Straight barrel and straight paddle type peeling and crushing device for mulberry twigs with branches

A crushing device and fork branch technology, applied in bark, wood processing equipment, manufacturing tools, etc., can solve the problems of high cost, easy hand injury, low efficiency, etc., and achieve the effect of improving work efficiency and reducing human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with accompanying drawing, the present invention is described in further detail.

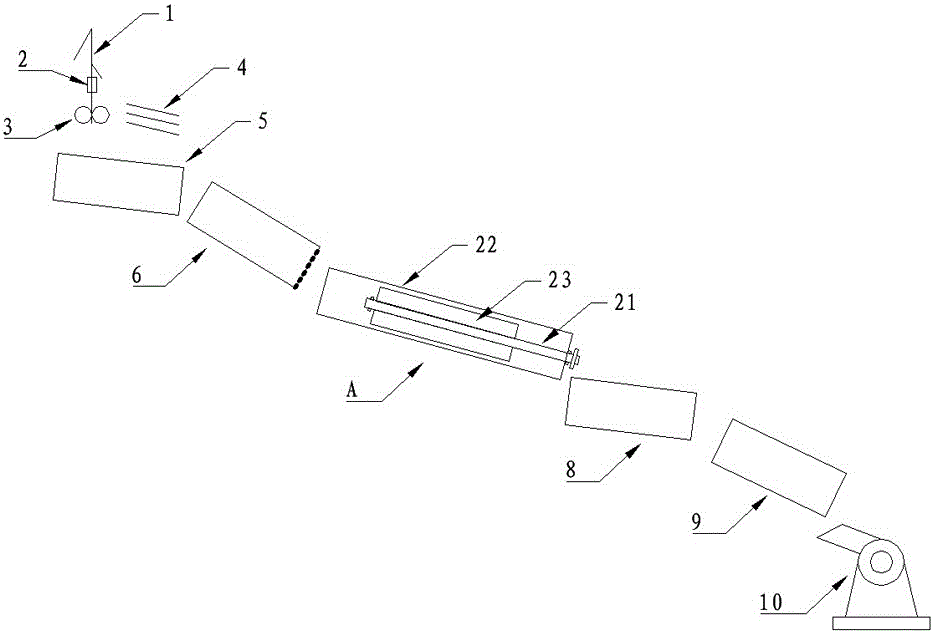

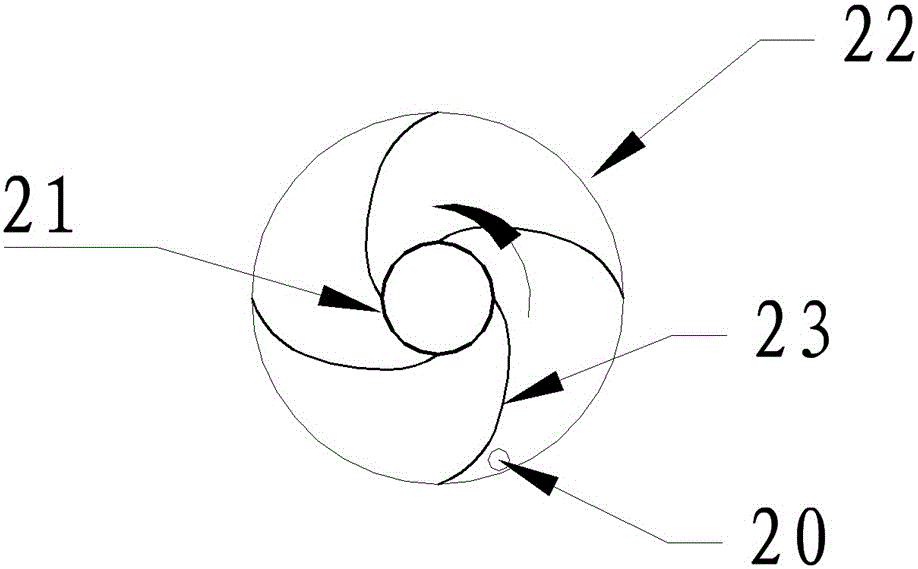

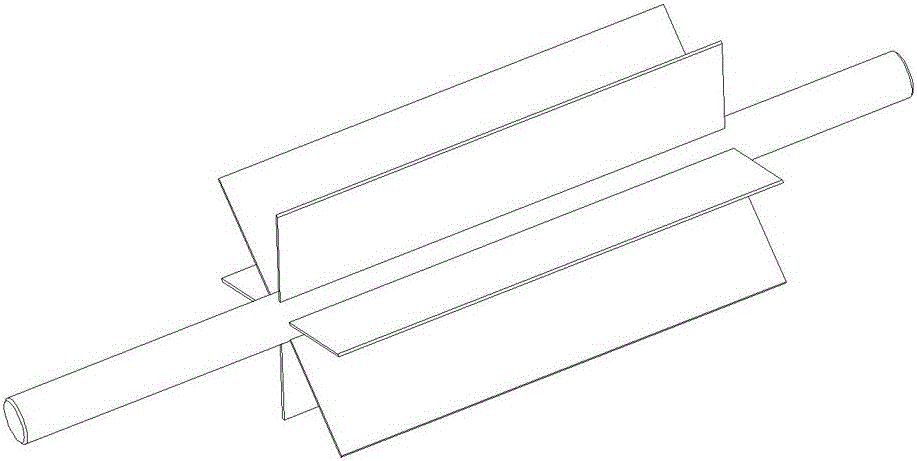

[0025] Such as figure 1 , figure 2 and image 3 The shown straight cylinder straight paddle type peeling and crushing device for mulberry branches with forked branches includes a forked branch remover, a peeler A and a pulverizer 10. The forked branch remover is composed of a ring knife 2 and two relatively rotating rollers 3. The mulberry branch 1 of the branch is inserted into the ring knife 2, and is pressed and dragged by the relatively rotating roller 3 to realize the cutting and separation of the branch by the ring knife 2; The rotating shaft 21 with paddle 23 forms, and paddle 23 has elasticity and paddle 23 outer diameter is slightly larger than straight tube 22 internal diameters, and paddle 23 is flat cuboid shape and vertically implants rotating shaft 21; The core is connected to the shredder 10 .

[0026] A shaking table 5 and a feeding drum 6 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com