Rotary type galvanometer scanning device and application method thereof

A galvanometer scanning and rotating device technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high technical content, high cost, increased hardware control and software complexity, etc., to overcome the limitation of working space , expanding the scope of work, avoiding the effect of system complexity and hardware cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

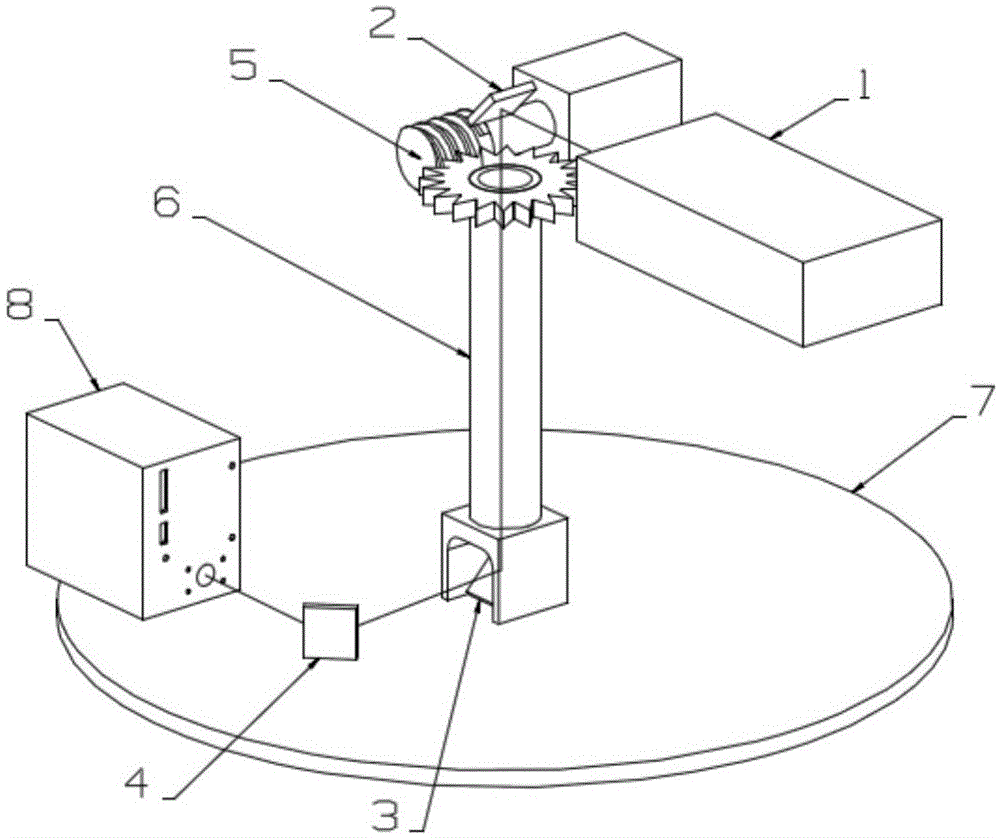

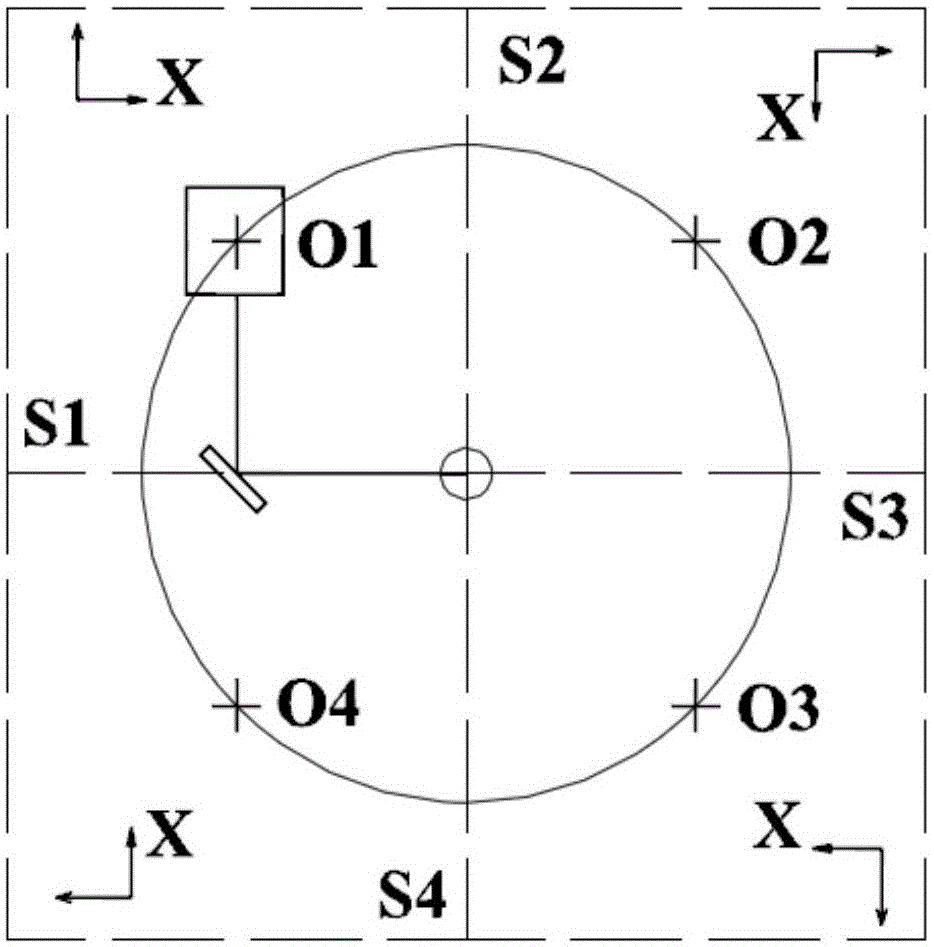

[0016] Such as figure 1 As shown, a rotary galvanometer scanning device provided by the present invention includes a laser 1 , laser propagation devices 2 , 3 , 4 , a rotating device 5 , a rotating shaft 6 , a turntable 7 and a scanning galvanometer 8 .

[0017] The turntable 7 is disc-shaped, the scanning vibrating mirror 8 is installed on the turntable 7, the first end of the rotating shaft 6 is connected to the center of one side of the turning table 7, and the rotating device 5 drives the rotating shaft 6 to rotate, so that the scanning vibrating mirror 8 follows the turntable 7 Turn together to change its working position. The laser light emitted by the laser 1 is reflected by the laser propagation devices 2 , 3 , 4 and the scanning galvanometer 8 , and irradiates the working surface below the scanning galvanometer 8 .

[0018] The rotating device 5 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com