Method for making speckles for high-temperature deformation testing experiment

A production method and a technology for testing experiments, applied in the field of photomechanics, to achieve the effects of wide sources, low cost, and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

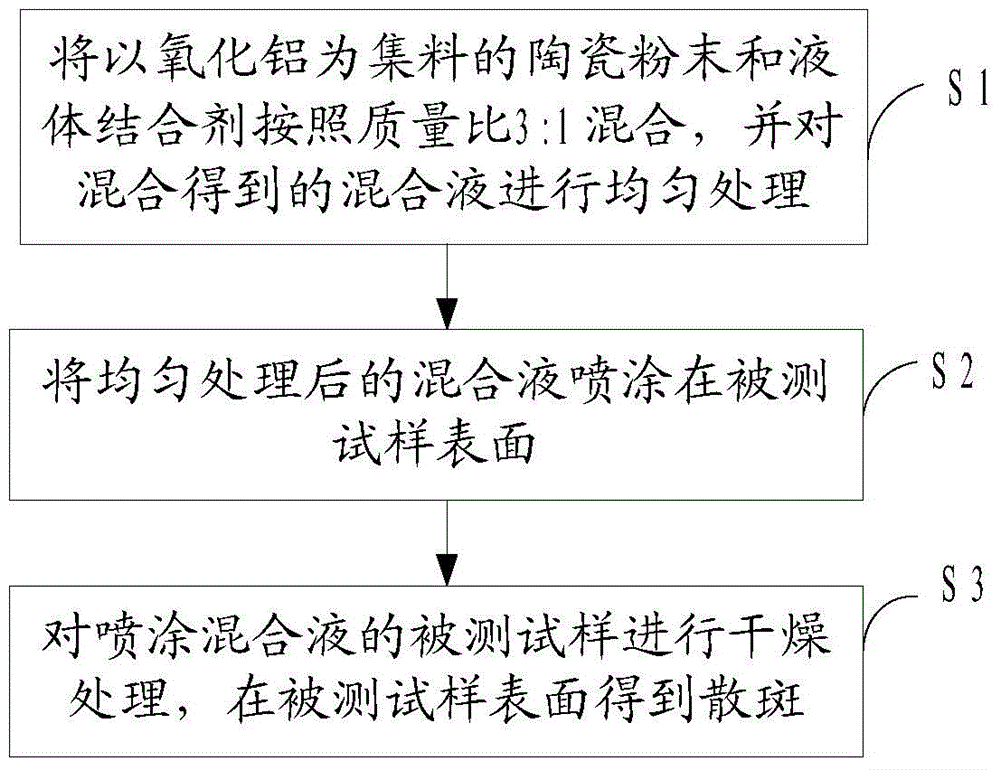

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

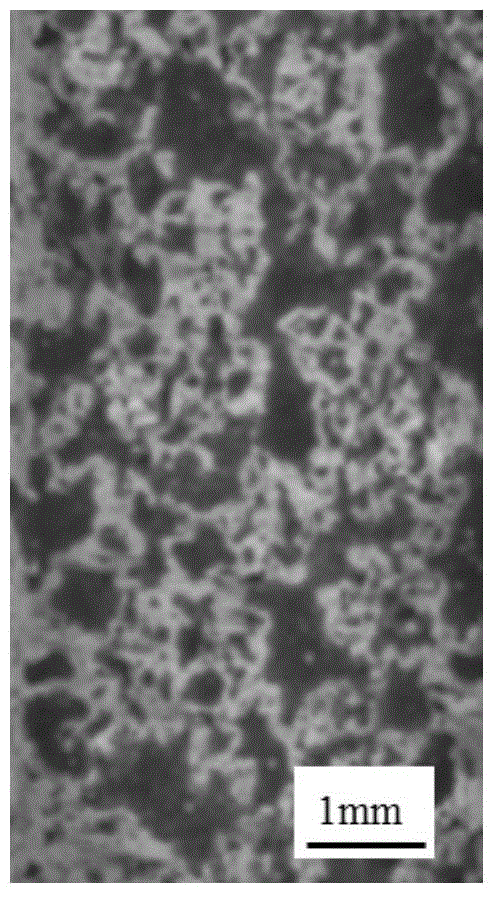

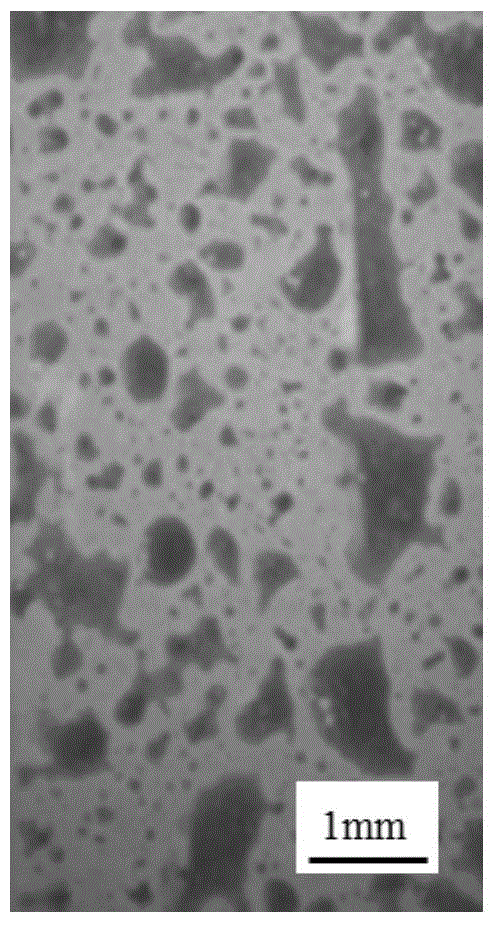

[0037] High-temperature speckle needs to meet the following technical conditions: (1) can withstand high enough temperature; (2) have sufficient adhesion to the surface of the material, and will not fall off under high temperature; (3) ensure simultaneous deformation with the material. The speckle production methods in the prior art are either unable to withstand higher temperatures, or the production process is complicated, or the cost is high, and some productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com