Surface hydrophobic treatment method of deepsea oil extraction metal member

A composite coating and total mass technology, applied to special surfaces, devices for coating liquids on surfaces, coatings, etc., can solve problems such as unreported, and achieve the effects of improving transportation efficiency, reducing losses, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

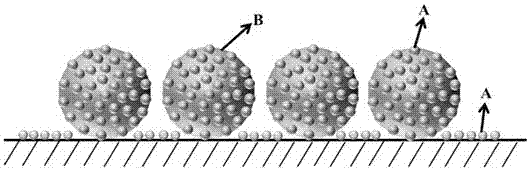

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Fluorine-containing acrylic resin coating:

[0025] The monomers (including methyl methacrylate, butyl acrylate, β-hydroxypropyl methacrylate, dodecafluoroheptyl acrylate) and the initiator benzoyl peroxide (addition amount of 1 0.8% of the total body mass) was dissolved in a mixed solvent of xylene and butyl acetate, and added dropwise to the reactor, and the reaction temperature was 120-140°C. After the dropwise addition, continue to keep warm for 160 minutes to make the reaction complete, and obtain the fluorine-containing acrylic resin coating.

Embodiment 2

[0027] Weigh 30g of ZnO powder with particle diameters of 30-80nm and 300-1000nm in total, ultrasonically disperse for 0.5h, and then add silane coupling agent KH550 to modify the ZnO powder; add the ZnO powder modified by KH550 to In 957.6 g of the fluorine-containing acrylic resin paint prepared in Example 1, it was dispersed uniformly. Among them, the added amount of ZnO powder with a particle size of 30-80 nm is 18 g, and the added amount of ZnO powder with a particle size of 300-1000 nm is 12 g.

[0028] Add 212.4 g of additives to the above mixture, stir evenly, and then spray it on the surface of the metal member, and solidify at 200-230°C to form a film with a coating thickness of 200 μm.

[0029] The above-mentioned auxiliary agents include curing agent 156g, defoamer 2.4g, leveling agent 6g and film-forming auxiliary agent 48g. Among them, the curing agent includes one or more of isocyanate, amino resin, and epoxy resin; the defoamer is a silicone defoamer; the leve...

Embodiment 3

[0032] Weigh TiO with a particle size of 30nm and 500nm 2 , SnO 2 A total of 80g of powder was dispersed ultrasonically for 0.5h, and then the silane coupling agent KH550 was added to modify the powder; the TiO modified by KH550 2 and SnO 2 The powder was added to 743 g of the fluorine-containing acrylic resin coating prepared in Example 1 to make it uniformly dispersed. Among them, TiO with a particle size of 30nm 2 and SnO 2 The amount of powder added is 40g in total, TiO with a particle size of 500nm 2 and SnO 2 The addition amount of powder is 40g altogether.

[0033] Add 125g of amino resin curing agent, 2g of BYK-141 defoamer, 5g of acrylic acid leveling agent, and 45g of propylene glycol ethyl ether to the above mixture, stir evenly, spray on the surface of the metal member, and cure at 200-230°C to form a film. The thickness is 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com