Calibration method for line-structured light sensor based on mechanical movement and device

A technology of linear structured light and calibration method, applied in the field of measurement, can solve the problems of low precision, complicated methods, and many artificial adjustment links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

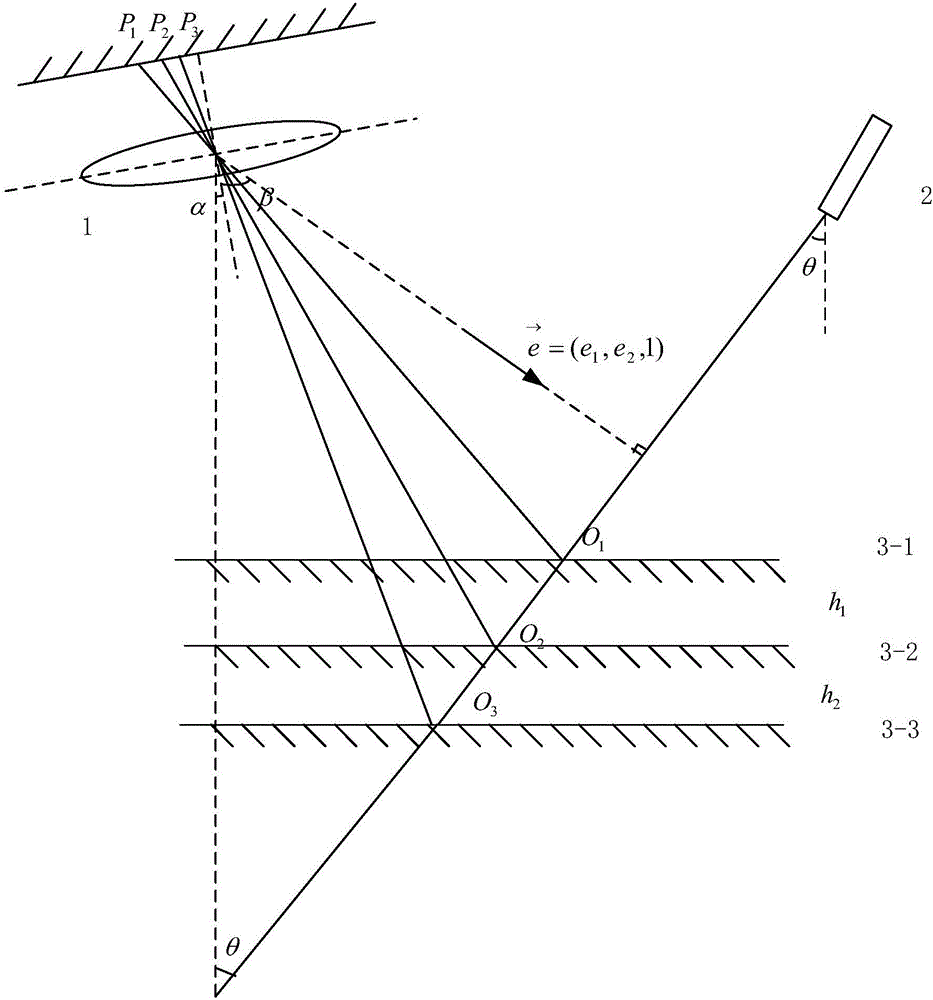

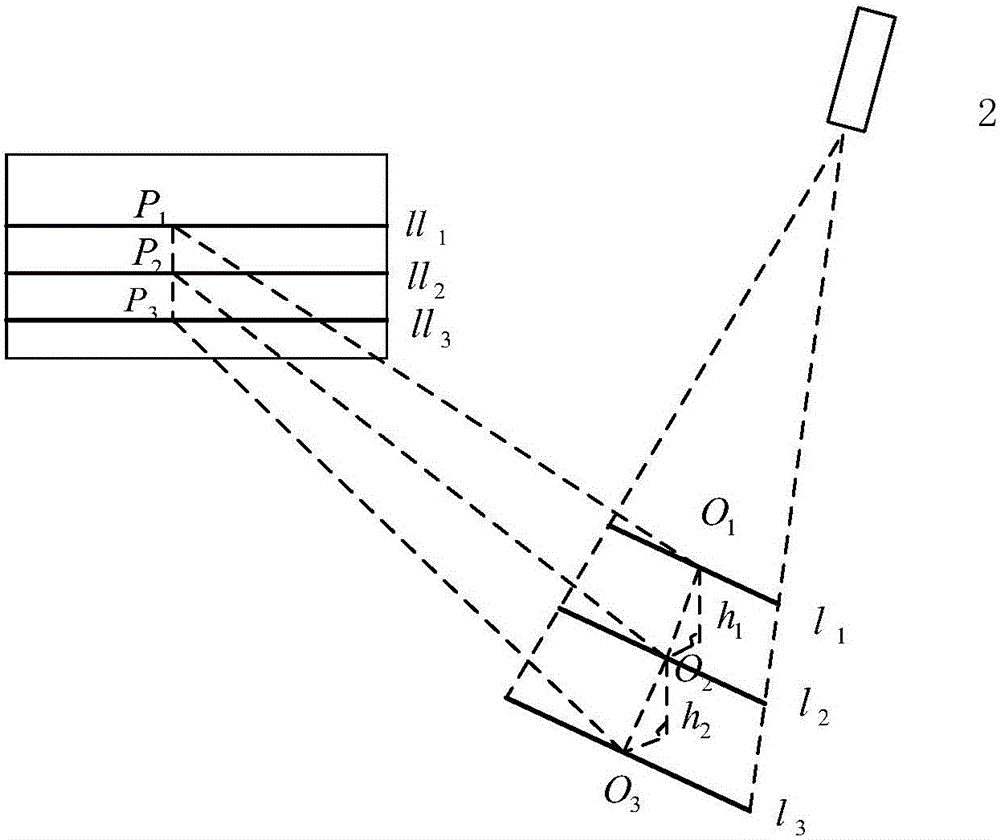

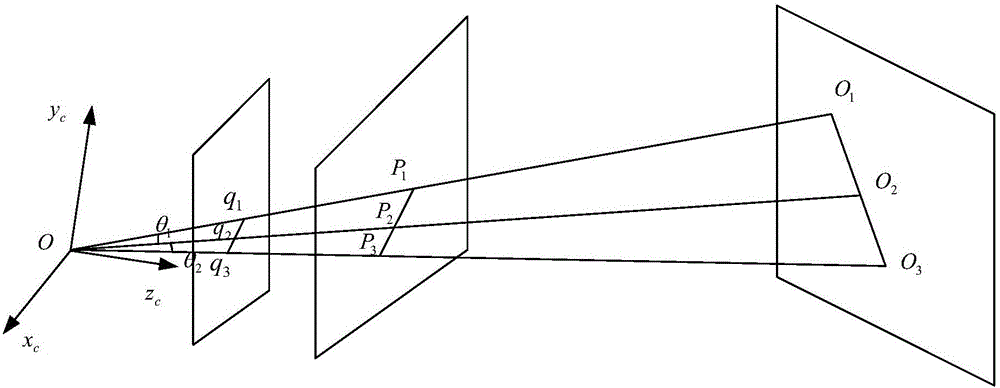

[0041] Embodiment 1 A calibration method of a line structured light sensor based on mechanical motion,

[0042] The device for performing the calibration method described in this embodiment includes a camera 1, a laser 2, a calibration plane 3, and a motion mechanism 4. The camera and the laser are installed on the motion end 41 of the motion mechanism and point to the calibration plane. The motion end can be perpendicular to the calibration plane. The plane direction moves up and down, and the camera and the laser can move synchronously in the direction perpendicular to the calibration plane. The motion mechanism also includes a guide rail 42, an encoder and a servo motor for installing the end of the motion perpendicular to the calibration plane. The camera includes a camera lens, optical filter, laser 2 is a line laser. The schematic diagram of the device is as Figure 5 shown.

[0043] In this example,

[0044] When the end of the movement moves vertically relative to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com