Miniature test clamp used for disk laser device for controlling shell temperature

A technology for testing the temperature of fixtures and shells. It is applied in optical instrument testing, machine/structural component testing, temperature control, etc. It can solve the problems of increasing test time, narrow temperature control range, and large volume of water-cooled plates, and achieves the principle of the device. Simple, short temperature control time and large temperature control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

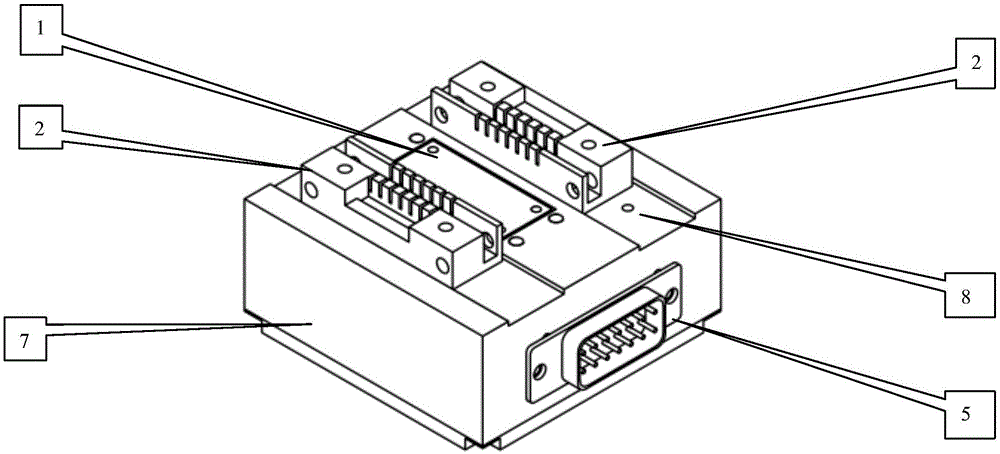

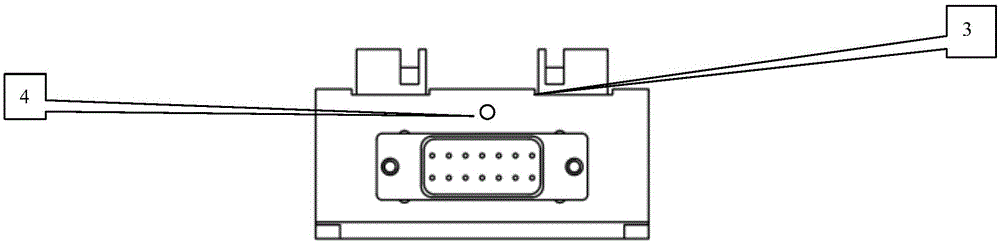

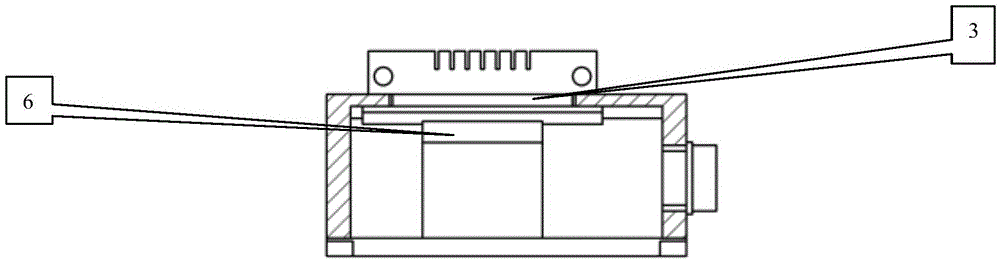

[0023] see figure 1 , figure 2 , image 3 , the whole test device consists of a set of double-row fourteen-pin butterfly laser test fixture 2, a fixture platform 7, a heat-conducting copper block 1, a standard thermistor 4, a thermal insulation gasket 3, a thermoelectric cooler 6, a It consists of DB25 pin interface 5, an LED red and green indicator light 8, a control circuit board, and an LD driving power supply. Depend on Figure 1 It can be seen that the double-row fourteen-pin dish laser fixture 2 and the heat-conducting copper block 1 (the flatness requirement is 0.02mm, the size is 30mm×13mm×2mm) are installed on the fixture platform 7 (the aluminum base, the size is 60mm) by screws ×60mm×24mm) above. Fix the heat-conducting copper block 1, the test clip heat-insulating gasket 3, and the thermoelectric cooler 6 on the fixture platform 7 through plastic screws. Note that the heat-conducting copper block 1 should not be in contact with the fixture platform 7 as much a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com