End expanding type anti-floating anchor rod

An anti-floating anchor, large-scale technology, applied in the direction of sheet pile walls, protection devices, buildings, etc., can solve problems such as end rupture, complex design of the anchor head structure, and reduce the pullout resistance of the anchor, so as to expand the spacing and improve the Efficient use of space and shortening the length of the bolt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

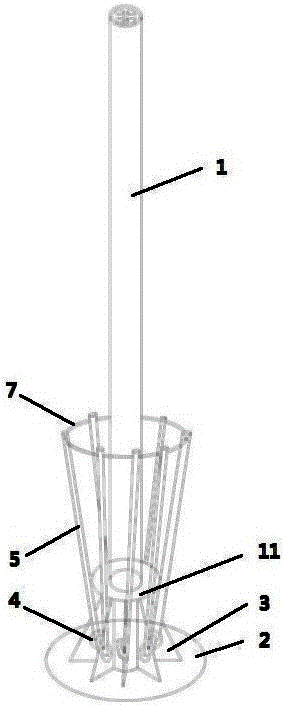

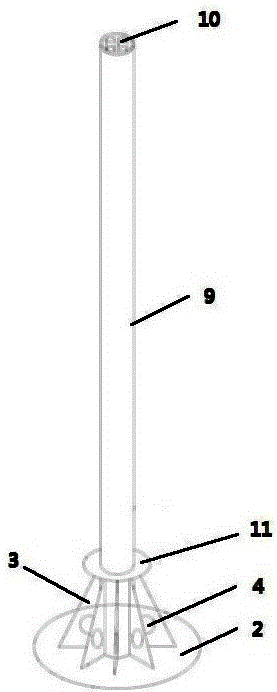

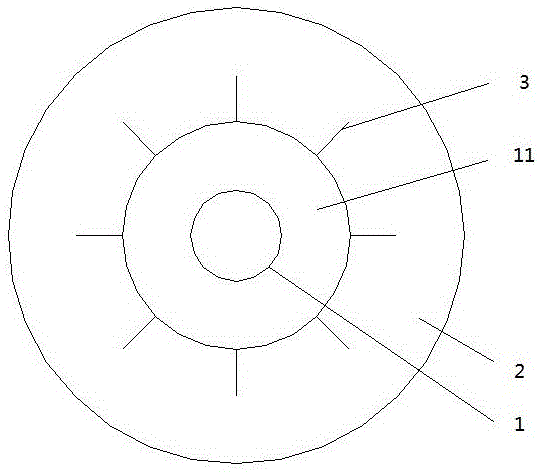

[0026] Such as figure 1 As shown, it is a structural schematic diagram of an embodiment of the end enlarged anti-floating anchor rod of the present invention. The end enlarged anti-floating anchor rod of this embodiment includes an anchor rod 1 and an anchor head arranged at the bottom of the anchor rod 1, and an end enlargement structure is provided on the anchor head. The end enlargement structure of this embodiment includes a bottom plate 2 fixedly connected to the bottom of the anchor rod 1 and a connecting plate 3 arranged uniformly in a ring and welded to the bottom plate 2 and the anchor rod 1 at the same time. The connecting plate 3 is provided with a connecting hole 4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com