Perfume pump with external spring

A perfume and special-shaped spring technology, which is applied in the direction of spraying devices, packaged food, packaged items, etc., can solve the problems of poor stability of nozzle liquid output, difficulty in fixed use of nozzles, etc., and achieve good sealing, reasonable structural design, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

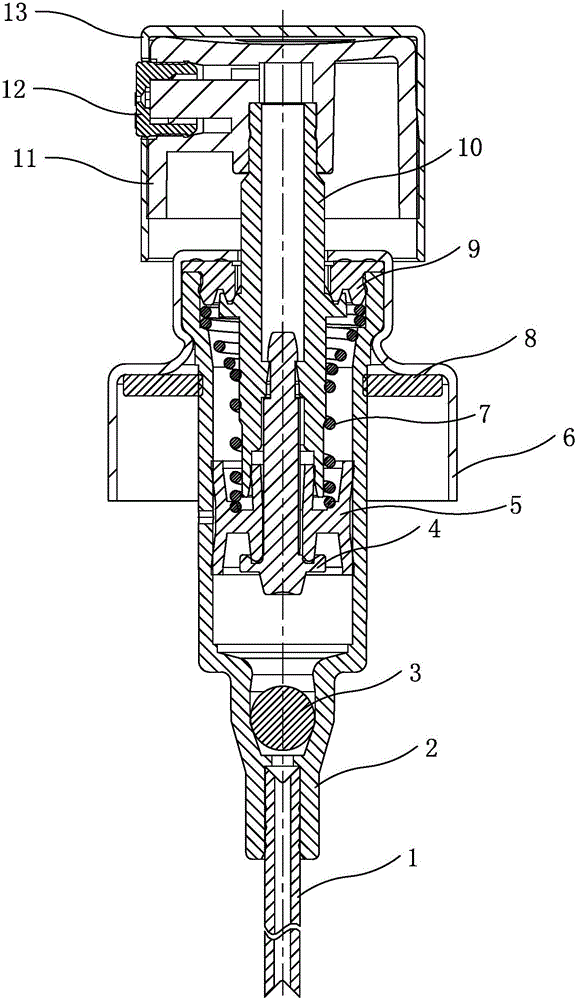

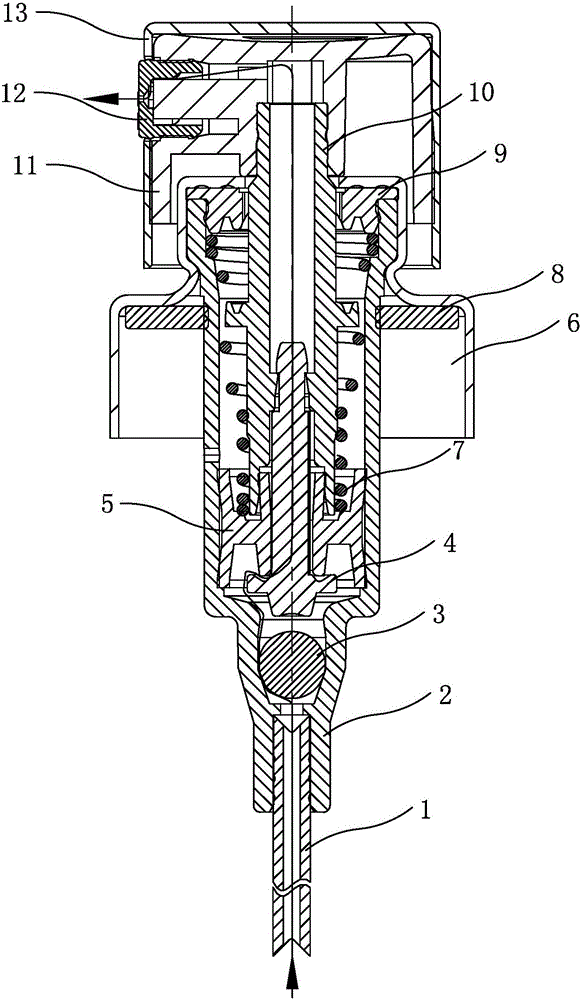

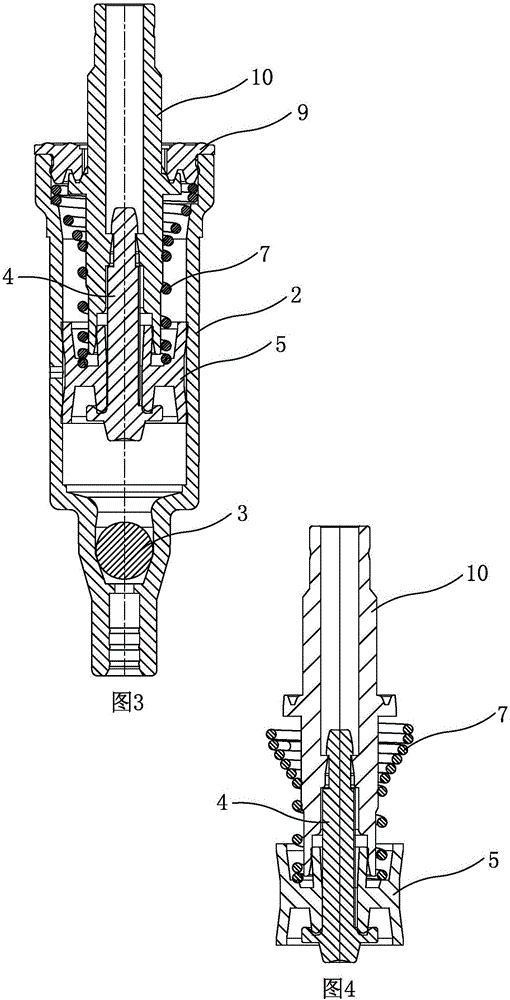

[0022] Now in conjunction with the accompanying drawings, the structure of the present invention will be further described. Such as Figure 1 to Figure 7 As shown, the perfume pump includes a straw 1, a pump body 2, a glass ball 3, a valve needle 4, a piston 5, an alumina bayonet 6, a special-shaped spring 7, a gasket 8, an inner plug 9, a valve stem 10, and a head cap 11 , Spray sheet 12, alumina press cap 13, valve needle, piston, special-shaped spring, valve stem form a valve needle assembly, valve needle assembly, pump body, glass ball, inner plug form a pump body assembly, alumina press cap, spray sheet Together with the head cap, the pump head assembly is composed. The glass ball is set in the liquid inlet hole at one end of the pump body, and the glass ball cooperates and seals with the inclined surface at the liquid inlet hole of the pump body, and is fixed by the buckle point to control the movable stroke distance of the glass ball. The special-shaped spring is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com