subjected to microfiltration, and the microfiltration The membrane material used is a ceramic membrane with a molecular weight cut-off of 450,000 Daltons. The working temperature of the microfiltration membrane is 40°C, and the working pressure: the inlet pressure is 4.0bar, and the outlet pressure is 3.0bar;

[0044] Take the microfiltrate, add chloroform:n-butanol (volume ratio 4:1) mixed solution according to the ratio of 2:1, shake vigorously to remove free protein, centrifuge to take the upper layer, repeat 10 times; remove the organic solvent under reduced pressure at 40°C .

[0045] For the deproteinized Yunzhi water extract, the simulated moving bed separation system StarSep-30025 was u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com