Speed reducer for blade electric vehicle

A pure electric vehicle and reducer technology, which is applied in the direction of vehicle gearboxes, transmission boxes, transmission components, etc., can solve the problems of not being able to output low-speed high-torque, etc., and achieve the effect of large carrying capacity, no sense of frustration, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

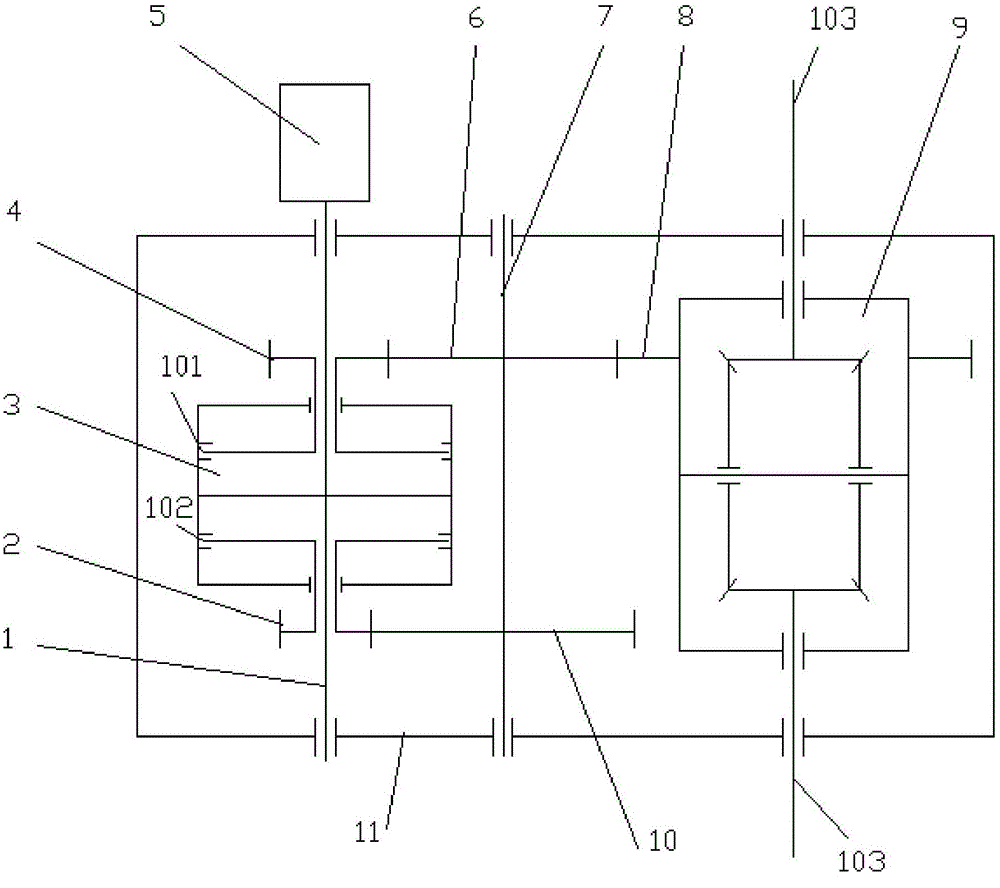

[0019] The reducer for pure electric vehicles provided by the present invention is such as figure 1 Shown, including: input shaft 1, second speed input gear 2, clutch 3, first speed input gear 4, middle first speed gear 6, middle shaft 7, differential transmission gear 8, differential 9, middle second speed gear 10 and shell 11; wherein the shell 11 uses an aluminum alloy shell. The reducer is connected to the motor 5.

[0020] The outer circle of one end of the input shaft 1 is rotatably connected with the housing 11 and connected to the motor 5 in series through the housing 11. The first gear input gear 4, the clutch 3 and the second gear input gear 2 are respectively arranged in the middle of the input shaft 1, and the outer circle of the other end rotates with the housing 11 Connection; the inner hole of the first gear input gear 4 rotates with the input shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com