Printing color paste containing lac insect pigment and its printing process

A technology of printing color paste and printing technology, which is applied in the fields of dyeing, textiles and papermaking, etc., can solve the problems of lack of printing application research, and achieve good biodegradability, good stability, and strong coloring power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

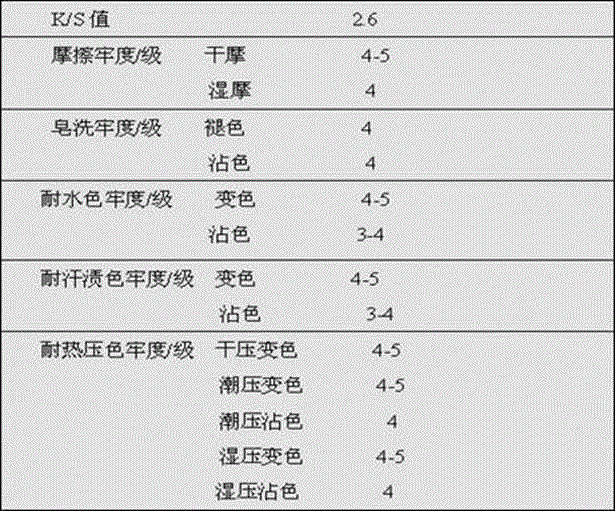

Embodiment 1

[0032] The printing paste that contains lac insect pigment of the present embodiment is to the printing process of cotton fabric, and the steps are as follows:

[0033] Print the cotton fabric with a printing paste containing 65% of 8% starch paste, 2% of lac insect pigment, 2% of urea, 1% of lanthanum chloride, and 30% of water, then dry at 80°C for 7min, and steam at 102°C. Steam for 15 minutes, and then perform post-processing. The post-processing process includes cold water washing, hot water washing, soap washing, hot water washing, cold water washing, and drying.

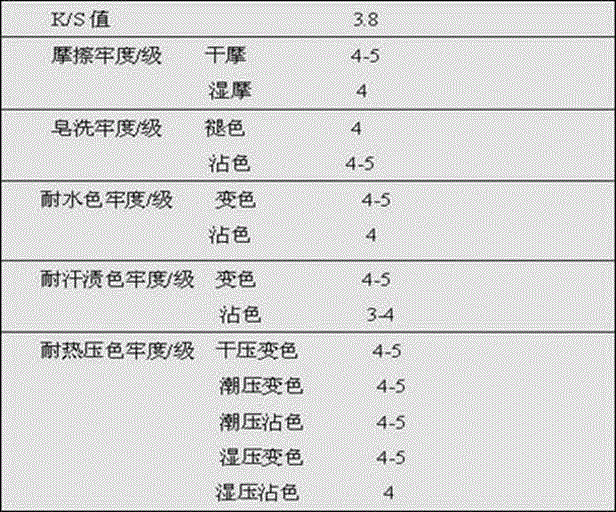

Embodiment 2

[0035] The printing process of the printing paste containing lac worm pigment of the present embodiment to cotton fabrics, the steps are as follows: use 50% of the original paste containing 8% starch, 5% of lac worm pigment, 5% of urea, 4% of zinc sulfate, water 36% printing paste is printed on cotton fabric, then dried at 100°C for 5 minutes, steamed at 102°C for 12 minutes, and then post-treated. The post-treatment process includes cold water washing, hot water washing, soap washing, hot water washing, cold water washing, and drying Dry.

Embodiment 3

[0037] The printing process of the printing paste containing lac worm pigment of the present embodiment to cotton fabrics, the steps are as follows: use 60% of the original paste containing 8% starch, 3% of lac worm pigment, 3% of urea, 2% of cerium chloride, Print the cotton fabric with 32% water printing paste, then dry at 90°C for 6 minutes, steam at 102°C for 10 minutes, and then perform post-treatment. The post-treatment process includes cold water washing, hot water washing, soap washing, hot water washing, cold water washing, drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com