Metal ceramic thermal calendar forming mold control system based on optical fiber grating sensor and operating method thereof

A fiber grating and cermet technology, which is applied in the field of plastic surface molding, can solve the problems of increased production cost, increased production cost and energy consumption, lack of supporting control system, etc., and achieve the effect of stable and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

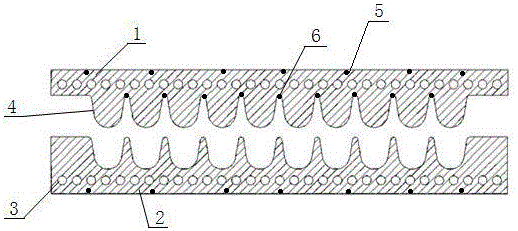

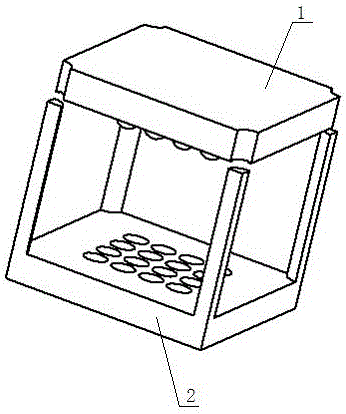

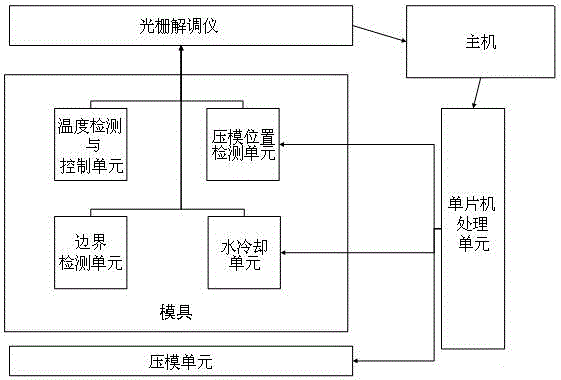

[0016] Such as figure 1 , 2 , 3, the present embodiment provides a control system for a cermet thermal calendering mold based on a fiber grating sensor, the mold is made of a cermet heating material, and the control system includes a die position detection unit, a water cooling unit , a temperature detection and control unit, a die pressing unit, a boundary detection unit, a single-chip processing unit, and a host, the single-chip processing unit is connected to the host, and the mold is a pair of male mold 1 and female mold 2 that fit in shape, male mold 1 Water injection through holes 3 are evenly distributed on the master mold 2, and the water cooling unit is composed of a water pump for controlling water injection and a water outlet pipe connected with the water injection through hole 3. The control end of the water pump is connected with the singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com