Structure of pure oxygen generation assembly and micro-oxygen therapeutic instrument comprising pure oxygen generation assembly

A component and pure oxygen technology, applied in physical therapy, electrolytic components, bathing devices, etc., can solve the problems of accelerating electrochemical corrosion of components, reducing the service life of components, and increasing contact resistance, so as to slow down electrochemical corrosion and avoid using Hidden dangers, the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

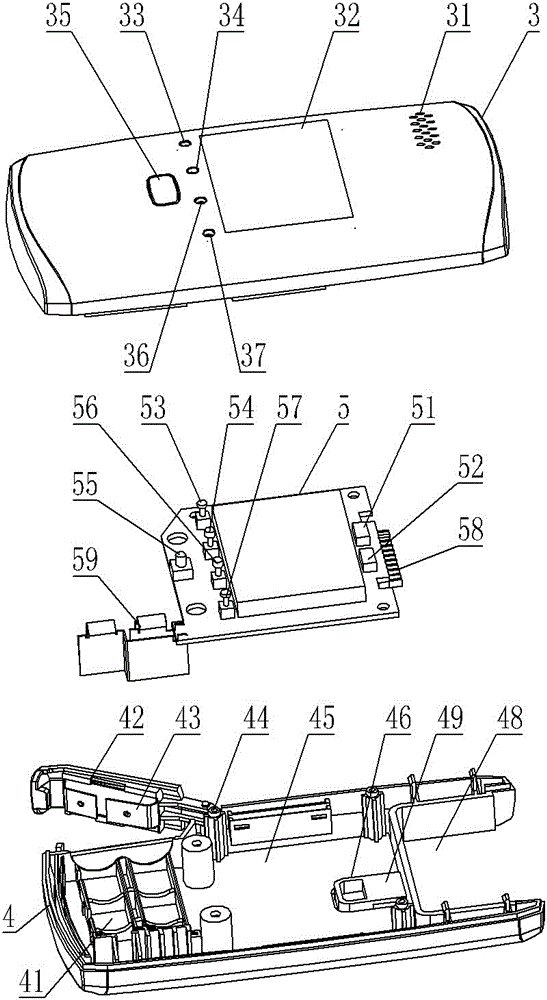

[0033] Such as Figure 5 to Figure 8 As shown, a structure of a pure oxygen generating assembly includes a gas end plate 82, a membrane electrode assembly 84, an oxygen end plate 85 and a gas collecting base 86. The membrane electrode assembly 84 includes an anode gas diffusion layer 846, an anode catalyst layer 845, and a proton Exchange membrane 843, cathode catalyst layer 842, cathode gas diffusion layer 841, gas end plate 82, cathode gas diffusion layer 841, cathode gas catalyst layer 842, proton exchange membrane 843, anode gas catalyst layer 845, anode gas diffusion layer 846, oxygen The end plate 85 and the gas collecting base 86 are stacked in sequence and tightly wound into a whole by the insulating tape 81. The gas end plate 82 is a non-porous end plate, and a metal gasket 83 is provided between the gas end plate 82 and the cathode gas diffusion layer 841 The area of the gas end plate 82 and the cathode gas diffusion layer 841 are both larger than the area of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com