Method for testing temperature difference by surface-mounting temperature measuring element on wall of pipe

A temperature measuring element and pipe wall technology, which is applied in the field of measuring temperature difference by attaching the temperature measuring element to the pipe wall, can solve the problems of unfavorable unit safe operation, large workload, hidden dangers, etc., and achieves small workload and high safety. , The effect of preventing liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

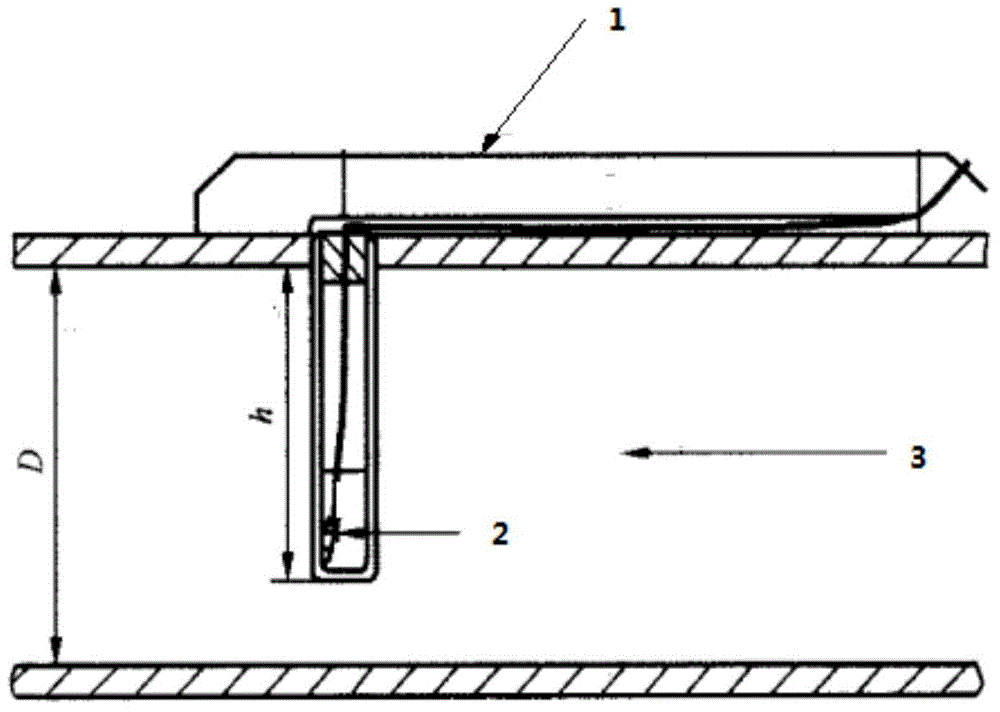

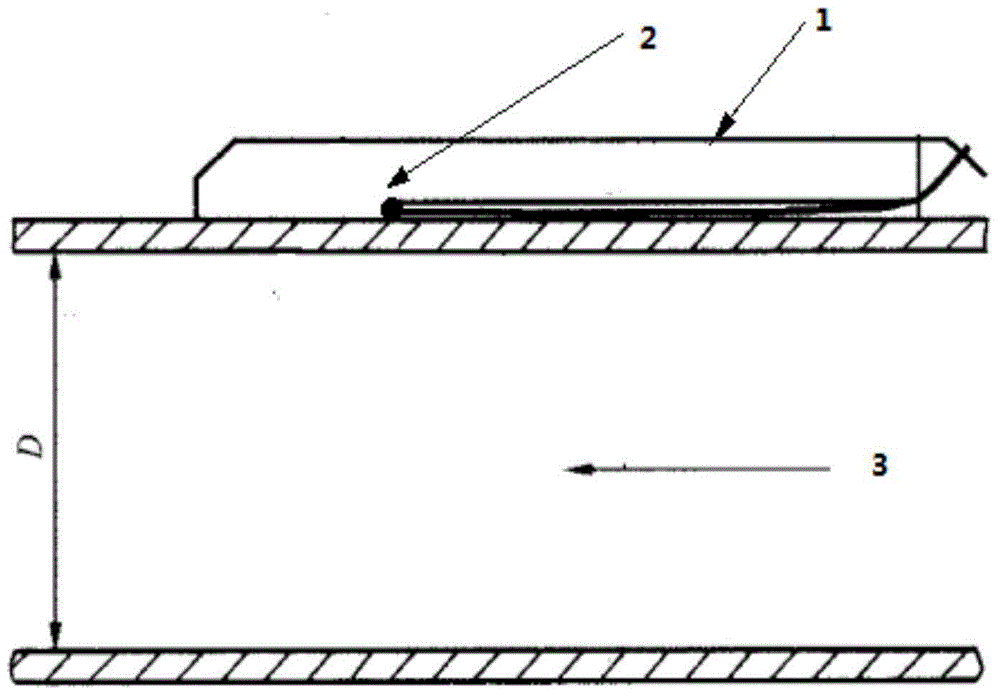

[0048] A method in which the surface of the temperature measuring element is attached to the pipe wall to test the temperature difference:

[0049] In the first step, the material of the inlet and outlet liquid pipes of the cooler is the same: the pipe diameter, pipe wall thickness, and material of the water inlet and outlet pipes should be the same. At this time, the convective heat transfer coefficients of the liquid in the inlet and outlet pipes and the pipe wall are the same , the heat flux of convective heat transfer is similar;

[0050] The second step is the treatment of the outer wall of the pipe: clean the pipe wall to make it clean and free of stains; if there is a paint film on the pipe wall, polish it smooth to expose the material of the pipe body;

[0051] The third step is the direct contact between the temperature measuring probe and the pipe wall: fasten the temperature measuring probe on the pipe wall with self-adhesive tape and other tying ropes to make it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com