Anti-crystallization device of urea nozzle in scr system

A technology of SCR system and urea nozzle, applied in mufflers, exhaust devices, engine components, etc., can solve the problems of poor interchangeability and versatility, high manufacturing cost, complicated manufacturing, etc., to reduce the risk of crystal blockage , Low production and maintenance costs, the effect of simplifying the structure of the mounting support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

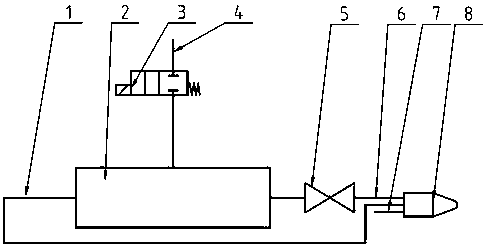

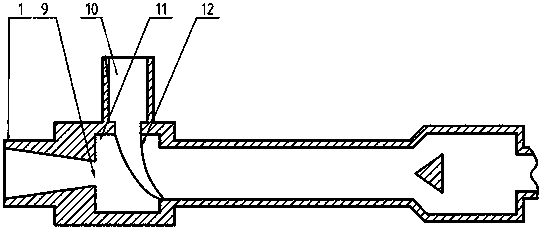

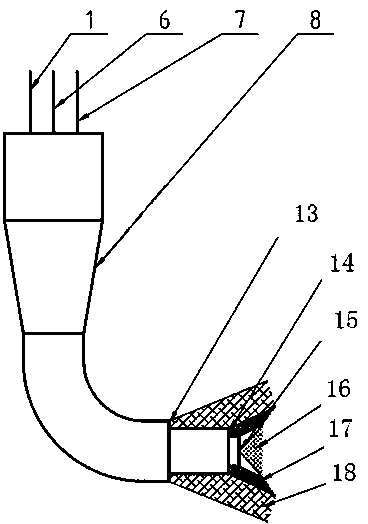

[0016] Embodiment 1, with reference to figure 1 , figure 2 , image 3 , comprising a solenoid valve 3, a vortex tube assembly 2, and a nozzle assembly 8, the air inlet 4 of the vortex tube assembly 2 is provided with a solenoid valve, and one end of the vortex tube assembly 2 passes through the cold air pipeline 1 and the nozzle assembly 8, the other end is connected to the nozzle assembly 8 through the hot gas pipeline 6, the nozzle assembly 8 is also provided with a urea inlet 7, and the end of the nozzle assembly 8 is provided with a urea spout 15, a hot gas spout 13, and a cold air spout 14, The urea nozzle 15 is embedded in the cold air nozzle 14 , and the cold air nozzle 14 is embedded in the hot gas nozzle 13 .

Embodiment 2

[0017] Embodiment 2, the anti-crystallization device of the urea nozzle of the SCR system described in Embodiment 1: the vortex tube assembly includes a vortex chamber 11 and a vortex tube inlet 10, and the vortex chamber 11 is provided with a semi-open cavity, The cavity is an air inlet nozzle 12, and the air inlet nozzle 12 is connected to the air inlet 10 of the vortex tube;

Embodiment 3

[0018] Embodiment 3, the anti-crystallization device of the urea nozzle of the SCR system described in Embodiment 1: the hot gas pipeline 6 is provided with an electric control valve 5 for adjusting the output of hot gas;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com